Cat XL Race Buggy Build

- Seabass

- Business Member

- Posts: 1402

- Joined: Mon Jul 27, 2009 8:34 pm

- Location: Mississippi

- Been thanked: 12 times

Cat XL Race Buggy Build

Ok guys I just picked up a CAT which I believe is an XL. I received the car in several pieces and I know I am missing some parts for the car. I took the opportunity to tear down the drive line and look at the car since it was binding and the drag was so severe there is no way the car would operate properly.

My observations:

1. Is the rear diff in the car actually supported by plastic out drives that spin inside plastic cams meant to tighten the rear belts?

2. How the heck are the out drives mounted to the front one way spool? The car came with plastic out drives that are pressed onto the one way bearings. Both out drives have split so they just spin on the one way bearings. I looked at the manual and as I have seen the instructions are worthless, lol.

I will post some pictures of what I am referencing tomorrow but I assume you guys have to know what I am talking about. I may break down and look for a front ball diff for the car.

I am super excited to build a CAT as it is the first Schumacher I have ever owned. I have some plans to machine several parts fot eh car to make it a little more user friendly in accepting modern spurs, etc.

Any input is appreciated.

Jake

My observations:

1. Is the rear diff in the car actually supported by plastic out drives that spin inside plastic cams meant to tighten the rear belts?

2. How the heck are the out drives mounted to the front one way spool? The car came with plastic out drives that are pressed onto the one way bearings. Both out drives have split so they just spin on the one way bearings. I looked at the manual and as I have seen the instructions are worthless, lol.

I will post some pictures of what I am referencing tomorrow but I assume you guys have to know what I am talking about. I may break down and look for a front ball diff for the car.

I am super excited to build a CAT as it is the first Schumacher I have ever owned. I have some plans to machine several parts fot eh car to make it a little more user friendly in accepting modern spurs, etc.

Any input is appreciated.

Jake

-

pedro

- Approved Member

- Posts: 241

- Joined: Thu Jun 12, 2008 4:24 am

- Location: Australia

- Has thanked: 1 time

- Been thanked: 77 times

Re: Cat XL Race Buggy Build

Hi Jake

The rear diff you are referring to is really called the intergrator as the diff is actually on the top layshaft like a six gear rc10 the intergrator adjusts the drive to the front end and can be tightened for more 4wd etc. There should be ball races on those rear outdrives that sit inside the eccentric housings.

As for the front oneways you can drill those outdrives out so that the one way bearings will push in without spreading the plastic and then glue in the bearings (this is for a shelf car only). The front one way spool should have a steel axle running through the centre of it that has an internal thread and the ones ways are secured by c/sunk machine screws.

If the manual you have is really bad you might have an orginal swb manual as they are terrible but later ones can be found on the net. http://www.retromodelisme.com/manuel_page/53/cat-xl-schumacher.html

Peter

The rear diff you are referring to is really called the intergrator as the diff is actually on the top layshaft like a six gear rc10 the intergrator adjusts the drive to the front end and can be tightened for more 4wd etc. There should be ball races on those rear outdrives that sit inside the eccentric housings.

As for the front oneways you can drill those outdrives out so that the one way bearings will push in without spreading the plastic and then glue in the bearings (this is for a shelf car only). The front one way spool should have a steel axle running through the centre of it that has an internal thread and the ones ways are secured by c/sunk machine screws.

If the manual you have is really bad you might have an orginal swb manual as they are terrible but later ones can be found on the net. http://www.retromodelisme.com/manuel_page/53/cat-xl-schumacher.html

Peter

- Incredible_Serious

- Approved Member

- Posts: 3686

- Joined: Tue Jan 29, 2008 12:09 am

- Location: Melbourne, Victoria, Australia

- Has thanked: 1737 times

- Been thanked: 1145 times

Re: Cat XL Race Buggy Build

Jake,

Some thoughts from me.... (after Pedro posted)

You can either try and find new ones (not impossible), or go the front diff option. Depends on how much you want to keep it stock-as-a-rock Cat XL, I guess.....

If you need, as Pedro mentioned, I have the Cat XL and XLS manual in .pdf I could fire through...

Alex

Some thoughts from me.... (after Pedro posted)

The rear "diff" should have bearings either side, that run in plastic eccentric housings bolted to either side of the rear gearbox. The same eccentric housings are used on Cougars too...Seabass wrote:1. Is the rear diff in the car actually supported by plastic out drives that spin inside plastic cams meant to tighten the rear belts?

The one-way hubs are renowned for splitting their plastic holders.... and when they split, you lose the one-way nature of the front end.Seabass wrote: 2. How the heck are the out drives mounted to the front one way spool? The car came with plastic out drives that are pressed onto the one way bearings. Both out drives have split so they just spin on the one way bearings. I looked at the manual and as I have seen the instructions are worthless, lol.

You can either try and find new ones (not impossible), or go the front diff option. Depends on how much you want to keep it stock-as-a-rock Cat XL, I guess.....

If you need, as Pedro mentioned, I have the Cat XL and XLS manual in .pdf I could fire through...

Alex

Osiris is the key.

"The world looks so much better through beer goggles... except Farmer in his underwear" - Ken

Look out for Todd K. - he's a convicted serial killer!!!

"The world looks so much better through beer goggles... except Farmer in his underwear" - Ken

Look out for Todd K. - he's a convicted serial killer!!!

- Seabass

- Business Member

- Posts: 1402

- Joined: Mon Jul 27, 2009 8:34 pm

- Location: Mississippi

- Been thanked: 12 times

Re: Cat XL Race Buggy Build

Thanks for the info guys. I was lucky enough to get an XLS and CAT manual. That link does help a bit more but the pictures still leave alot to be desired. I am hoping to pick up an MMS ball diff for the front and the rear of the car to get rid of that integrator and the front spool.

I am still confused and I apologize for my ignorance. So looking at the out drives on this car and studying the pics closely, I do not see any way bearings would fit inside the eccentric housing. Essentially the plastic out drives appear to rub on the inside of the eccentric housing. If this is the case, I will need to figure out a way to fix this allowing the use of bearings.

I am still confused and I apologize for my ignorance. So looking at the out drives on this car and studying the pics closely, I do not see any way bearings would fit inside the eccentric housing. Essentially the plastic out drives appear to rub on the inside of the eccentric housing. If this is the case, I will need to figure out a way to fix this allowing the use of bearings.

- Incredible_Serious

- Approved Member

- Posts: 3686

- Joined: Tue Jan 29, 2008 12:09 am

- Location: Melbourne, Victoria, Australia

- Has thanked: 1737 times

- Been thanked: 1145 times

Re: Cat XL Race Buggy Build

[quote="Seabass"I am still confused and I apologize for my ignorance. So looking at the out drives on this car and studying the pics closely, I do not see any way bearings would fit inside the eccentric housing. Essentially the plastic out drives appear to rub on the inside of the eccentric housing. If this is the case, I will need to figure out a way to fix this allowing the use of bearings.[/quote]

Mate,

The bearings on the Integrator (and on the diff for other 4wd models and the 2wd range) are 16 x 8 x 5; the 16mm outer diameter fits inside the eccentric housing. The drive shaft outdrives should be smaller than 16mm across, and thus shouldn't rub. I could show you on a 2wd, as the mechanics are much the same, but don't have a 4wd at the moment.

Alex

Mate,

The bearings on the Integrator (and on the diff for other 4wd models and the 2wd range) are 16 x 8 x 5; the 16mm outer diameter fits inside the eccentric housing. The drive shaft outdrives should be smaller than 16mm across, and thus shouldn't rub. I could show you on a 2wd, as the mechanics are much the same, but don't have a 4wd at the moment.

Alex

Osiris is the key.

"The world looks so much better through beer goggles... except Farmer in his underwear" - Ken

Look out for Todd K. - he's a convicted serial killer!!!

"The world looks so much better through beer goggles... except Farmer in his underwear" - Ken

Look out for Todd K. - he's a convicted serial killer!!!

- DerbyDan

- Approved Member

- Posts: 1837

- Joined: Tue Sep 08, 2009 8:04 am

- Location: Northampton UK

- Has thanked: 2 times

- Been thanked: 19 times

Re: Cat XL Race Buggy Build

I'm a big admirer of your work Seabass, so I'm looking forward to seeing how this project progresses knowing that you'll be analysing the car's original design & adding your own improvements along the way

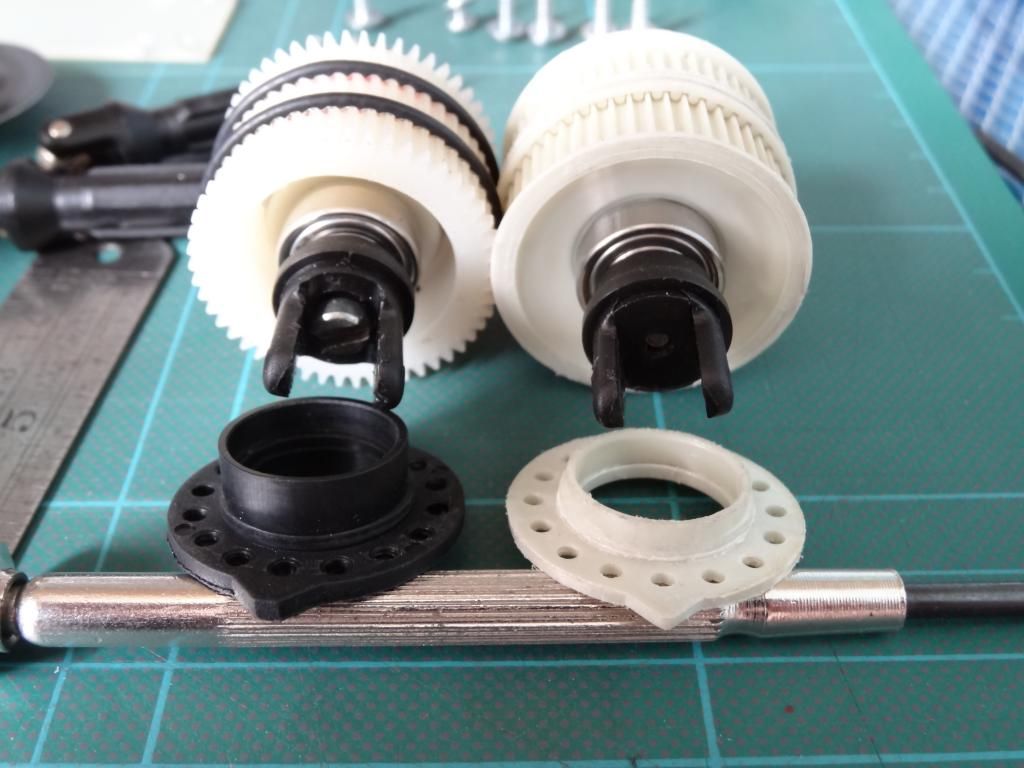

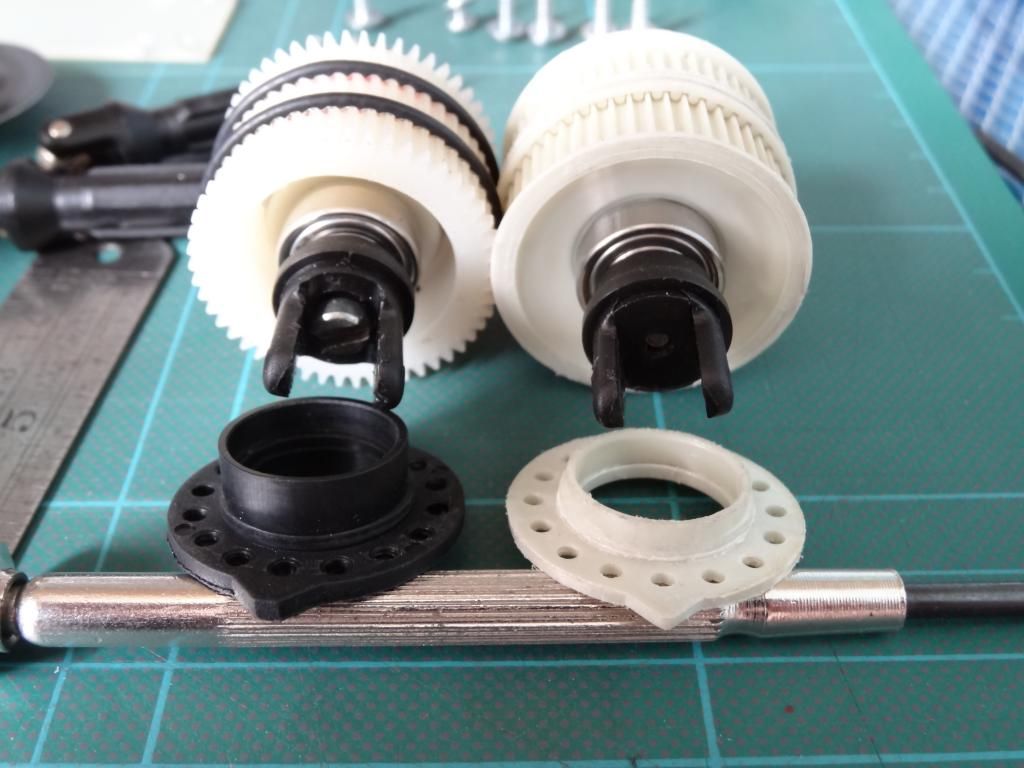

Regarding the rear Diff/Drum pulley - there should be some proper ball races (NMB) set quite deep inside the drum which locate on the eccentric bearing holders, as previously described. Below is a photo of two diffs that I have fitted into my ProCat (& which would fit an XLS) - on the Left is an MMS (Model Motor Sport) diff & on the right is the diff from a comp spec BossCat - you can see the bearings which each run on... it should be the same for an early fixed drum car (with the layshaft integrator)

Regarding the rear Diff/Drum pulley - there should be some proper ball races (NMB) set quite deep inside the drum which locate on the eccentric bearing holders, as previously described. Below is a photo of two diffs that I have fitted into my ProCat (& which would fit an XLS) - on the Left is an MMS (Model Motor Sport) diff & on the right is the diff from a comp spec BossCat - you can see the bearings which each run on... it should be the same for an early fixed drum car (with the layshaft integrator)

My T.C Showroom; http://www.tamiyaclub.com/member.asp?id=28990

-

Peakey

- Approved Member

- Posts: 578

- Joined: Tue Feb 25, 2014 3:55 am

- Location: Nottingham, UK

- Been thanked: 3 times

Re: Cat XL Race Buggy Build

Welcome to the world of the Schumacher, there's no going back now. There not the essayist cars to work on but there great cars, if there's anything you need Jake give me a shout I've got a few XLS parts and if you need them I've got some new front spools.

- Seabass

- Business Member

- Posts: 1402

- Joined: Mon Jul 27, 2009 8:34 pm

- Location: Mississippi

- Been thanked: 12 times

Re: Cat XL Race Buggy Build

That picture makes perfect sense not, thank you very much. The car came partially assembled and was done so impropery so that is why my judgement is way off right now. Yes I am looking forward to making the car an occasional racer that will be fun to drive as well as work the way I want it too. Stay tuned as this is only the planning phase.

Thanks Justin, I am certain I will be on the lookout for parts down the road.

JAke

Thanks Justin, I am certain I will be on the lookout for parts down the road.

JAke

- Seabass

- Business Member

- Posts: 1402

- Joined: Mon Jul 27, 2009 8:34 pm

- Location: Mississippi

- Been thanked: 12 times

Re: Cat XL Race Buggy Build

I messed around with the car again trying to figure why the drive train had so much drag and I found the problem. The two eccentric housings that press around the bearings were completely worn out and did not support the integrator bearings, causing the out drives to rub on the inside of the eccentric housings.

I happened to have two new ones in the bags of parts installed them and the drive train completely loosened up and can actually turn like it should. I just bought a front and rear MMS diff for the car.

I really hate the top shaft on the car, and how it seems to sandwich the pulleys, causing undue drag. Since I am getting rid of that integrator and installing a ball diff, I have plans for a new top shaft to free up the tensioned caused when tightening the diff on the current top shaft.

I just finished some drawings for a new chassis which will allow me to use a shorty lipo battery in the car. I still have a few other things I want to address but taking baby steps at this point. This is going to be a pretty expensive car by the time its done and I hope it ends up being a pretty decent car to run. More to follow.

Jake

I happened to have two new ones in the bags of parts installed them and the drive train completely loosened up and can actually turn like it should. I just bought a front and rear MMS diff for the car.

I really hate the top shaft on the car, and how it seems to sandwich the pulleys, causing undue drag. Since I am getting rid of that integrator and installing a ball diff, I have plans for a new top shaft to free up the tensioned caused when tightening the diff on the current top shaft.

I just finished some drawings for a new chassis which will allow me to use a shorty lipo battery in the car. I still have a few other things I want to address but taking baby steps at this point. This is going to be a pretty expensive car by the time its done and I hope it ends up being a pretty decent car to run. More to follow.

Jake

-

rraeford

- Approved Member

- Posts: 228

- Joined: Fri Oct 16, 2009 10:52 am

- Location: Savannah, Ga

- Been thanked: 8 times

Re: Cat XL Race Buggy Build

I like top deck but I have a question. When I ran this car BITD, one of the biggest issues was keeping dirt out of the drivetrain. The Schumacher belt is fine compared to a Yoke or Optima and dirt getting onto the teeth of the front pulley was ruinous. My only reason for pointing this out is that by cutting out the holes in the top plate, the dust cover is no longer going to do much to protect the drivetrain. Any thoughts on this?

- Seabass

- Business Member

- Posts: 1402

- Joined: Mon Jul 27, 2009 8:34 pm

- Location: Mississippi

- Been thanked: 12 times

Re: Cat XL Race Buggy Build

Well since this is my first CAT I have no experience with the car and I could see how the small pitch of the pulleys and belt could possibly build up dirt causing the belt to skip terribly. The great news is my local track is a carpet offroad facility so I should not any issues as long as I clean the carpet particles which build up after a race day.

Most tracks in the US are hard pack facilities that have very little dust however there are still tracks out there that do have loose surfaces. I guess the only thing to do is run the car to find out. I could always just skip the step of machining the cutouts on the top deck and help curb the issue if it is a problem. Thanks for the input.

My top shaft should turn out pretty good, I have the design in my head, I just need to start up the machine to test my theory.

Jake

Most tracks in the US are hard pack facilities that have very little dust however there are still tracks out there that do have loose surfaces. I guess the only thing to do is run the car to find out. I could always just skip the step of machining the cutouts on the top deck and help curb the issue if it is a problem. Thanks for the input.

My top shaft should turn out pretty good, I have the design in my head, I just need to start up the machine to test my theory.

Jake

-

rraeford

- Approved Member

- Posts: 228

- Joined: Fri Oct 16, 2009 10:52 am

- Location: Savannah, Ga

- Been thanked: 8 times

Re: Cat XL Race Buggy Build

Yeah, I see your point about modern tracks. In the 80's, every track was loose dirt. Nobody knew what a blue groove was. Now it may not be an issue. The great thing about CATs is they are super nimble and quick. Bearings will also fair better in a low dust environment. Mine wasn't a great jumper but jumps weren't the same then.

-

Peakey

- Approved Member

- Posts: 578

- Joined: Tue Feb 25, 2014 3:55 am

- Location: Nottingham, UK

- Been thanked: 3 times

Re: Cat XL Race Buggy Build

I am really intreaged by you thought on the top shaft Jake, the intergrator is totally different to the other layshafts as they just run on the bearings and the main belt just skips over it unless it's a MMS or such that's had a centre gear machined in it.

As for the top deck I prefer mine

I ran it on Sunday the only eel problem I had is I didn't put enough of a chamfer on the rear of the chassis and snapped the main belt after 2 runs

As for dust I was running on astro outdoor I had a bit of sand in but unless you really seal your undertray correctly your gonna get dust and crap in there. If you keep on top of blowing it out like jake said I woudnt really worry about it

My chassis can take shorty and saddles but I can only just fit it all in with a shorty so I don't think I'll get saddles in

As for the top deck I prefer mine

I ran it on Sunday the only eel problem I had is I didn't put enough of a chamfer on the rear of the chassis and snapped the main belt after 2 runs

As for dust I was running on astro outdoor I had a bit of sand in but unless you really seal your undertray correctly your gonna get dust and crap in there. If you keep on top of blowing it out like jake said I woudnt really worry about it

My chassis can take shorty and saddles but I can only just fit it all in with a shorty so I don't think I'll get saddles in

Create an account or sign in to join the discussion

You need to be a member in order to post a reply

Create an account

Not a member? register to join our community

Members can start their own topics & subscribe to topics

It’s free and only takes a minute

Sign in

-

- Similar Topics

- Replies

- Views

- Last post

-

- 17 Replies

- 3555 Views

-

Last post by isobarik

-

- 7 Replies

- 2266 Views

-

Last post by Bormac

-

- 5 Replies

- 1235 Views

-

Last post by Lonestar

-

- 3 Replies

- 879 Views

-

Last post by JosephS

-

- 4 Replies

- 1057 Views

-

Last post by Charlie don't surf

-

- 11 Replies

- 1632 Views

-

Last post by GeekSpeed

-

- 1 Replies

- 3403 Views

-

Last post by Mr. ED

-

- 5 Replies

- 2360 Views

-

Last post by xxxmain

Who is online

Users browsing this forum: No registered users and 5 guests