Thanks for that. I wasn't aware that Ampro offered chassis braces for this model. I'm definitely gonna investigate those further.

Meanwhile, I'll try to keep the extreme crashing to a minimum.

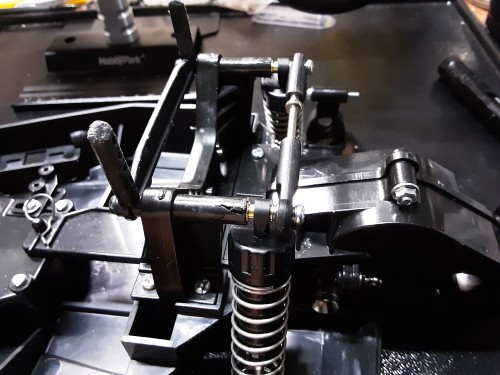

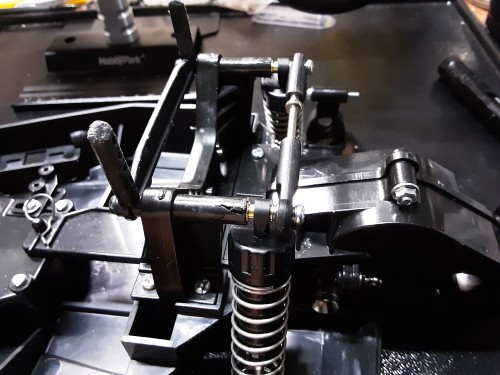

By the way, while I was installing the rear shock's top screws, I noticed they bottom out before tightening against the brass tube. The kit supplies 15mm long screws but the hole isn't deep enough to accept this length; it leaves about 1 - 1.5mm gap at the tube.

The moment I noticed this I remembered this photo you posted. I wonder if a previous owner tried to force the screw tight against the tube and that created stress that eventually lead to the cracks.

- 20210720_155048.jpg (52.23 KiB) Viewed 1433 times

- 20210720_155048.jpg (52.23 KiB) Viewed 1433 times

Anyway, I'm on a self imposed budget with this one (I really don't want to spend anything more on it) so I think I'm gonna make a simple brace from some scrap G10 to span between the two shock mounts - similar to your turn buckles. Not only will this add some much needed bracing, it will take up some or all of the excess screw length. If there's any slop remaining, I will grind the screws to make them a little shorter.

Your suggestion about switching to machine screws is spot on. In fact, I wonder if these cars wouldn't benefit from having all the holes tapped for machine screws - especially when threading into hard plastic. I tend to think those kit supplied self-tapping screws create problems down the road as the plastic ages and becomes more brittle.

Anyway, thanks for the advice.