Factory Works/A&L C2 build...

- GoMachV

- Approved Member

- Posts: 12183

- Joined: Sun Apr 29, 2012 10:31 pm

- Location: Twin Falls, ID

- Has thanked: 1080 times

- Been thanked: 3729 times

Re: Factory Works/A&L C2 build...

The C2.1 is a modern twist on the C2, you could do something similar but with the vintage style chassis I don't know how it would look

- NomadRacer

- Approved Member

- Posts: 1467

- Joined: Sun Apr 16, 2017 7:29 am

- Location: Eastern Shore of Virginia

- Has thanked: 81 times

- Been thanked: 79 times

Re: Factory Works/A&L C2 build...

Heck man, now I will have to go back to thinking again after I get the buggy back together again. I have it broken down so I can drill for the servo mounts . I made, sort of a wooden "jig plate" to go in my drill press vise today. Giving it a day for the glue to cure.

Waiting on the rear axles to arrive via USPS. They were so close Saturday, 150 miles away at the sort facility. Now the package made an abrupt turn and went to SC.

Waiting on the rear axles to arrive via USPS. They were so close Saturday, 150 miles away at the sort facility. Now the package made an abrupt turn and went to SC.

Bum on Direct Deposit

- NomadRacer

- Approved Member

- Posts: 1467

- Joined: Sun Apr 16, 2017 7:29 am

- Location: Eastern Shore of Virginia

- Has thanked: 81 times

- Been thanked: 79 times

Re: Factory Works/A&L C2 build...

The servo mounting holes are drilled in the chassis now. I don't have the proper 82 degree countersink bit (yet) so using some button head screws from the bottom for now so I can move on.

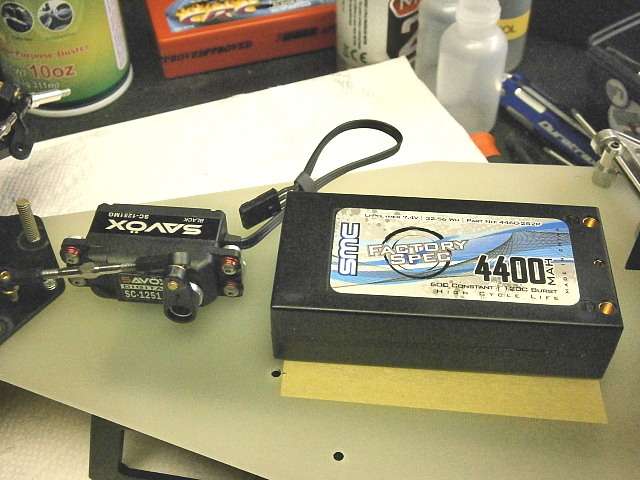

Waiting for some black (ASC 6334) battery cups to arrive in order to get the shorty lipo battery in place. As per GoMachV's advice, mount it as far forward as possible.

All the rear axle parts are on hand now. I tried to score a pair of the re-release black dogbones but was only able to source one. After much searching, I found some new old stock ones. I have a back order at a couple of places.

I've decided to go old school with a brushed motor and a lipo capable ESC. More on that later on.

Waiting for some black (ASC 6334) battery cups to arrive in order to get the shorty lipo battery in place. As per GoMachV's advice, mount it as far forward as possible.

All the rear axle parts are on hand now. I tried to score a pair of the re-release black dogbones but was only able to source one. After much searching, I found some new old stock ones. I have a back order at a couple of places.

I've decided to go old school with a brushed motor and a lipo capable ESC. More on that later on.

Bum on Direct Deposit

- lmw94002

- Approved Member

- Posts: 349

- Joined: Mon Nov 28, 2016 10:43 am

- Location: Boston, MA, USA

- Been thanked: 7 times

Re: Factory Works/A&L C2 build...

One trick you can try to darken steel dogones...

Clean the steel bones up real good. Heat them up in the oven to like 450 for awhile... then quench them in dirty motor oil. Gives them a decent black finish. And being "oiled" like that helps prevent rust in the short term. You can quench in "clean oil", but then often you get more of a brown-ish finish.

I had a photo somewhere ...

Clean the steel bones up real good. Heat them up in the oven to like 450 for awhile... then quench them in dirty motor oil. Gives them a decent black finish. And being "oiled" like that helps prevent rust in the short term. You can quench in "clean oil", but then often you get more of a brown-ish finish.

I had a photo somewhere ...

--

RC10CE 6-gear, RC10 Team, 10L, 10LSS, Worlds, B2, B4 TC, FT TC3, Nitro SC8, SC18, RC18LM, FT SC10.2, Worlds-ReRe, B6, B6D

--Builds--

SSC10 build - http://www.rc10talk.com/viewtopic.php?f=88&t=41740

RC10CE 6-gear, RC10 Team, 10L, 10LSS, Worlds, B2, B4 TC, FT TC3, Nitro SC8, SC18, RC18LM, FT SC10.2, Worlds-ReRe, B6, B6D

--Builds--

SSC10 build - http://www.rc10talk.com/viewtopic.php?f=88&t=41740

- GoMachV

- Approved Member

- Posts: 12183

- Joined: Sun Apr 29, 2012 10:31 pm

- Location: Twin Falls, ID

- Has thanked: 1080 times

- Been thanked: 3729 times

Re: Factory Works/A&L C2 build...

If you haven't already sourced them, you'll need 3/16 x 3/8 flanged bearings for those axles to work.

I forgot to reply with the countersink bit I use. This is the one I prefer. Thought it was from McMaster but that was the previous one

https://www.ebay.com/itm/222092837465

I forgot to reply with the countersink bit I use. This is the one I prefer. Thought it was from McMaster but that was the previous one

https://www.ebay.com/itm/222092837465

- NomadRacer

- Approved Member

- Posts: 1467

- Joined: Sun Apr 16, 2017 7:29 am

- Location: Eastern Shore of Virginia

- Has thanked: 81 times

- Been thanked: 79 times

Re: Factory Works/A&L C2 build...

Thank you for the tip, much appreciated.

I will get into seeing how things go together later on today. I'm hoping I've bought all the right parts. I have a habit of not doing that lately.

I will get into seeing how things go together later on today. I'm hoping I've bought all the right parts. I have a habit of not doing that lately.

Bum on Direct Deposit

- lmw94002

- Approved Member

- Posts: 349

- Joined: Mon Nov 28, 2016 10:43 am

- Location: Boston, MA, USA

- Been thanked: 7 times

Re: Factory Works/A&L C2 build...

Wouldn't the classic wheel conversion kit be easier? Albeit you still need the dogbones... Or did I miss something?

--

RC10CE 6-gear, RC10 Team, 10L, 10LSS, Worlds, B2, B4 TC, FT TC3, Nitro SC8, SC18, RC18LM, FT SC10.2, Worlds-ReRe, B6, B6D

--Builds--

SSC10 build - http://www.rc10talk.com/viewtopic.php?f=88&t=41740

RC10CE 6-gear, RC10 Team, 10L, 10LSS, Worlds, B2, B4 TC, FT TC3, Nitro SC8, SC18, RC18LM, FT SC10.2, Worlds-ReRe, B6, B6D

--Builds--

SSC10 build - http://www.rc10talk.com/viewtopic.php?f=88&t=41740

- GoMachV

- Approved Member

- Posts: 12183

- Joined: Sun Apr 29, 2012 10:31 pm

- Location: Twin Falls, ID

- Has thanked: 1080 times

- Been thanked: 3729 times

Re: Factory Works/A&L C2 build...

Wrong bearings, that's why they give you new hubs.

3/16 axles didn't exist in the days of these trailing arms

3/16 axles didn't exist in the days of these trailing arms

- lmw94002

- Approved Member

- Posts: 349

- Joined: Mon Nov 28, 2016 10:43 am

- Location: Boston, MA, USA

- Been thanked: 7 times

Re: Factory Works/A&L C2 build...

Duh, that's the context I was forgetting about... the trailing arms. My bad.

--

RC10CE 6-gear, RC10 Team, 10L, 10LSS, Worlds, B2, B4 TC, FT TC3, Nitro SC8, SC18, RC18LM, FT SC10.2, Worlds-ReRe, B6, B6D

--Builds--

SSC10 build - http://www.rc10talk.com/viewtopic.php?f=88&t=41740

RC10CE 6-gear, RC10 Team, 10L, 10LSS, Worlds, B2, B4 TC, FT TC3, Nitro SC8, SC18, RC18LM, FT SC10.2, Worlds-ReRe, B6, B6D

--Builds--

SSC10 build - http://www.rc10talk.com/viewtopic.php?f=88&t=41740

- NomadRacer

- Approved Member

- Posts: 1467

- Joined: Sun Apr 16, 2017 7:29 am

- Location: Eastern Shore of Virginia

- Has thanked: 81 times

- Been thanked: 79 times

Re: Factory Works/A&L C2 build...

Yep, got the 3/16 x 3/8 flanged bearings bearings already installed in the trailing arms.GoMachV wrote: ↑Mon May 15, 2017 1:20 pm If you haven't already sourced them, you'll need 3/16 x 3/8 flanged bearings for those axles to work.

I forgot to reply with the countersink bit I use. This is the one I prefer. Thought it was from McMaster but that was the previous one

https://www.ebay.com/itm/222092837465

Thanks for the link, just bought the countersink bit. I've dealt with that seller numerous times and he's always quick to ship stuff.

lmw94002 - That's what I got, ASC 6802 classic wheel conversion kit. it came with 3/16 x 3/8 unflanged bearings. I can always use them for front wheel bearings. I also have the 6372 dogbone springs & spacers and 6370 dogbones.

Bum on Direct Deposit

- NomadRacer

- Approved Member

- Posts: 1467

- Joined: Sun Apr 16, 2017 7:29 am

- Location: Eastern Shore of Virginia

- Has thanked: 81 times

- Been thanked: 79 times

Re: Factory Works/A&L C2 build...

Oh man, things are just working out with these axles...

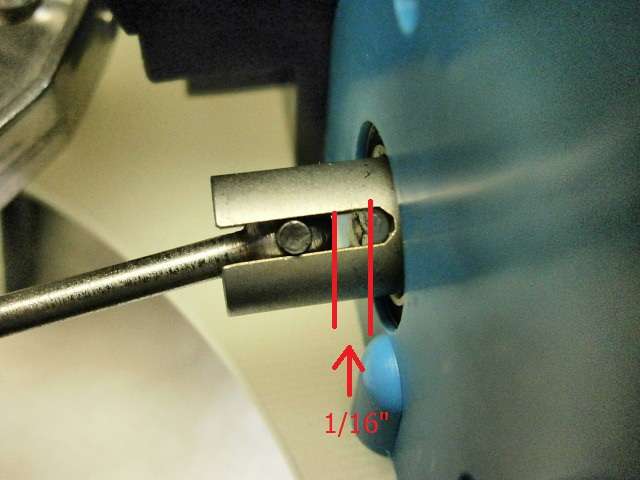

I have the axle in the trailing arm with no shims, 1/8" down stop in the shock. I can't put the spacer that came in the dogbone springs & spacer kit without the dogbone binding in the transmission out drive . there's also no room for the spring. In the picture you can see, I only have 1/16" to play with. Do I have the wrong parts to make this work?

I have the axle in the trailing arm with no shims, 1/8" down stop in the shock. I can't put the spacer that came in the dogbone springs & spacer kit without the dogbone binding in the transmission out drive . there's also no room for the spring. In the picture you can see, I only have 1/16" to play with. Do I have the wrong parts to make this work?

Bum on Direct Deposit

- GoMachV

- Approved Member

- Posts: 12183

- Joined: Sun Apr 29, 2012 10:31 pm

- Location: Twin Falls, ID

- Has thanked: 1080 times

- Been thanked: 3729 times

- jwscab

- Approved Member

- Posts: 6570

- Joined: Wed Jan 28, 2009 9:42 am

- Location: Chalfont, PA

- Has thanked: 16 times

- Been thanked: 498 times

Re: Factory Works/A&L C2 build...

you shouldn't need the springs or spacers. I would put the bones in with nothing and see if there is any binding with the bone floating. Then if so, add a shock o-ring on one side to keep the bone in the right position.

- NomadRacer

- Approved Member

- Posts: 1467

- Joined: Sun Apr 16, 2017 7:29 am

- Location: Eastern Shore of Virginia

- Has thanked: 81 times

- Been thanked: 79 times

Re: Factory Works/A&L C2 build...

Wow. you guys have saved me! I was thinking I'd have to spend more of my meager hobby funds on re-release Worlds CVD axles. I'll bust out some red shock o-rings and try again to get it right.

Ok, tried the red o-ring and the dogbone was binding. I put two .010" shims on the axle and there's no binding at full travel. I'll go with that!

Ok, tried the red o-ring and the dogbone was binding. I put two .010" shims on the axle and there's no binding at full travel. I'll go with that!

Bum on Direct Deposit

- NomadRacer

- Approved Member

- Posts: 1467

- Joined: Sun Apr 16, 2017 7:29 am

- Location: Eastern Shore of Virginia

- Has thanked: 81 times

- Been thanked: 79 times

Re: Factory Works/A&L C2 build...

I cleaned up the dogbones ( a little rust in spots) with a dremel wire wheel, cleaned with acetone and applied a treatment of EEZOX to help prevent rust. This stuff is great, been using it for years on all types of stuff.

I think I'll work on the battery cups next... do a little cutting and shaping.

I think I'll work on the battery cups next... do a little cutting and shaping.

Bum on Direct Deposit

Create an account or sign in to join the discussion

You need to be a member in order to post a reply

Create an account

Not a member? register to join our community

Members can start their own topics & subscribe to topics

It’s free and only takes a minute

Sign in

-

- Similar Topics

- Replies

- Views

- Last post

-

- 22 Replies

- 4088 Views

-

Last post by XLR8

-

- 69 Replies

- 10149 Views

-

Last post by XLR8

-

- 15 Replies

- 4837 Views

-

Last post by scr8p

-

- 115 Replies

- 24536 Views

-

Last post by NomadRacer

-

- 16 Replies

- 1758 Views

-

Last post by sandkil

-

- 1 Replies

- 3256 Views

-

Last post by NomadRacer

-

- 16 Replies

- 4358 Views

-

Last post by NomadRacer

-

- 3 Replies

- 1306 Views

-

Last post by mk-Zero

Who is online

Users browsing this forum: ![]() pedro and 20 guests

pedro and 20 guests