Mugen BULLDOG mods.

- besty22

- Approved Member

- Posts: 347

- Joined: Tue Sep 02, 2008 8:21 am

- Location: Central Coast NSW Australia

Re: Mugen BULLDOG mods.

PRP. From memory there is a small grub screw which controls hardness of the air damper. It is in the damper mount. I will confirm this at home tonight.

Respect - Hard Earned but Easily Lost

- prp

- Approved Member

- Posts: 665

- Joined: Sun Dec 10, 2006 4:27 pm

- Location: Lyon FRANCE

- Been thanked: 13 times

- Bormac

- Approved Member

- Posts: 3113

- Joined: Wed Sep 05, 2007 3:52 pm

- Location: CENTRAL COAST, NSW AUSTRALIA

- Has thanked: 21 times

- Been thanked: 11 times

Re: Mugen BULLDOG mods.

I have recently stripped down both of the Mugen Bulldog's which I have left wanting to get both these cars sorted out once and for all. What I mean by this is I have had some ideas that I wanted to implement the same modifications to both cars. I figured I'd post up some pics for you to look over.

Clearly I am not an engineer nor am I an expert machinist. I have set about doing the best I can with the tools and materials I have available to me. What this means is that you also could use some of these mods on your car if they are of interest you.

Basicaly I didn't want to modernize my cars but rather use some ideas that the guys did or could have done back in the day when these cars were out on the race track.

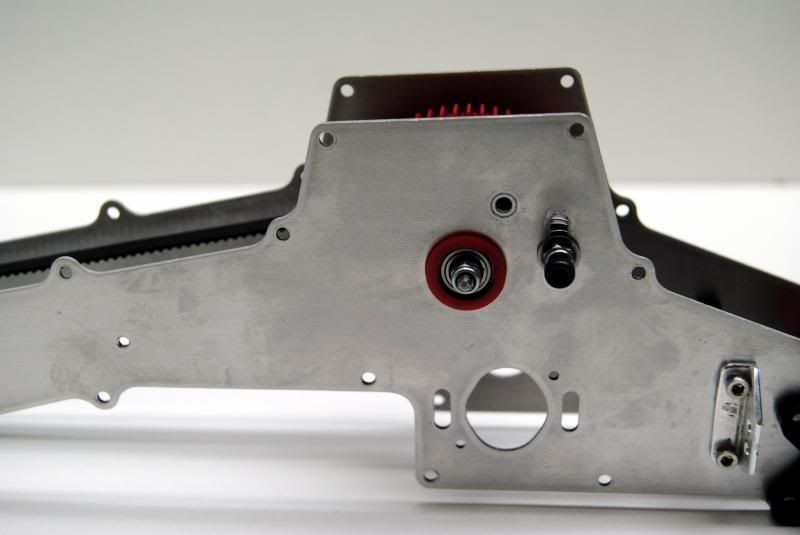

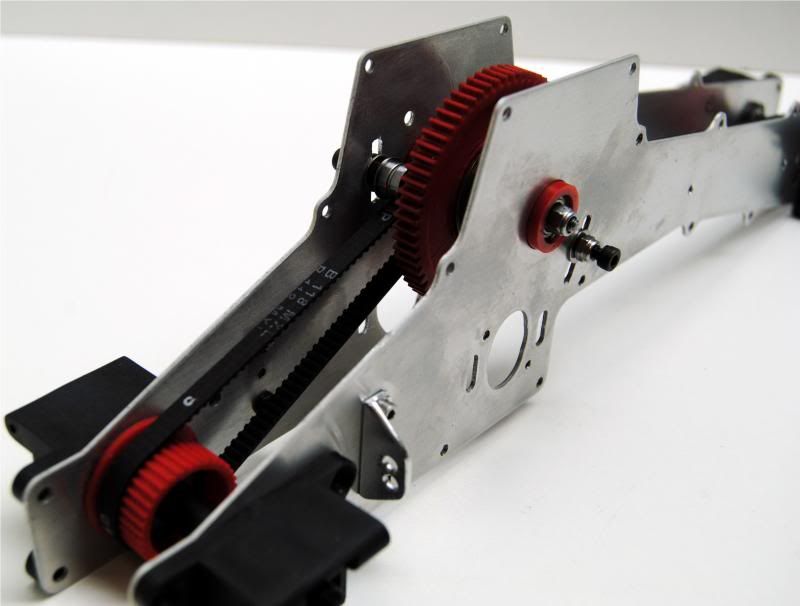

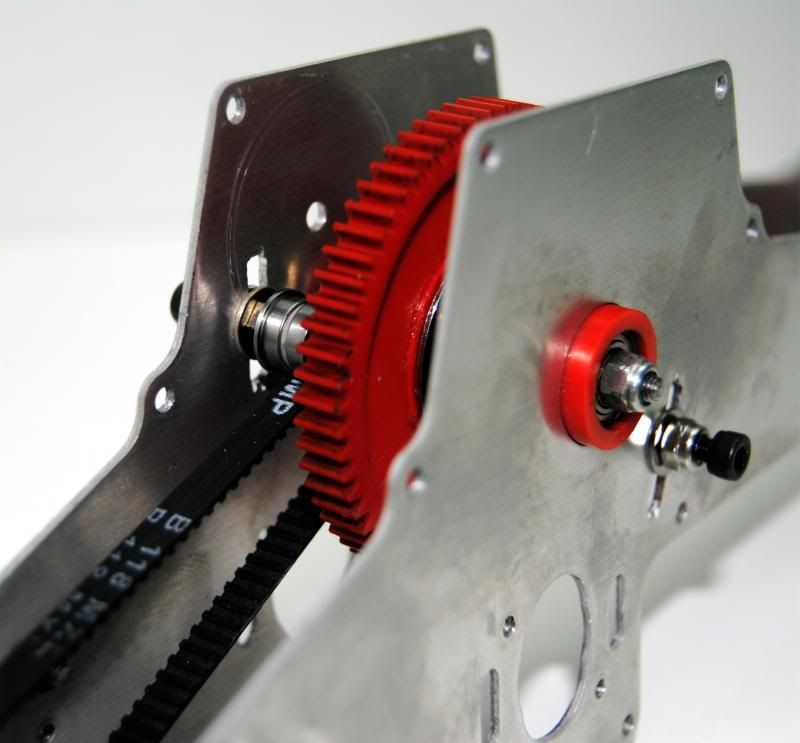

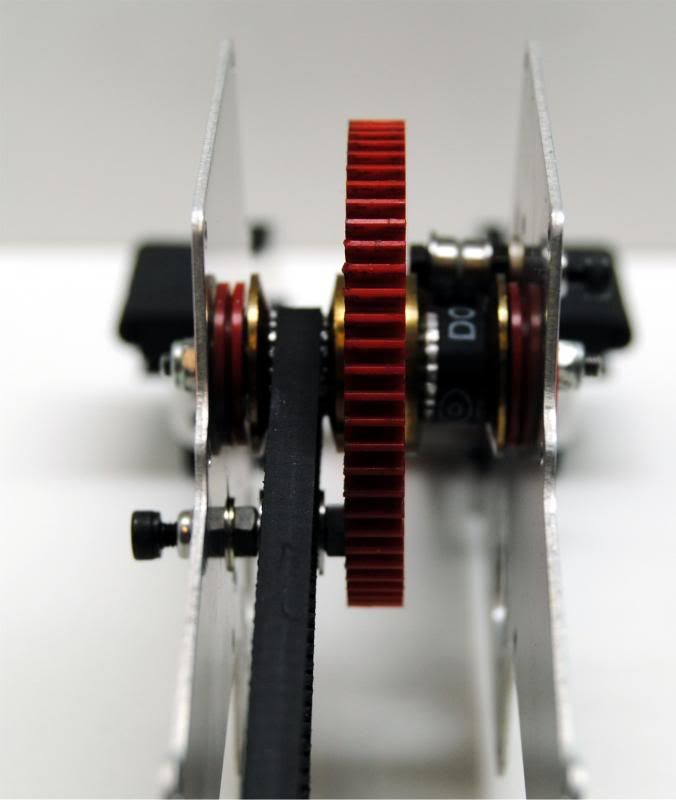

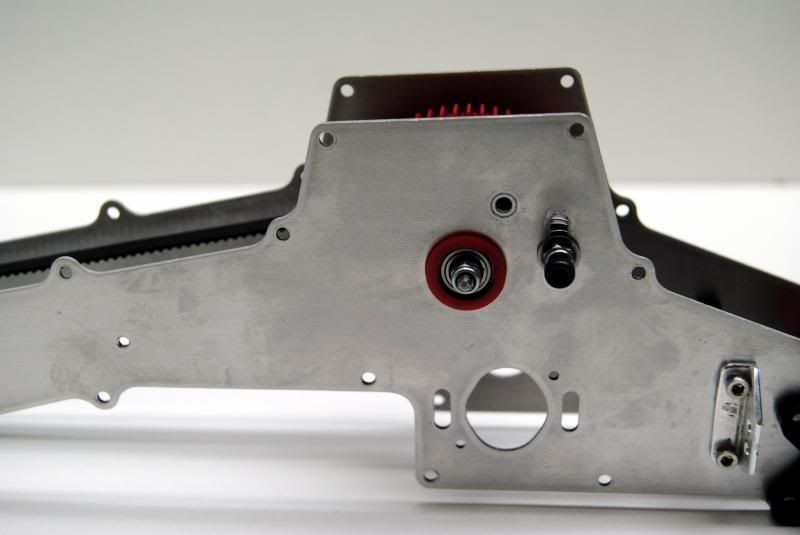

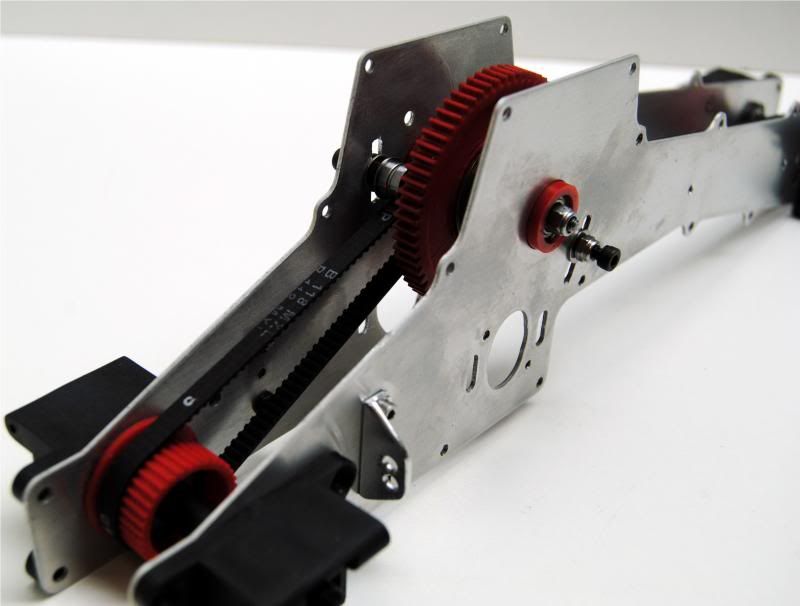

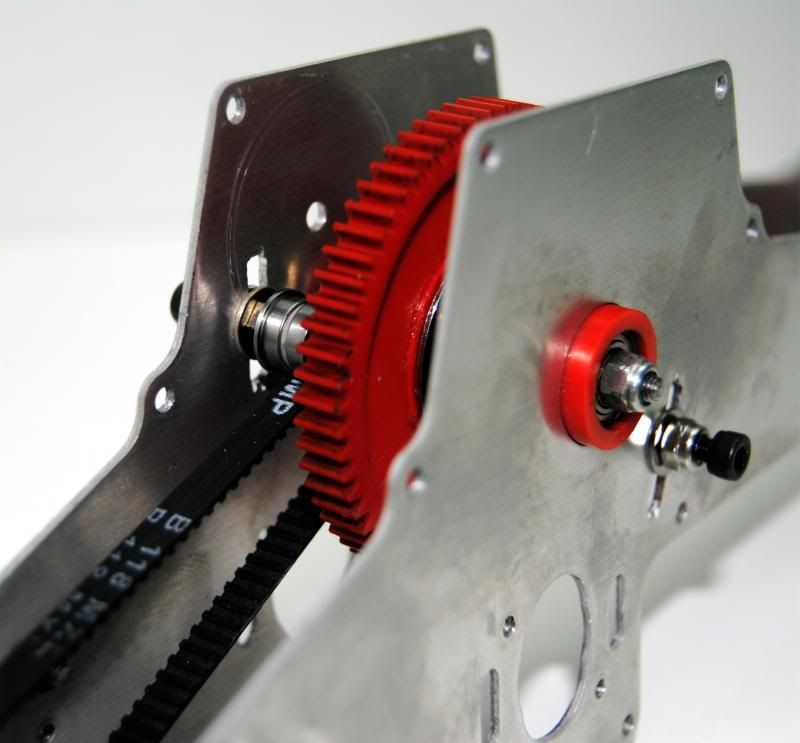

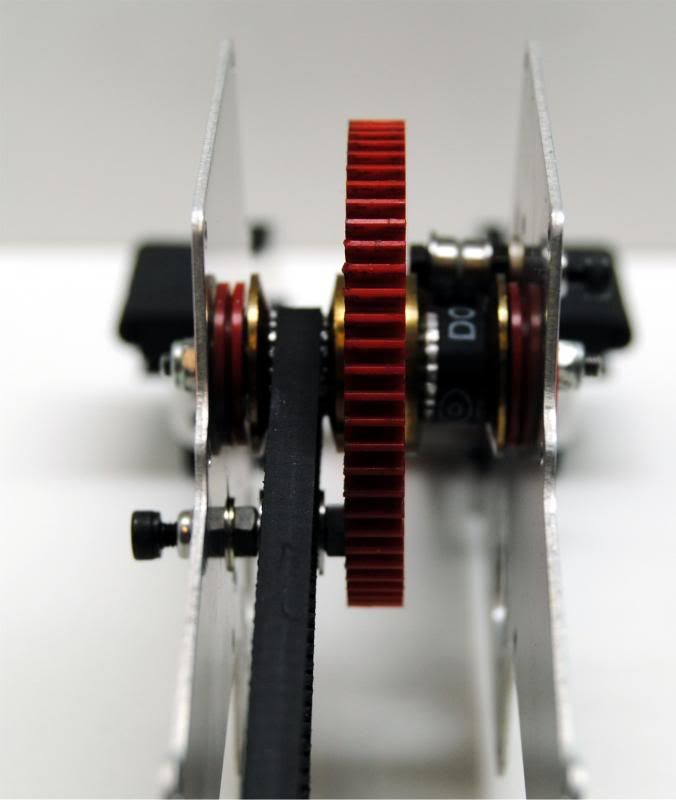

Belt tensioning system.

From experience anything more than an old stock motor and nicads would produce belt slipage. For me the drive componants are too hard to find now days and once teeth are rounded over it's common even for new belts to slip and continue wear on the belt pulleys. I have experimented with a few ways to add a tensioning sytstem but for me this one has worked the best.

The concept was simple, create a slot in each side of the alloy chassis plate which can allow a single M3 screw to slide back and forth. On the inside of the chassis a pair of flanged bearings are fastened onto the M3 screw allowing the bearings to roll down over the top (flat side) of the belt. The adjustment slots allow enough room to release and add tension as required. It's a simple system that works well for me. I have been running a 12T brushless system and there has been no slip at all.

Clearly I am not an engineer nor am I an expert machinist. I have set about doing the best I can with the tools and materials I have available to me. What this means is that you also could use some of these mods on your car if they are of interest you.

Basicaly I didn't want to modernize my cars but rather use some ideas that the guys did or could have done back in the day when these cars were out on the race track.

Belt tensioning system.

From experience anything more than an old stock motor and nicads would produce belt slipage. For me the drive componants are too hard to find now days and once teeth are rounded over it's common even for new belts to slip and continue wear on the belt pulleys. I have experimented with a few ways to add a tensioning sytstem but for me this one has worked the best.

The concept was simple, create a slot in each side of the alloy chassis plate which can allow a single M3 screw to slide back and forth. On the inside of the chassis a pair of flanged bearings are fastened onto the M3 screw allowing the bearings to roll down over the top (flat side) of the belt. The adjustment slots allow enough room to release and add tension as required. It's a simple system that works well for me. I have been running a 12T brushless system and there has been no slip at all.

- Bormac

- Approved Member

- Posts: 3113

- Joined: Wed Sep 05, 2007 3:52 pm

- Location: CENTRAL COAST, NSW AUSTRALIA

- Has thanked: 21 times

- Been thanked: 11 times

Re: Mugen BULLDOG mods.

I'm still yet to experiment with the centre ball diff. I have been running it locked up.

- Bormac

- Approved Member

- Posts: 3113

- Joined: Wed Sep 05, 2007 3:52 pm

- Location: CENTRAL COAST, NSW AUSTRALIA

- Has thanked: 21 times

- Been thanked: 11 times

- Coelacanth

- Approved Member

- Posts: 7421

- Joined: Thu Jul 29, 2010 6:20 pm

- Location: Alberta, Canada

- Has thanked: 16 times

- Been thanked: 325 times

Re: Mugen BULLDOG mods.

Nice mod, Jason. You might consider swapping out the washer + nylon lock-nut for a flanged lock-nut, that should prevent any up-down slippage--if that ends up being a concern.

Completed projects: CYANide Onroad Optima | Zebra Gold Optima | Barney Optima | OptiMutt RWD Mid

Gallery - Coel's Stalls: Marui Galaxy & Shogun Resto-Mods | FrankenBuff AYK Buffalo | 1987 Buick GNX RC12L3

Gallery - Coel's Stalls: Marui Galaxy & Shogun Resto-Mods | FrankenBuff AYK Buffalo | 1987 Buick GNX RC12L3

- prp

- Approved Member

- Posts: 665

- Joined: Sun Dec 10, 2006 4:27 pm

- Location: Lyon FRANCE

- Been thanked: 13 times

Re: Mugen BULLDOG mods.

Hi Jason

Normally, you must put the belt tensioner under for the rear belt and on the belt for the front.

The belt force more on the belt tensioner on yours...

Normally, you must put the belt tensioner under for the rear belt and on the belt for the front.

The belt force more on the belt tensioner on yours...

- Bormac

- Approved Member

- Posts: 3113

- Joined: Wed Sep 05, 2007 3:52 pm

- Location: CENTRAL COAST, NSW AUSTRALIA

- Has thanked: 21 times

- Been thanked: 11 times

Re: Mugen BULLDOG mods.

Hi Marc. Thanks for the suggestion as it is a good one. I'd prefer not to use a serrated nuts though as this could create a 'memory' spot on the slot. The washers I've used on the out side are quite sturdy and you'd be surprised just how tight these adjusters do up. I've been running a Hobbywing brushless 13T system and I have not had any trouble yet.Coelacanth wrote:Nice mod, Jason. You might consider swapping out the washer + nylon lock-nut for a flanged lock-nut, that should prevent any up-down slippage--if that ends up being a concern.

I do appreciate your input though.

- Bormac

- Approved Member

- Posts: 3113

- Joined: Wed Sep 05, 2007 3:52 pm

- Location: CENTRAL COAST, NSW AUSTRALIA

- Has thanked: 21 times

- Been thanked: 11 times

Re: Mugen BULLDOG mods.

Thanks for your suggestion Pierre. By chance might you have any images of what you are referring to? After studying my Tamiya 501X's drive train I realised the belt tensioners prevented the belt skipping on the approach side of the belt and pulley. Essentially I wanted to do something similar rather than just tension the belts at their middle. Whilst I could not quite fit my pulleys in as close as the 501's I did what I could to get the job done.This has worked well for both me and my pal 'Besty'. Both our Bulldogs had issues with belt slippage under load and braking whilst out on the race track. After this system was implemented on both of our cars we've not had any more issues.prp wrote:Hi Jason

Normally, you must put the belt tensioner under for the rear belt and on the belt for the front.

The belt force more on the belt tensioner on yours...

I do welcome any suggestions and I'm very keen to learn what other systems have and are being used.

I love modified Bulldogs

- prp

- Approved Member

- Posts: 665

- Joined: Sun Dec 10, 2006 4:27 pm

- Location: Lyon FRANCE

- Been thanked: 13 times

Re: Mugen BULLDOG mods.

Like on the K1 Schumacher, for the front belt the tensionner in on, and for the rear belt, he is under.

When your motor run the spur gear the front belt is tight on the under side, and the upper side is relax,

for the rear belt it's the opposite.

If you put the tensionner like you installed, the belt forced more on the tensionner.

Block the front diff with 1 hand, and turn the diff forward with the other hand and see the upper belt is relax.

On the 501X the ball bearing are directly on the pulley and you have in more excentric to tight the belt.

I see on mine too , the center diff pulley are not round...

- Bormac

- Approved Member

- Posts: 3113

- Joined: Wed Sep 05, 2007 3:52 pm

- Location: CENTRAL COAST, NSW AUSTRALIA

- Has thanked: 21 times

- Been thanked: 11 times

Re: Mugen BULLDOG mods.

I get what you mean now Pierre. The belt feeds onto the pulley straight rather then under load from a tensioning bearing. Ofcourse I am no expert on this kind of stuff but I located my tensioner bearings at those locations because I thought that would prevent any slack from the belt going onto the pulley.

If someone else wants to try Pierre's concept out on their Bulldog I'd very much like to see how that goes aswell.

If someone else wants to try Pierre's concept out on their Bulldog I'd very much like to see how that goes aswell.

Create an account or sign in to join the discussion

You need to be a member in order to post a reply

Create an account

Not a member? register to join our community

Members can start their own topics & subscribe to topics

It’s free and only takes a minute

Sign in

-

- Similar Topics

- Replies

- Views

- Last post

-

- 2 Replies

- 2699 Views

-

Last post by urban hype

-

- 2 Replies

- 2084 Views

-

Last post by saga101

-

- 10 Replies

- 2479 Views

-

Last post by HotRodJosh

-

- 13 Replies

- 3070 Views

-

Last post by BattleTrak

-

- 9 Replies

- 2239 Views

-

Last post by Mr. ED

-

- 52 Replies

- 11936 Views

-

Last post by Mr. ED

-

- 12 Replies

- 2175 Views

-

Last post by Bormac

-

- 1 Replies

- 1273 Views

-

Last post by shodog

Who is online

Users browsing this forum: No registered users and 2 guests