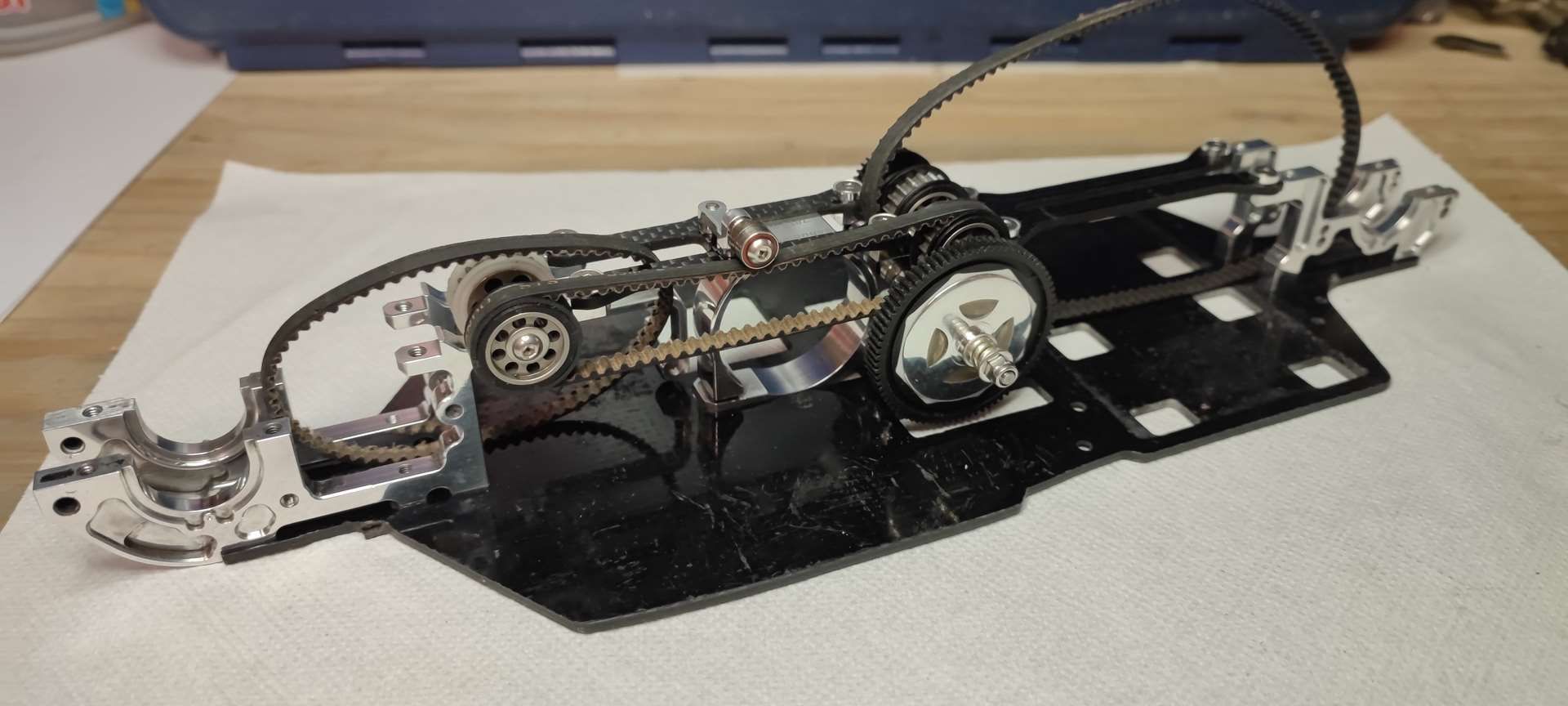

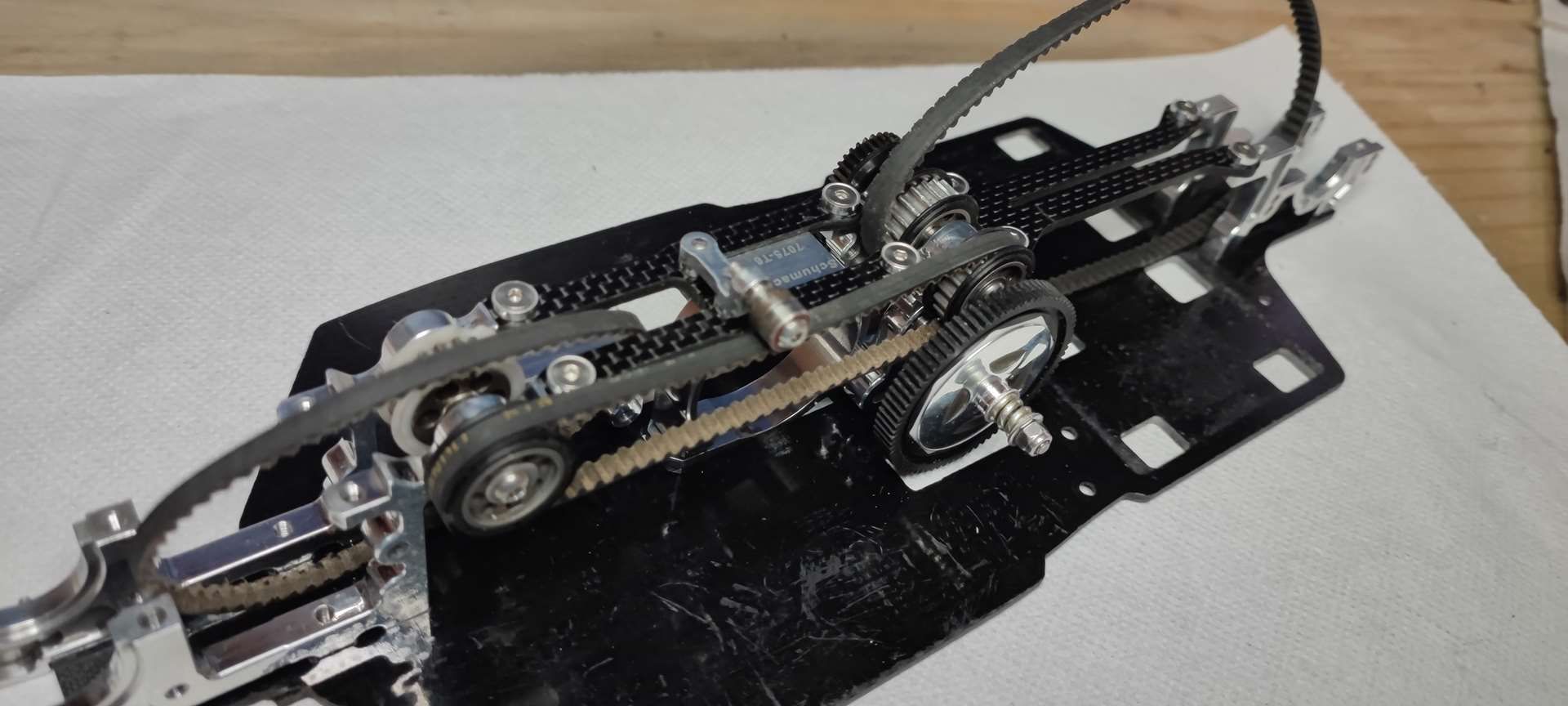

Here is the topic dedicated to the restoration of my Cat SX3.

This one was acquired during an exchange with a member of another forum about 1 year ago. For lack of time and especially lack of desire, I had not looked into it.

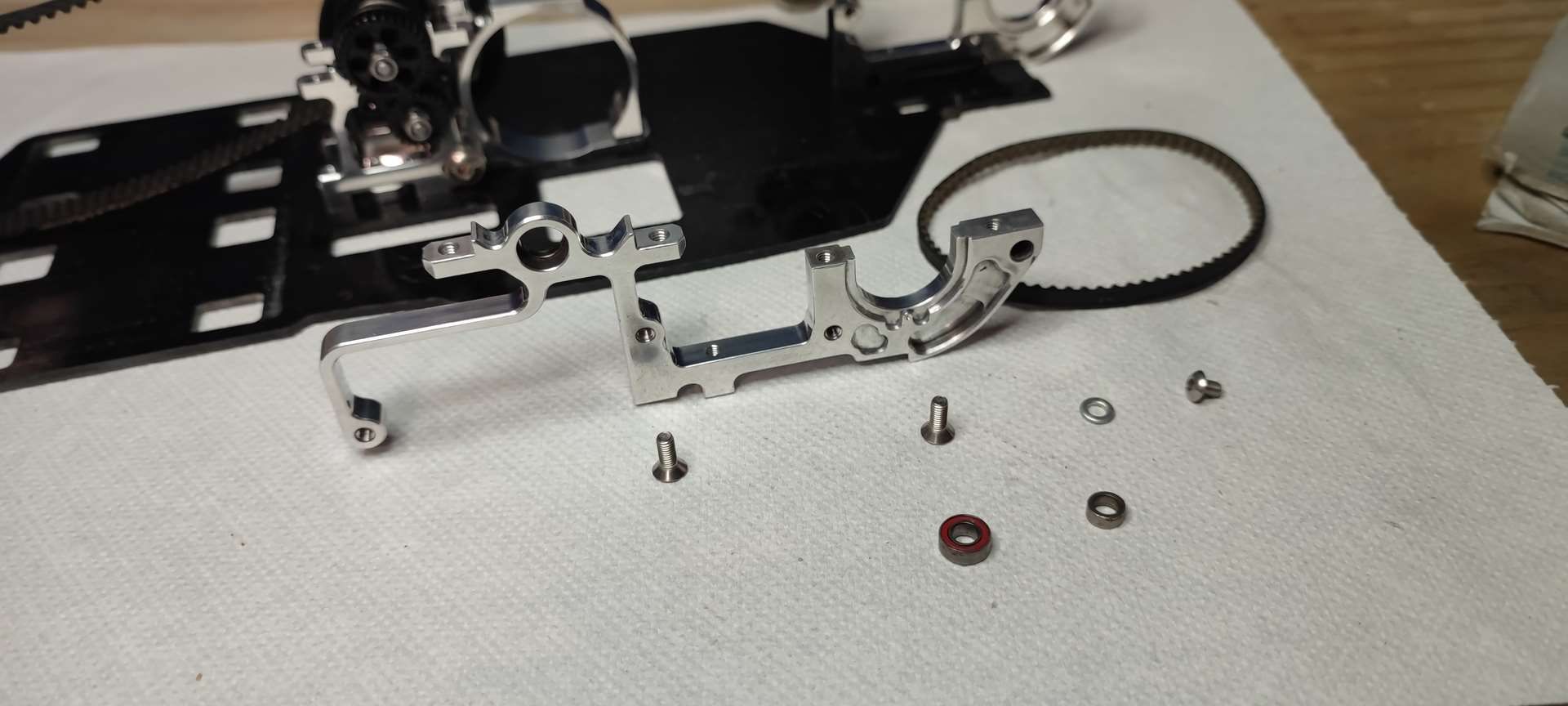

It will therefore be subject to a reshaping in my own way, with complete deanodization of the aluminum parts and new screws in A2 stainless steel.

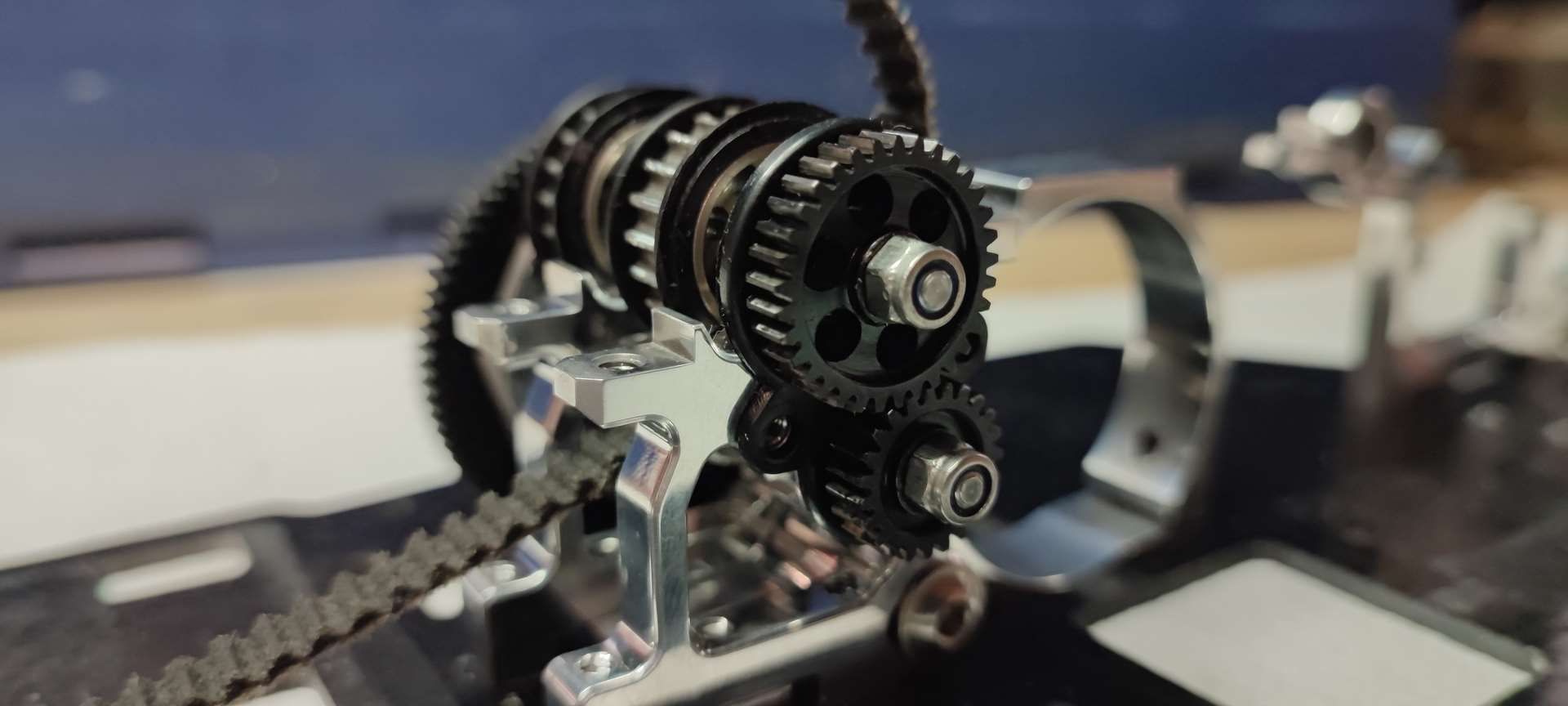

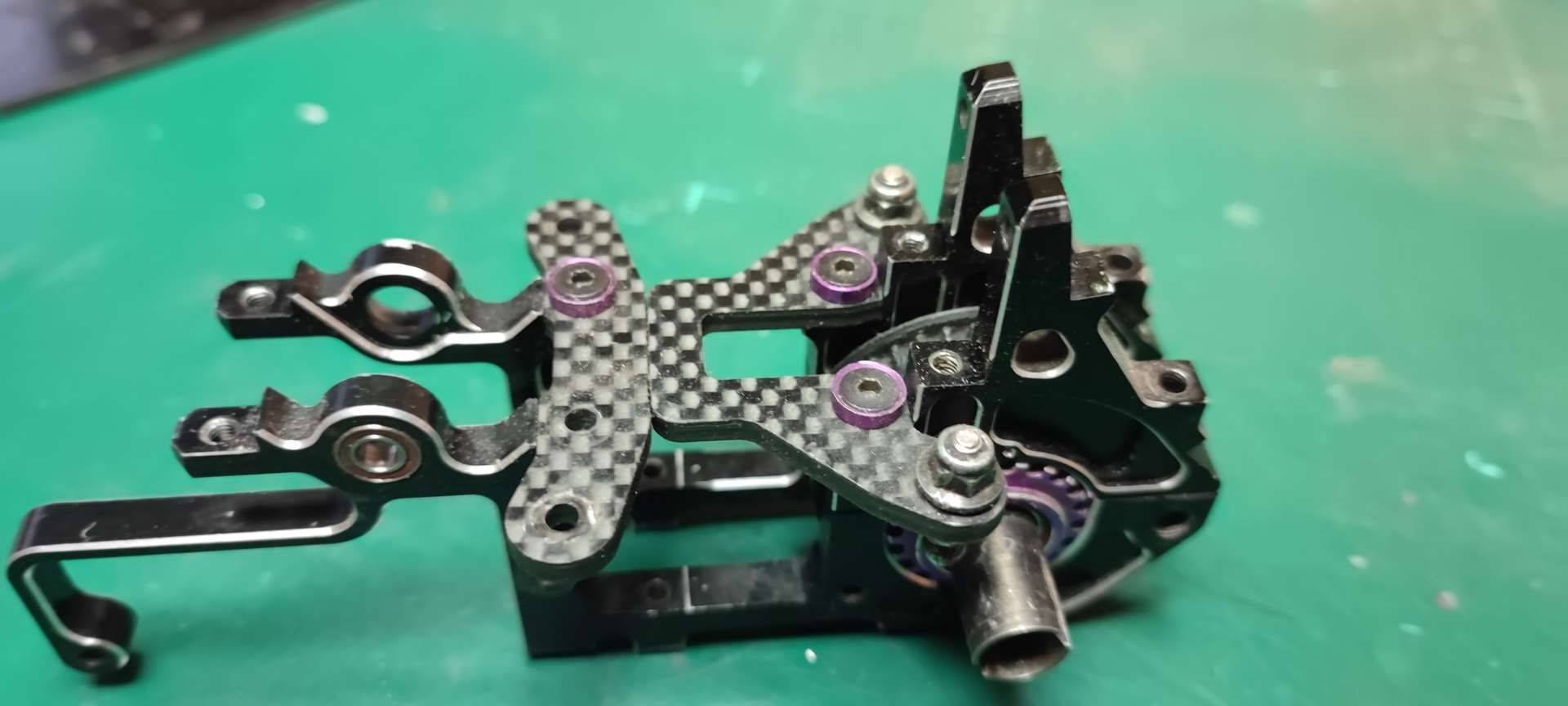

When dismantling, I came across a multitude of bad surprises...

So here is his story that started last Sunday

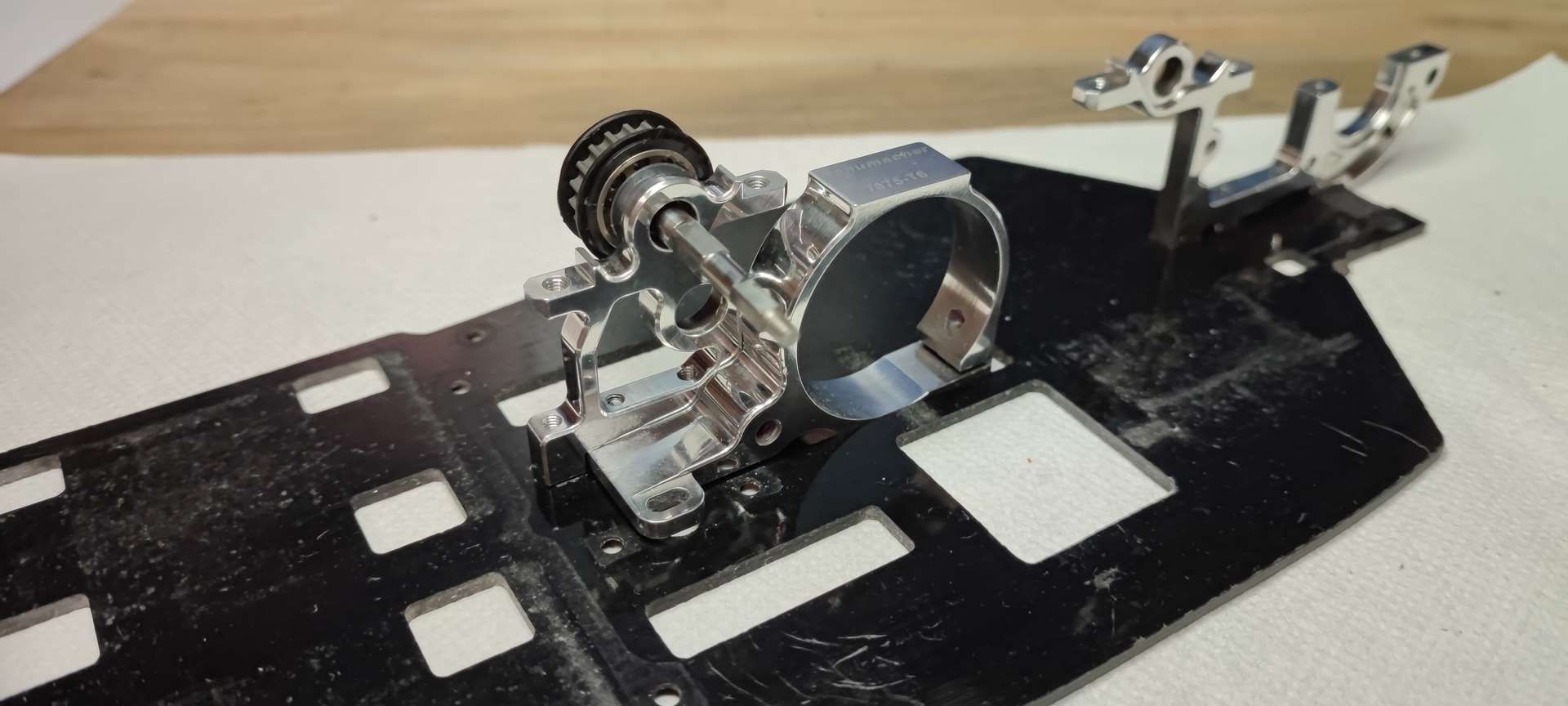

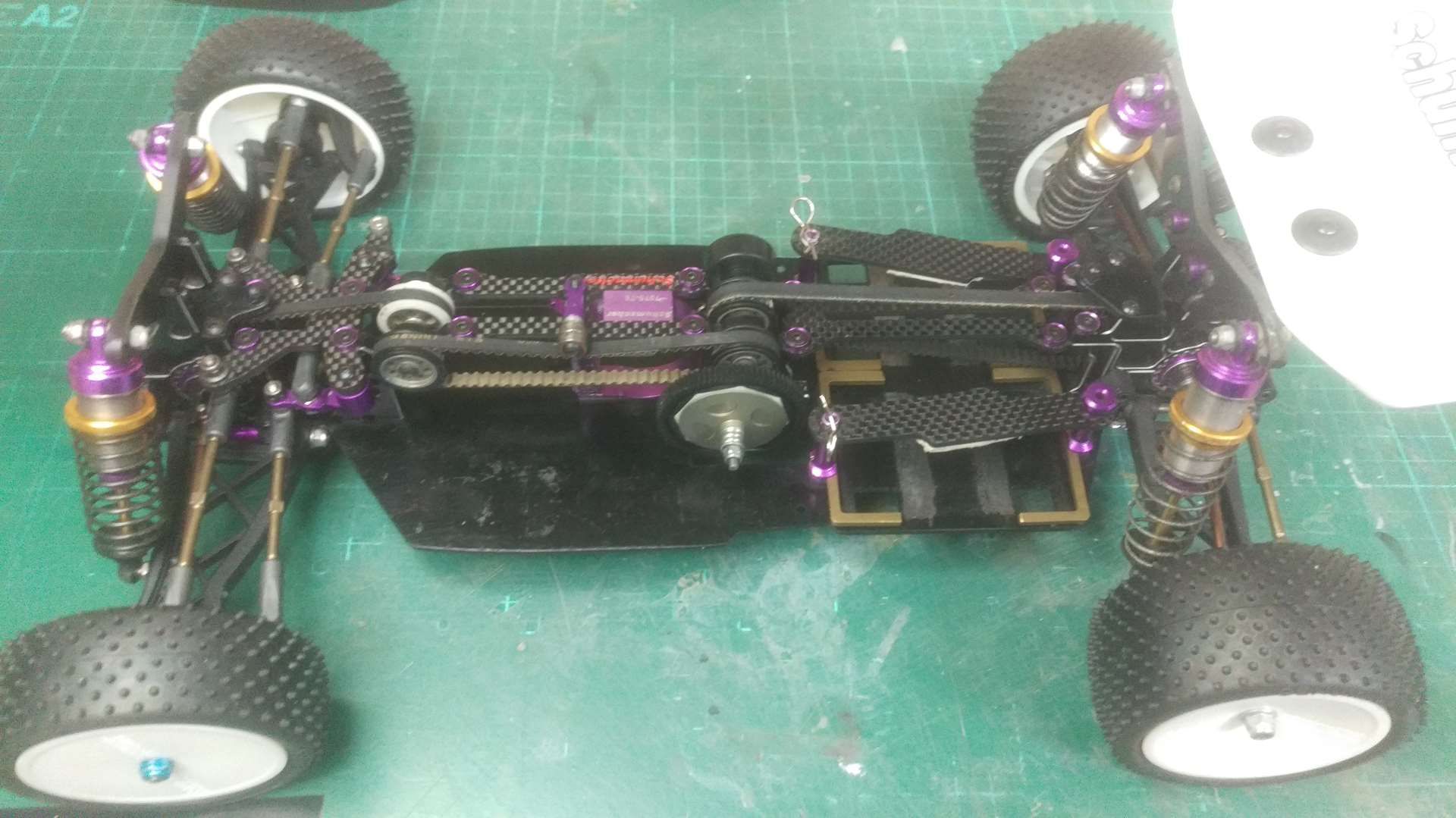

Here it is when it arrives:

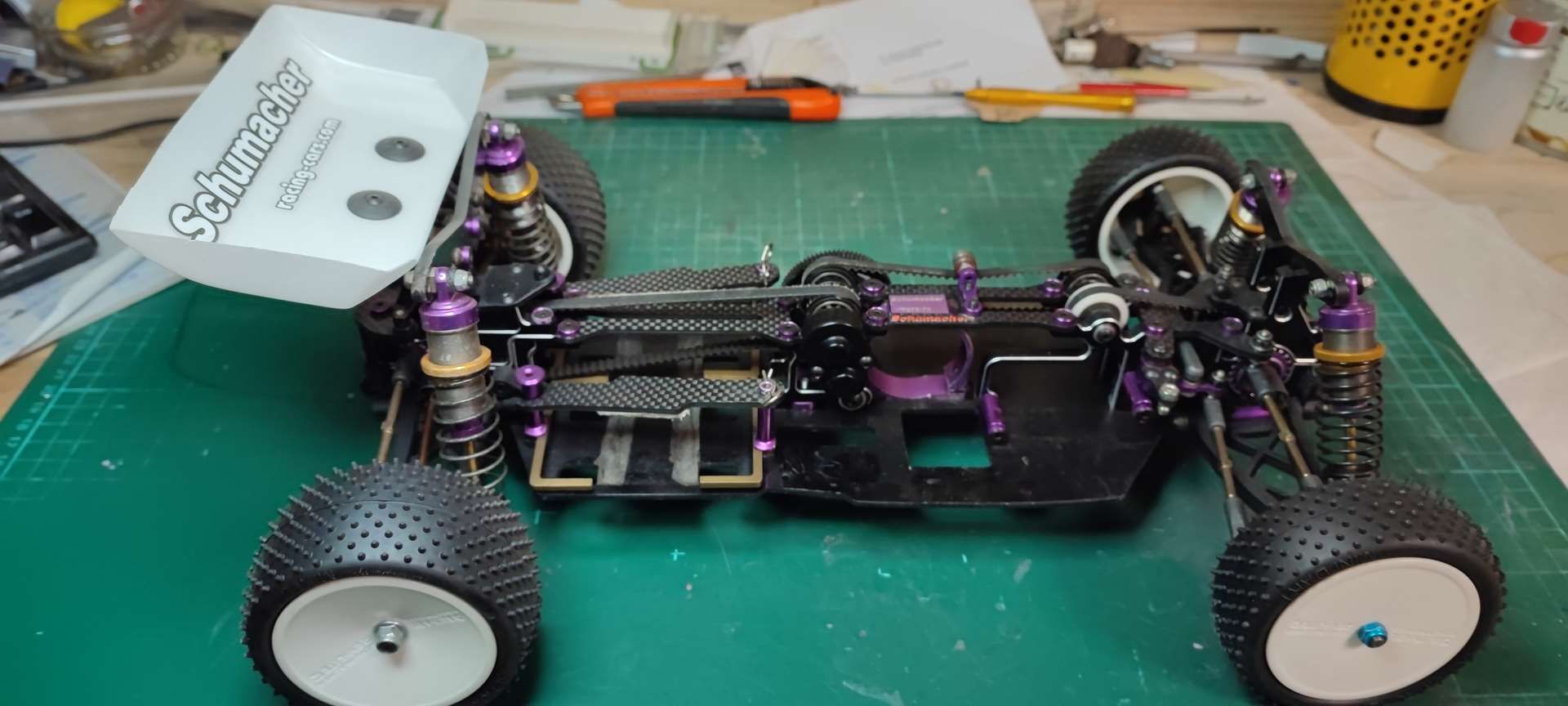

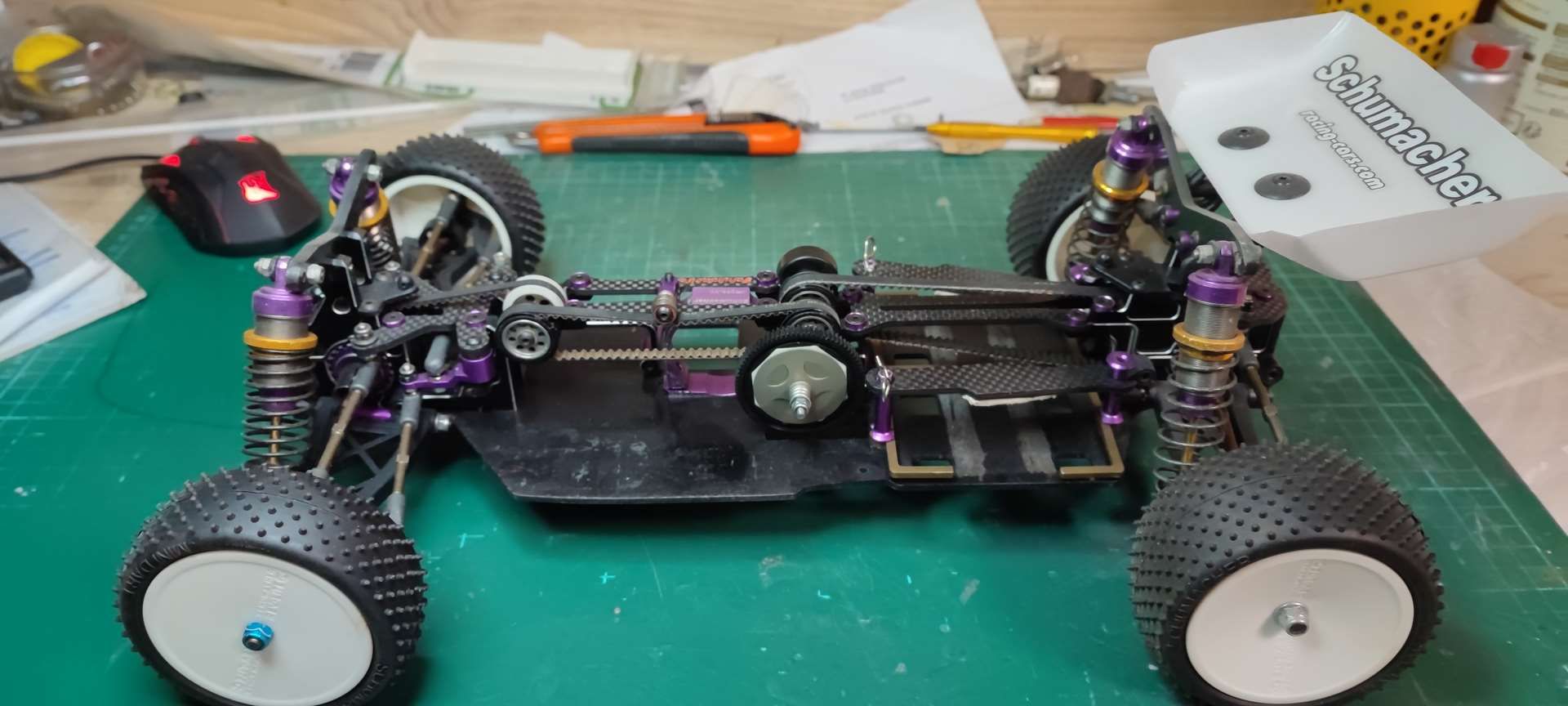

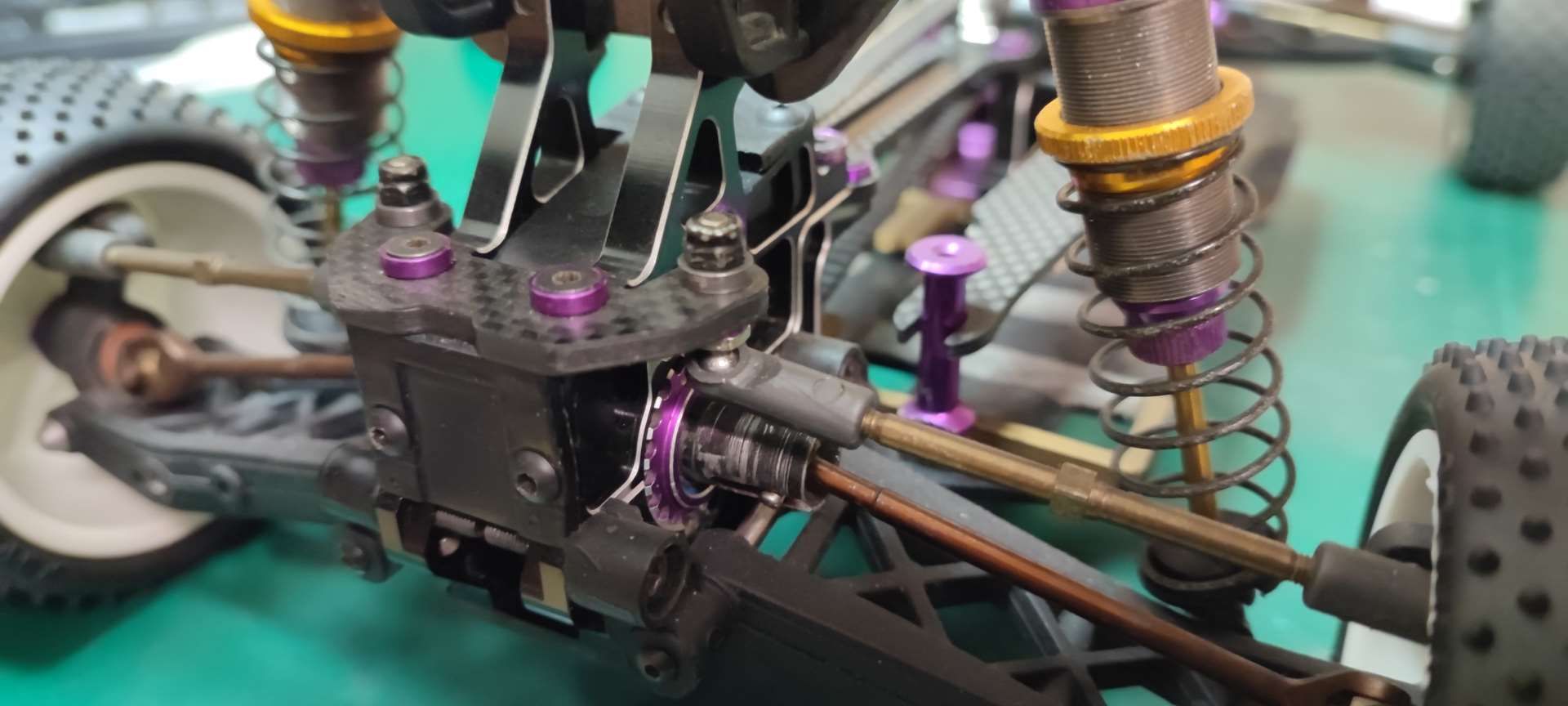

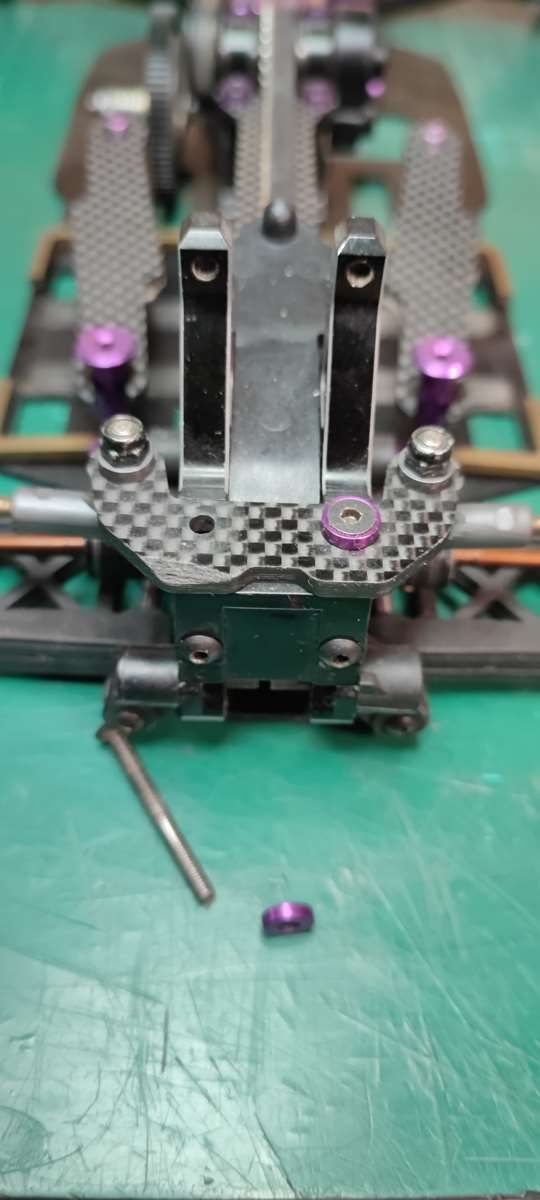

Here it is today before its disassembly:

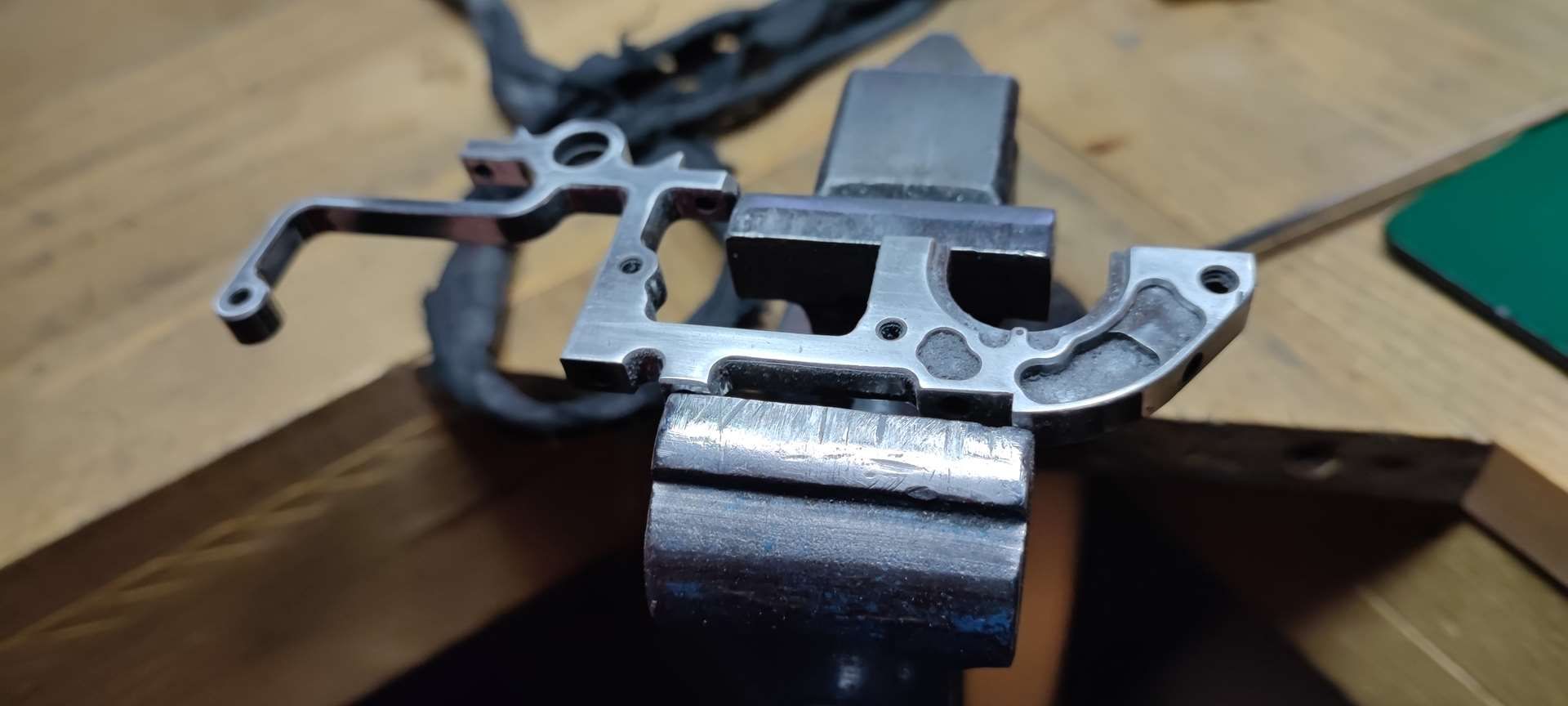

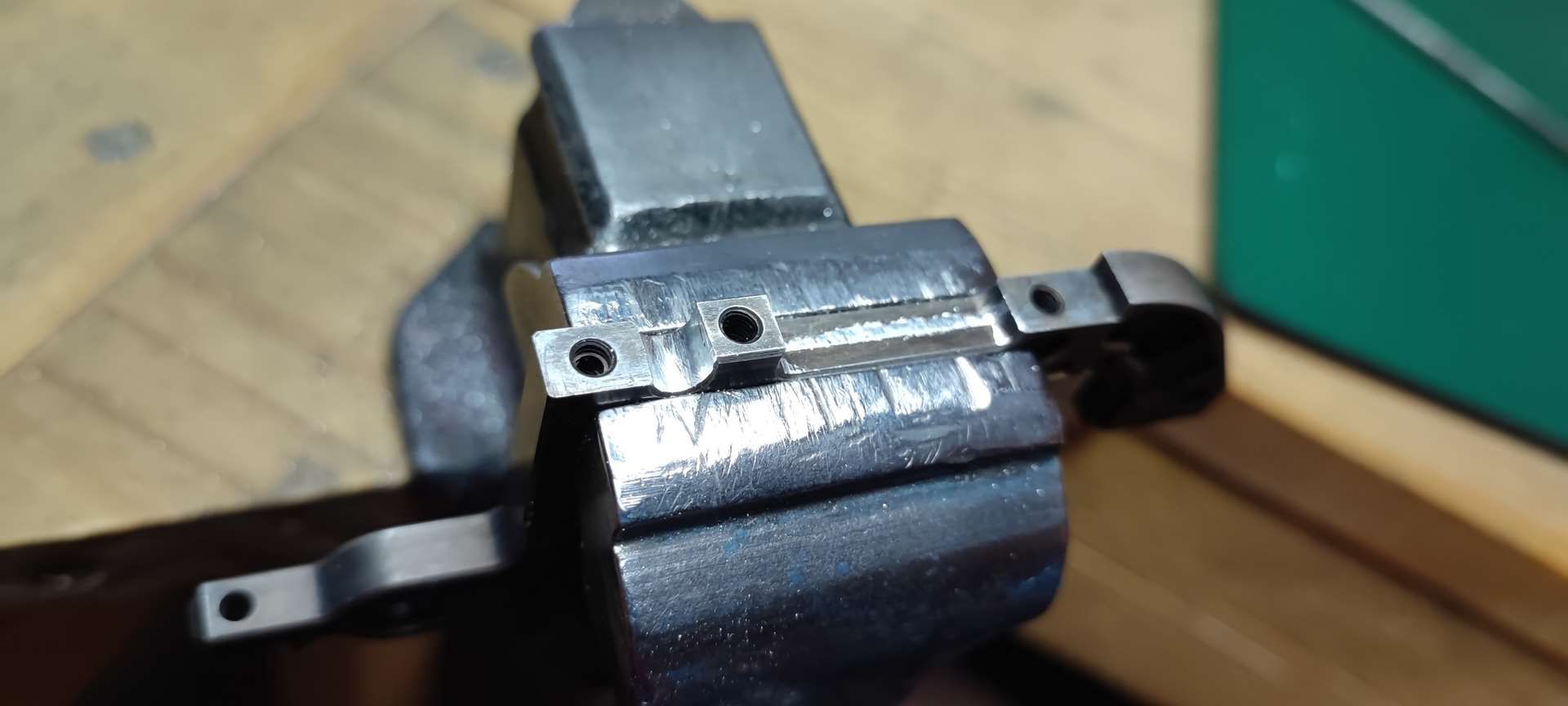

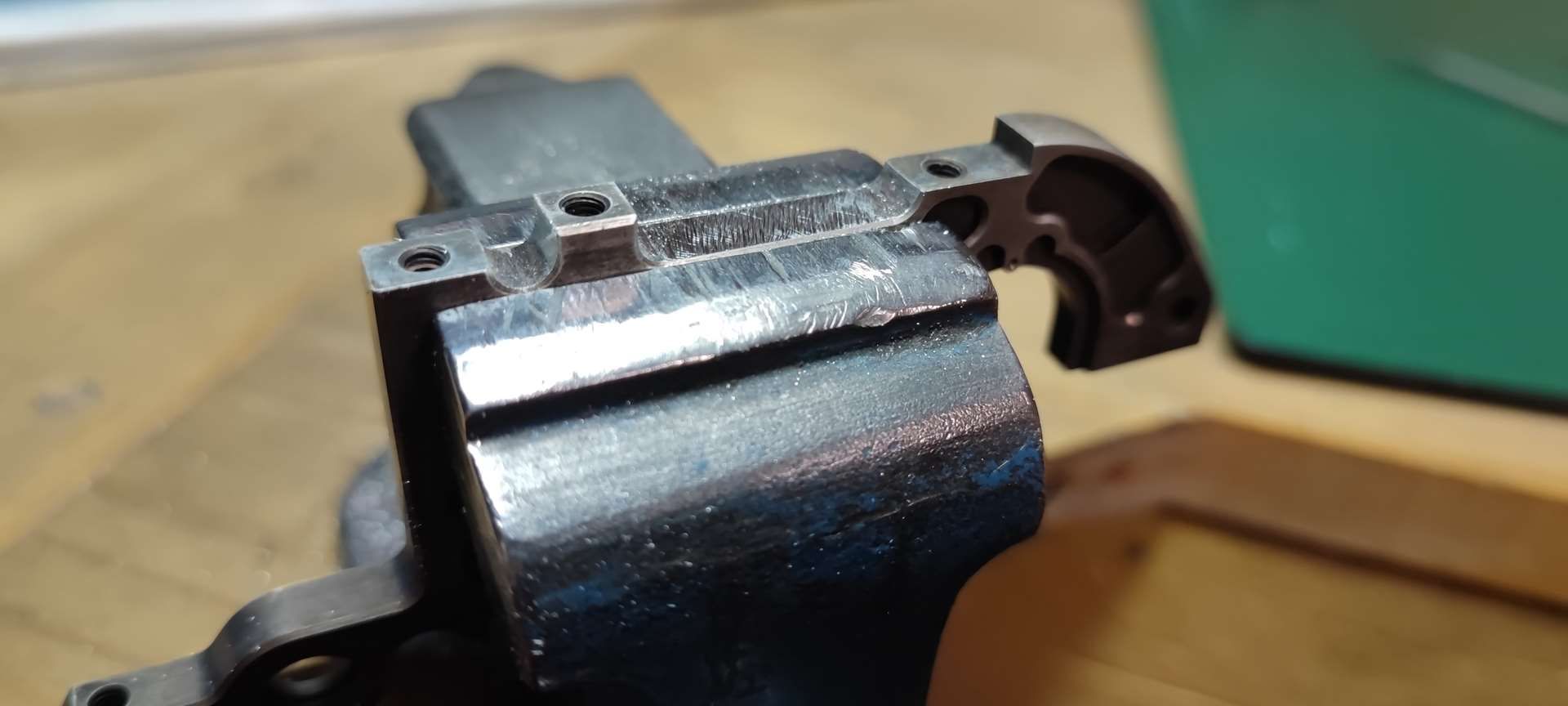

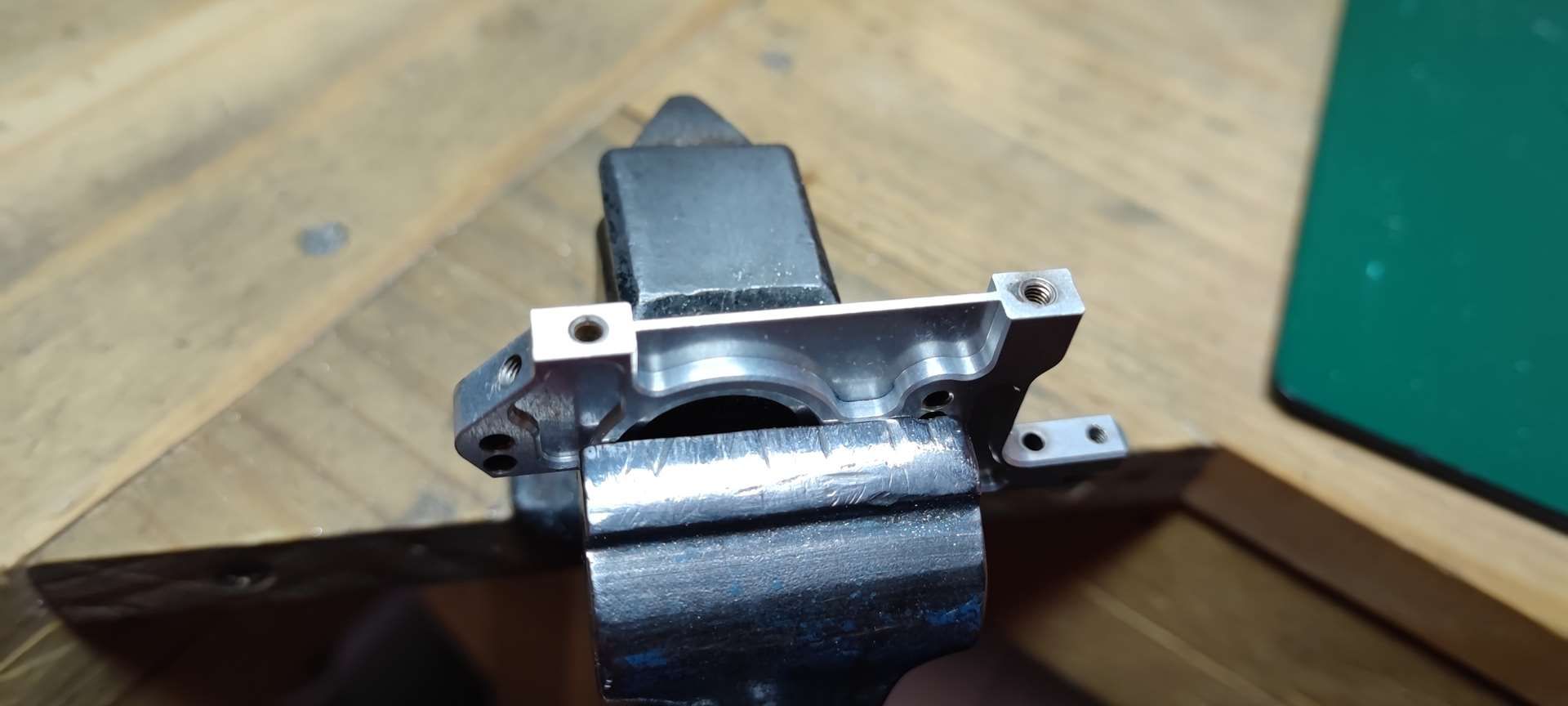

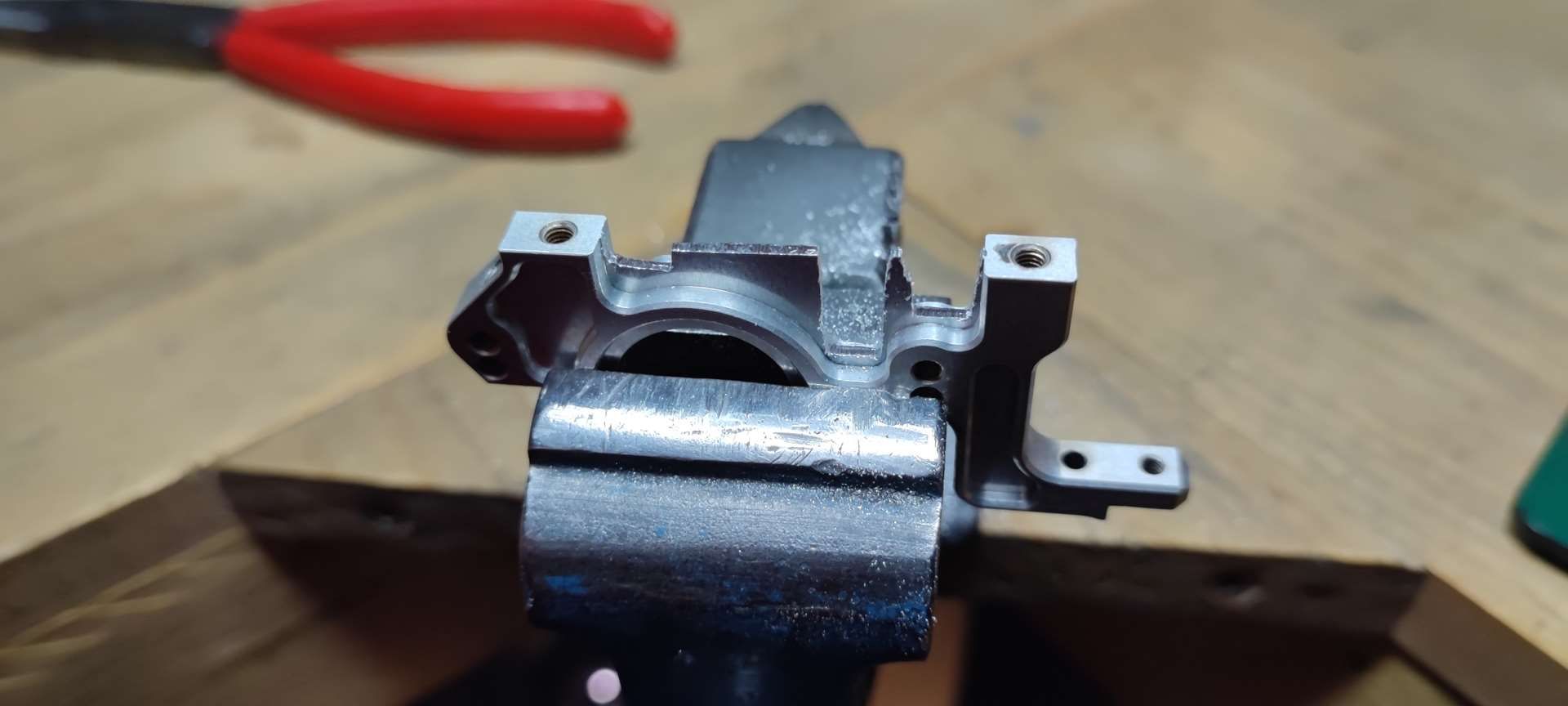

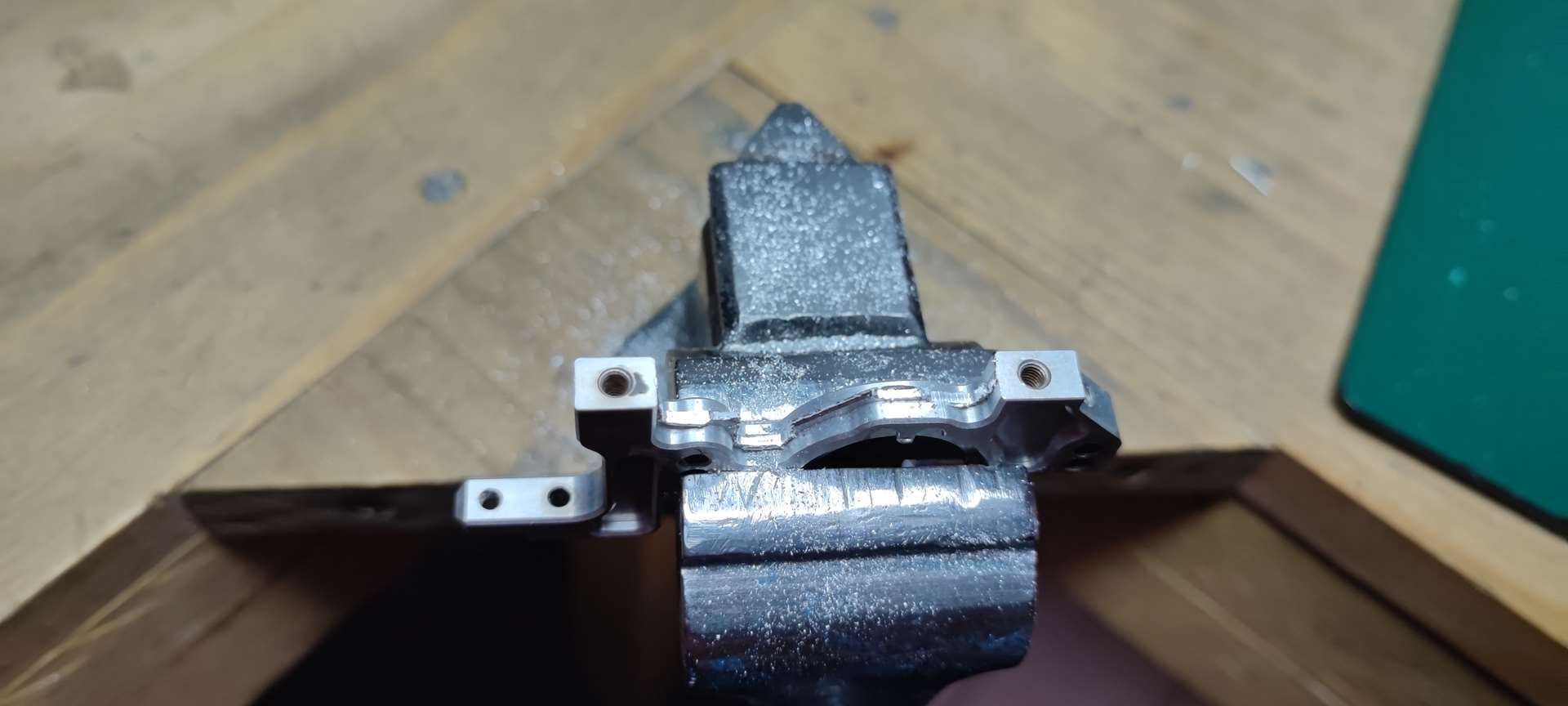

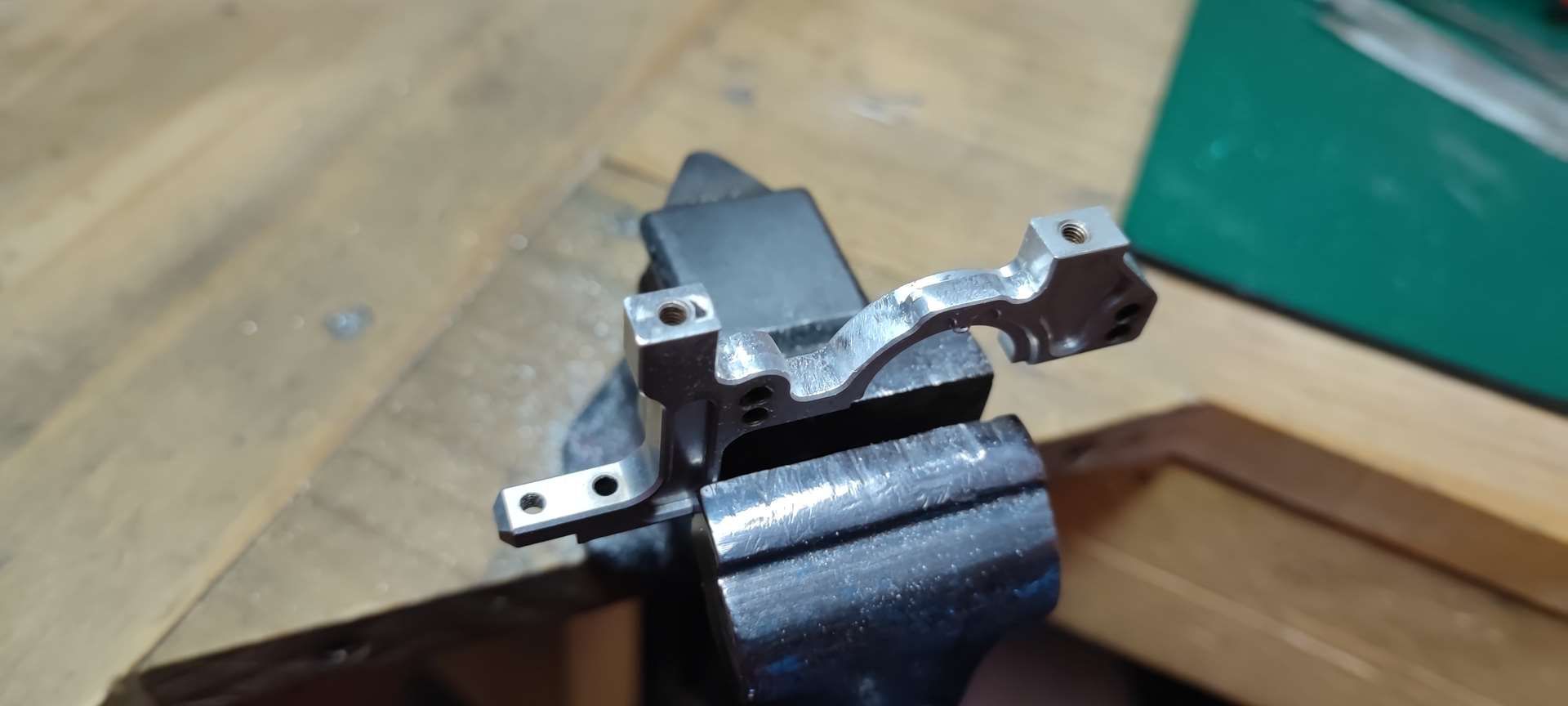

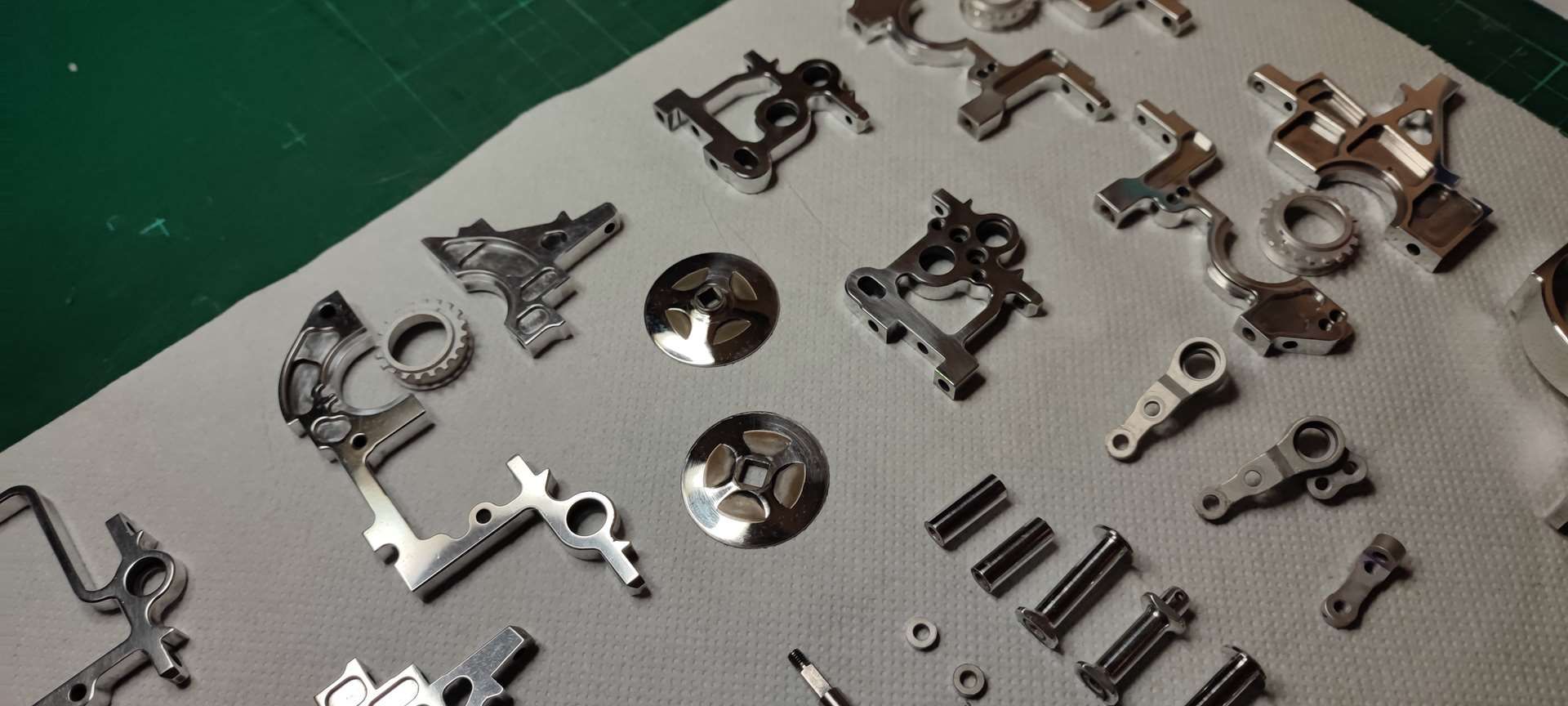

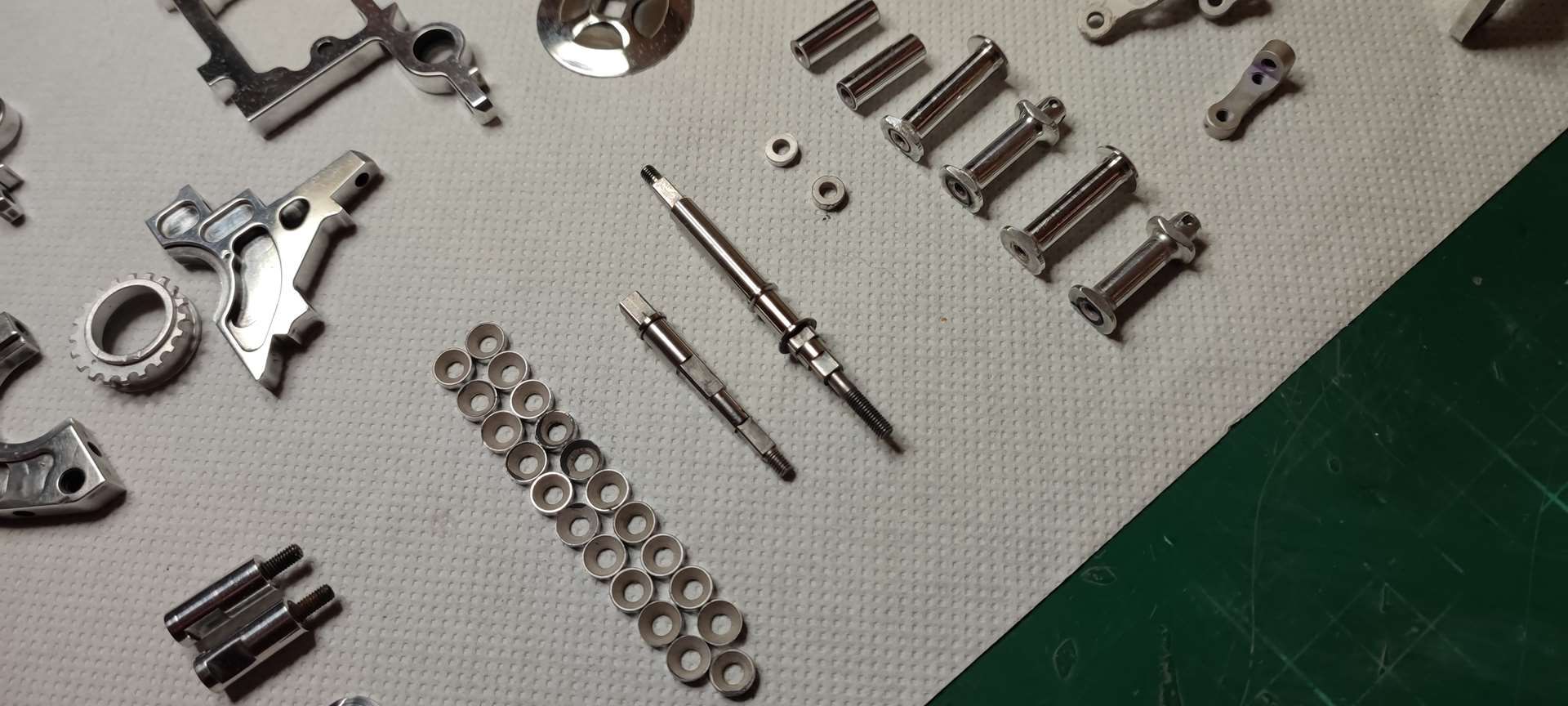

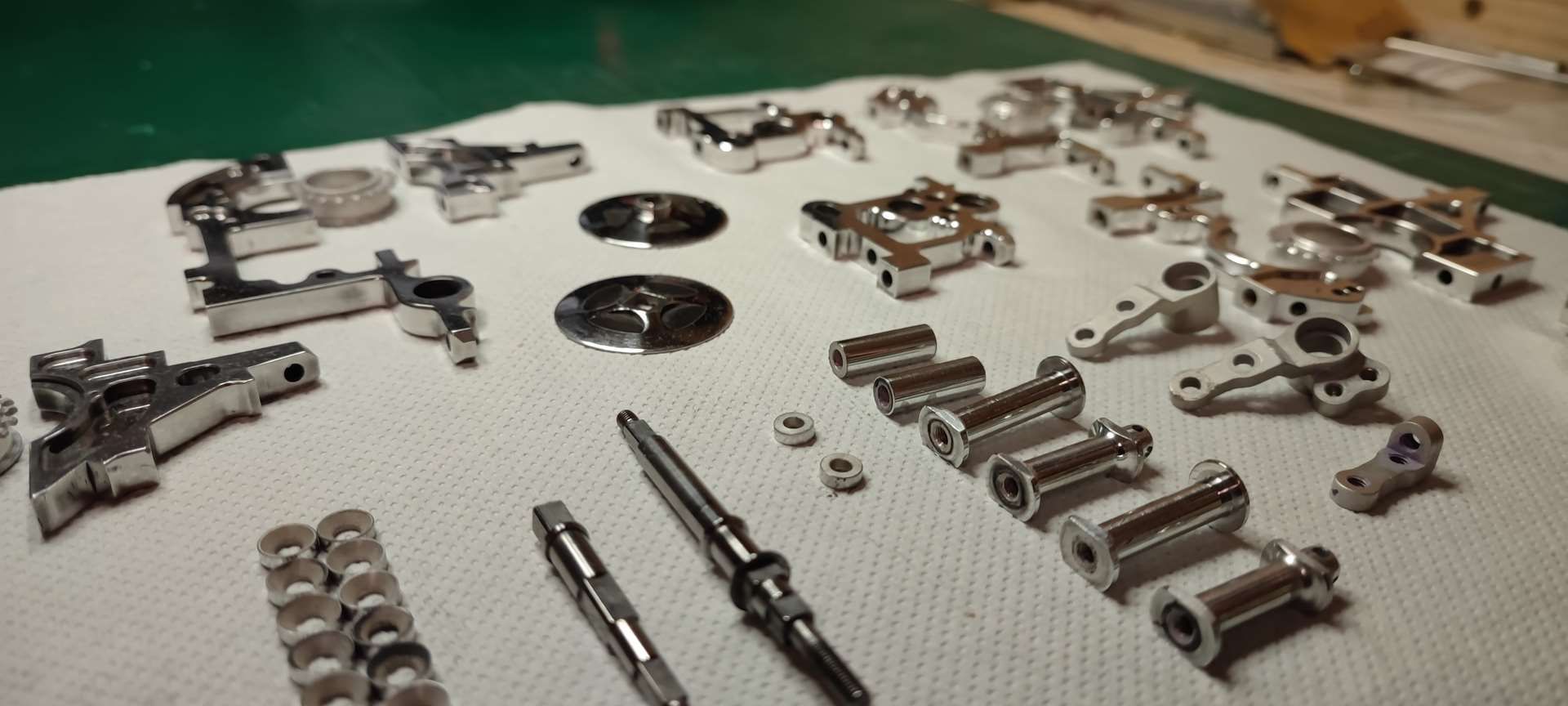

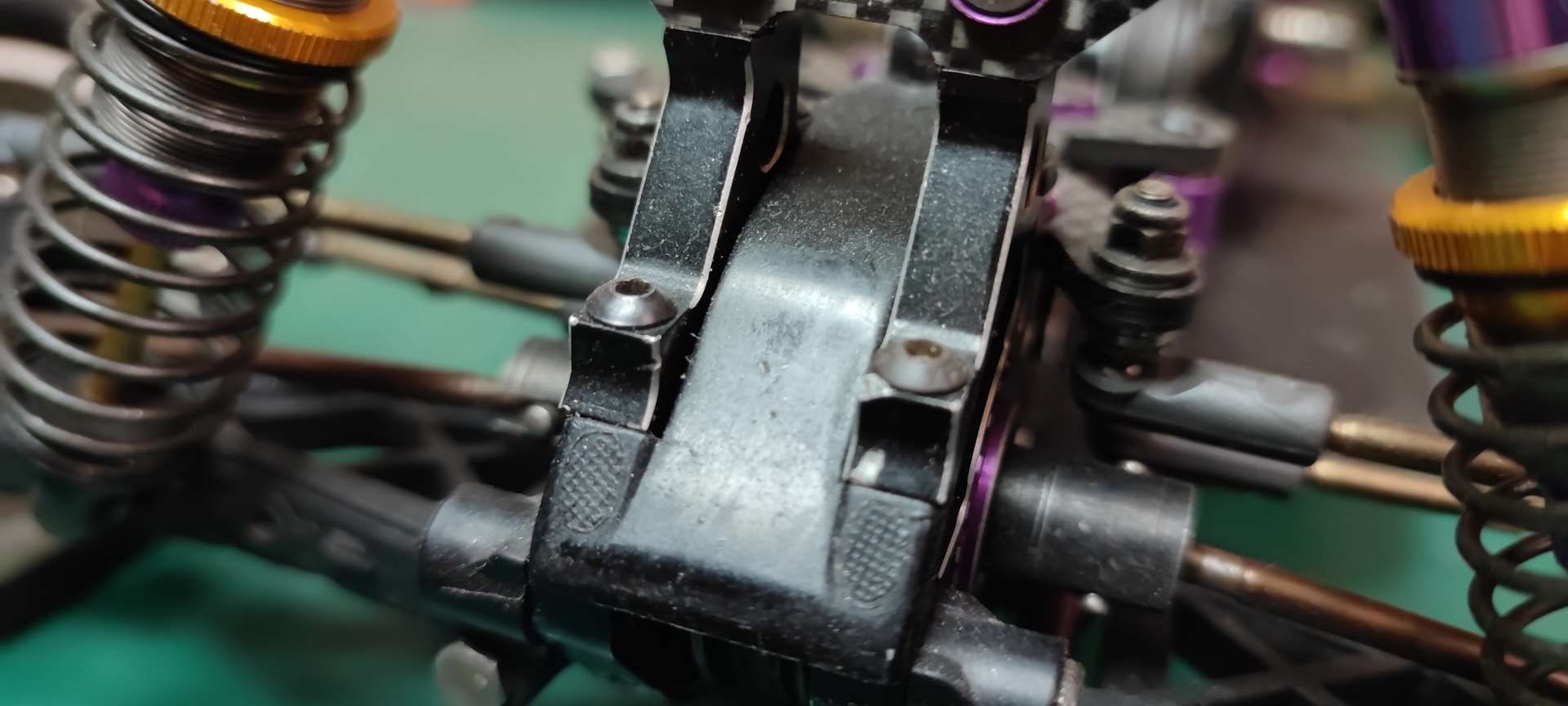

A multitude of shocks and scratches on many aluminum parts (I'm not talking about non-compliant screws here and there):

I'm going to have to clean, sand and untwist, then do some threading again...

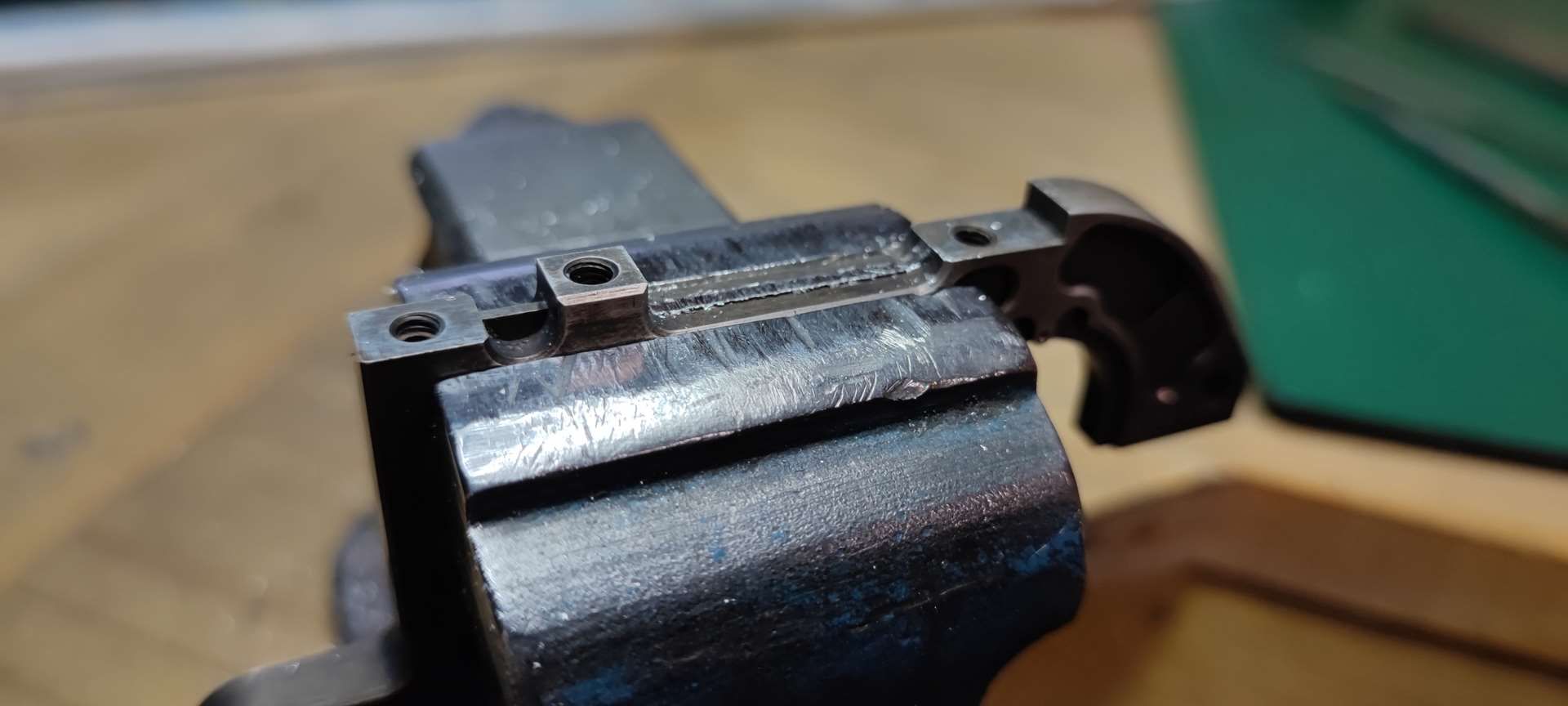

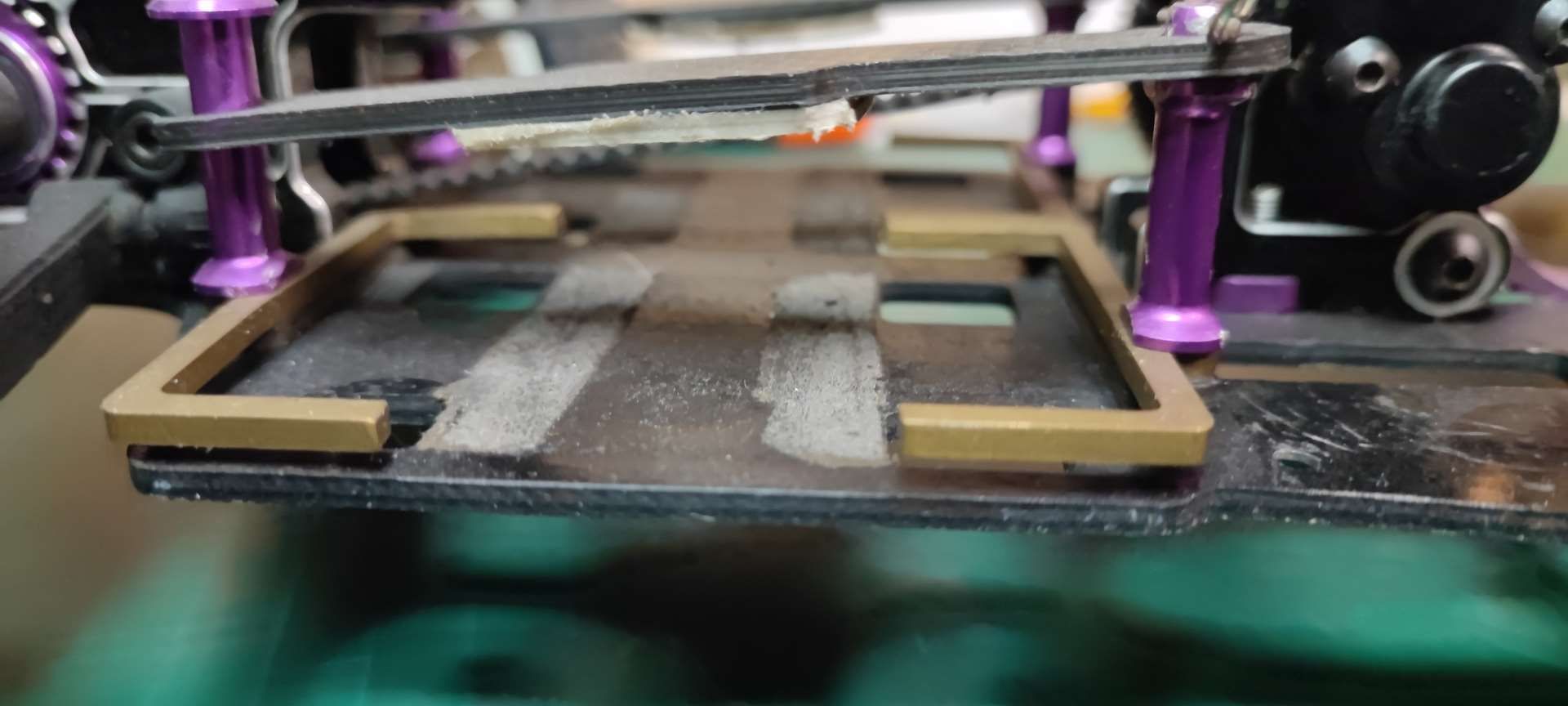

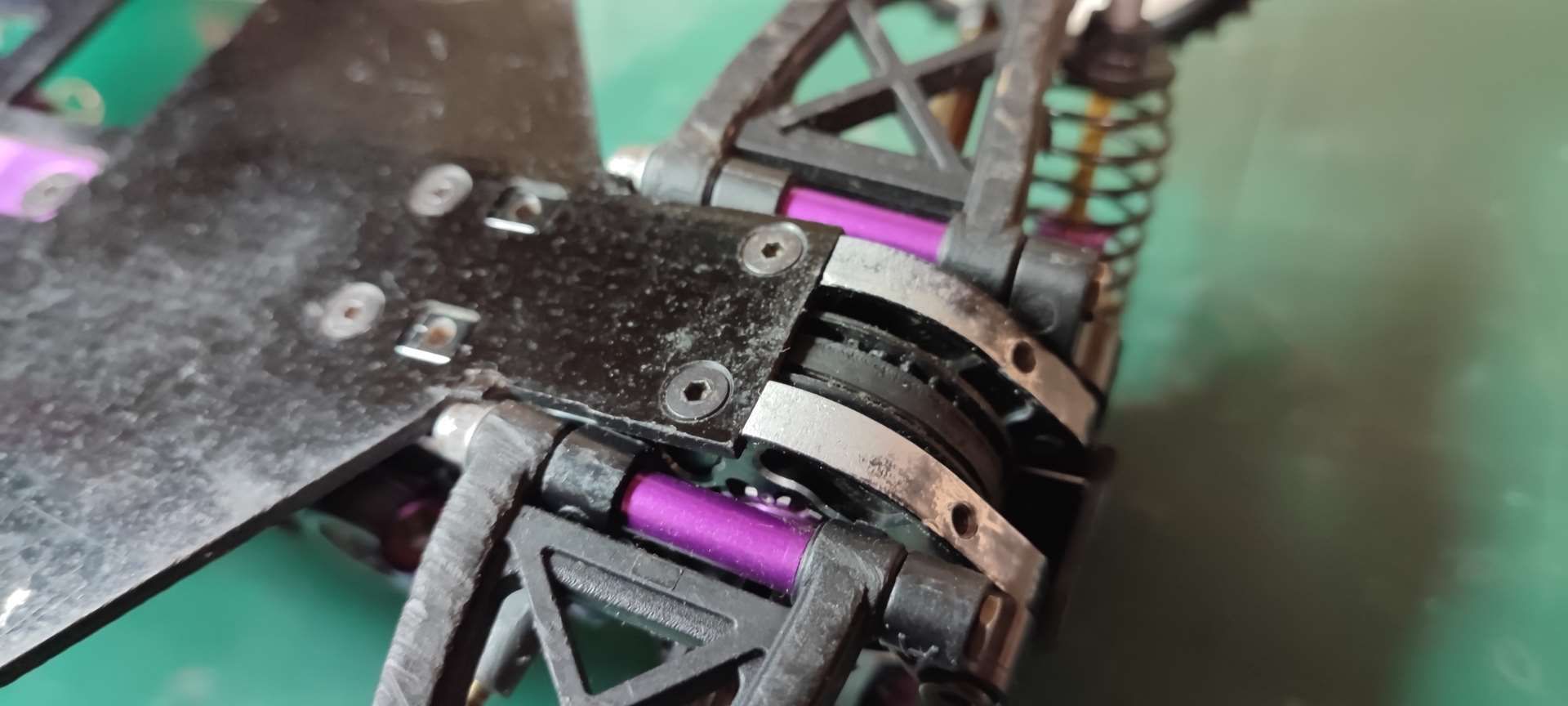

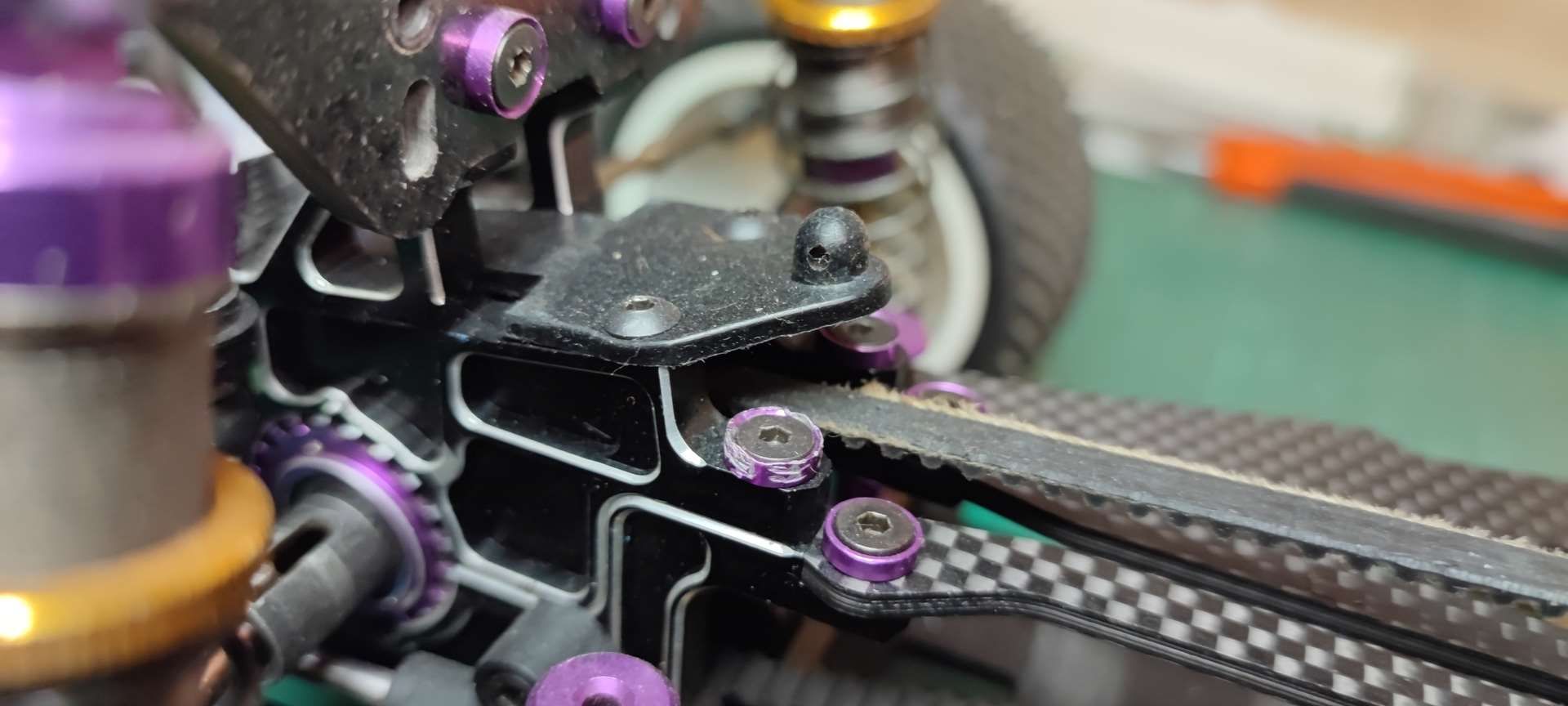

A stripped thread and the broken carbon plate:

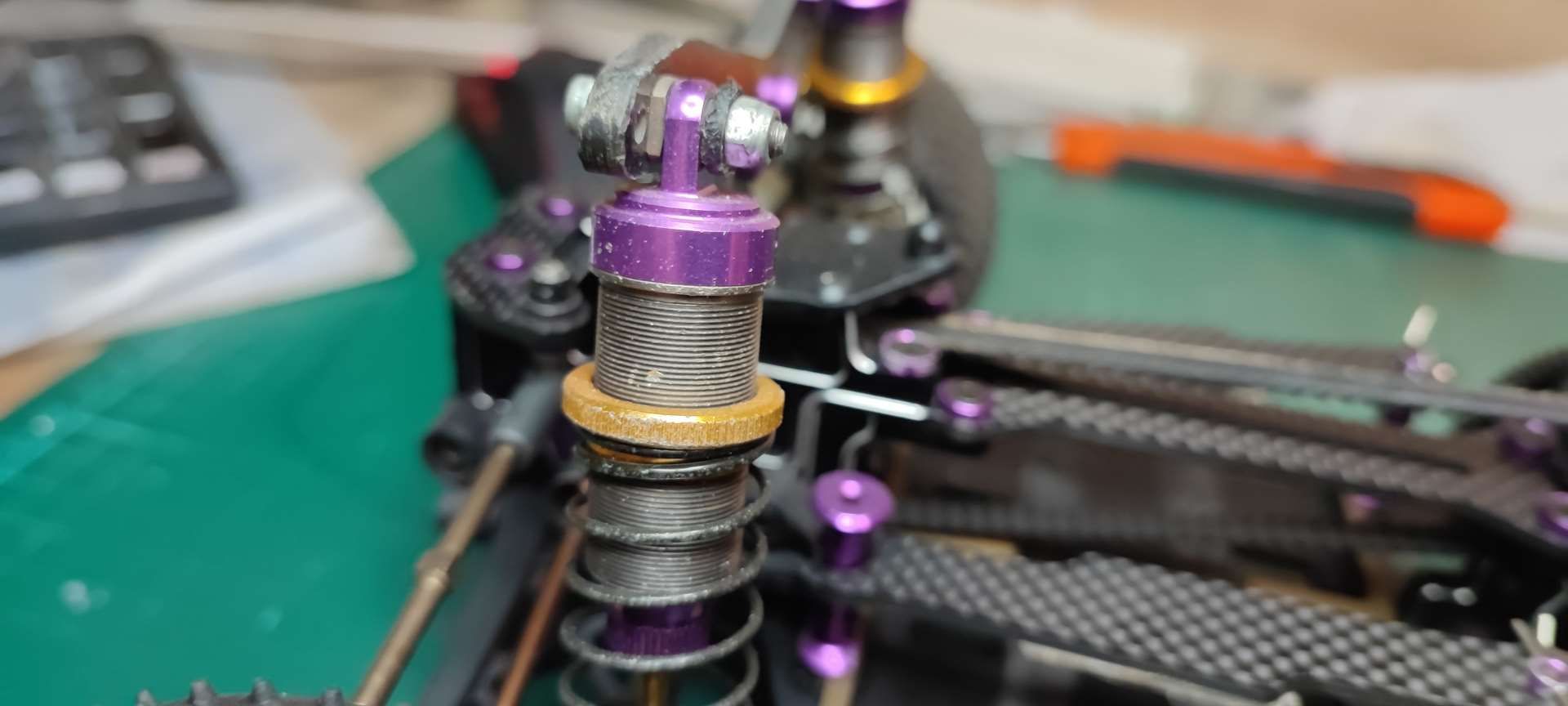

A jammed screw:

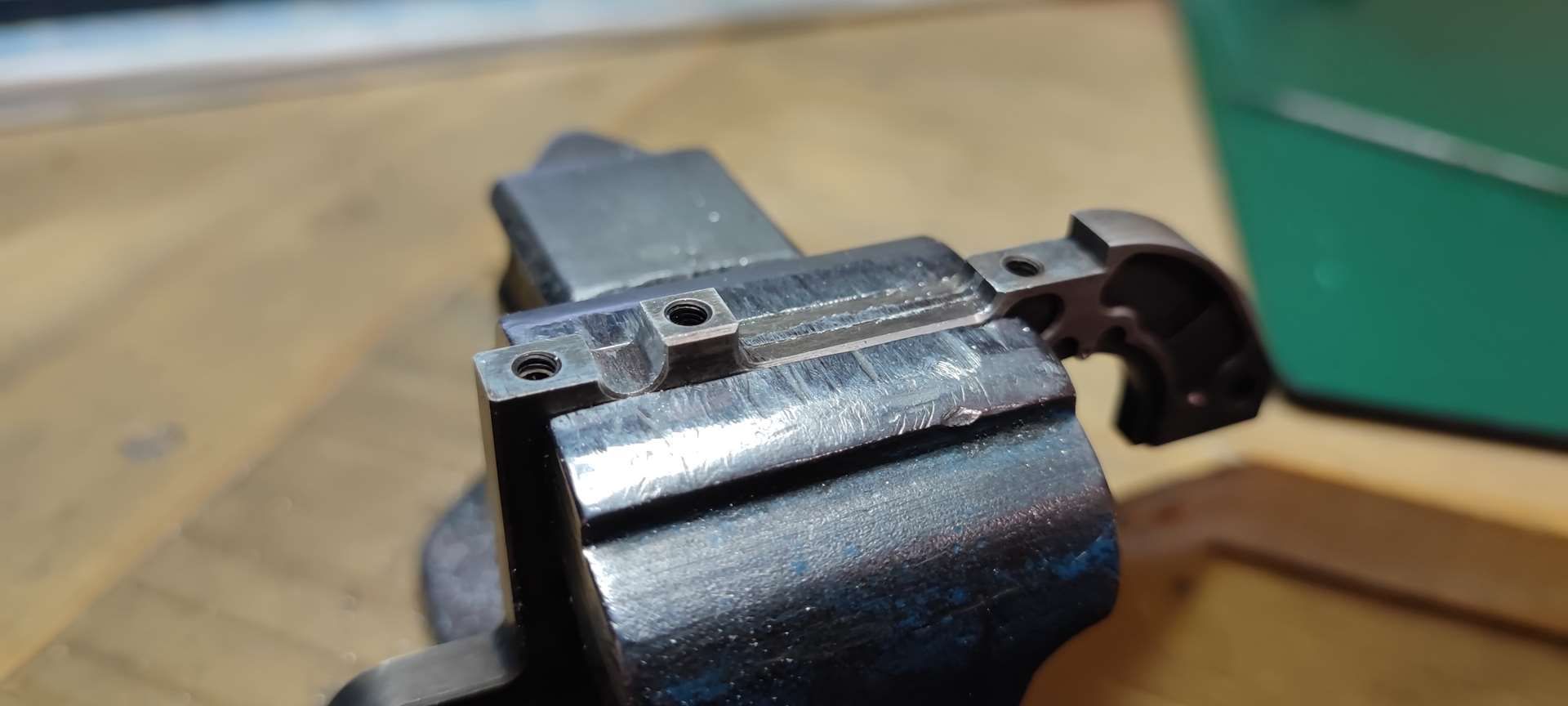

Rear carbon plate broken... he had to pick up this poor chassis:

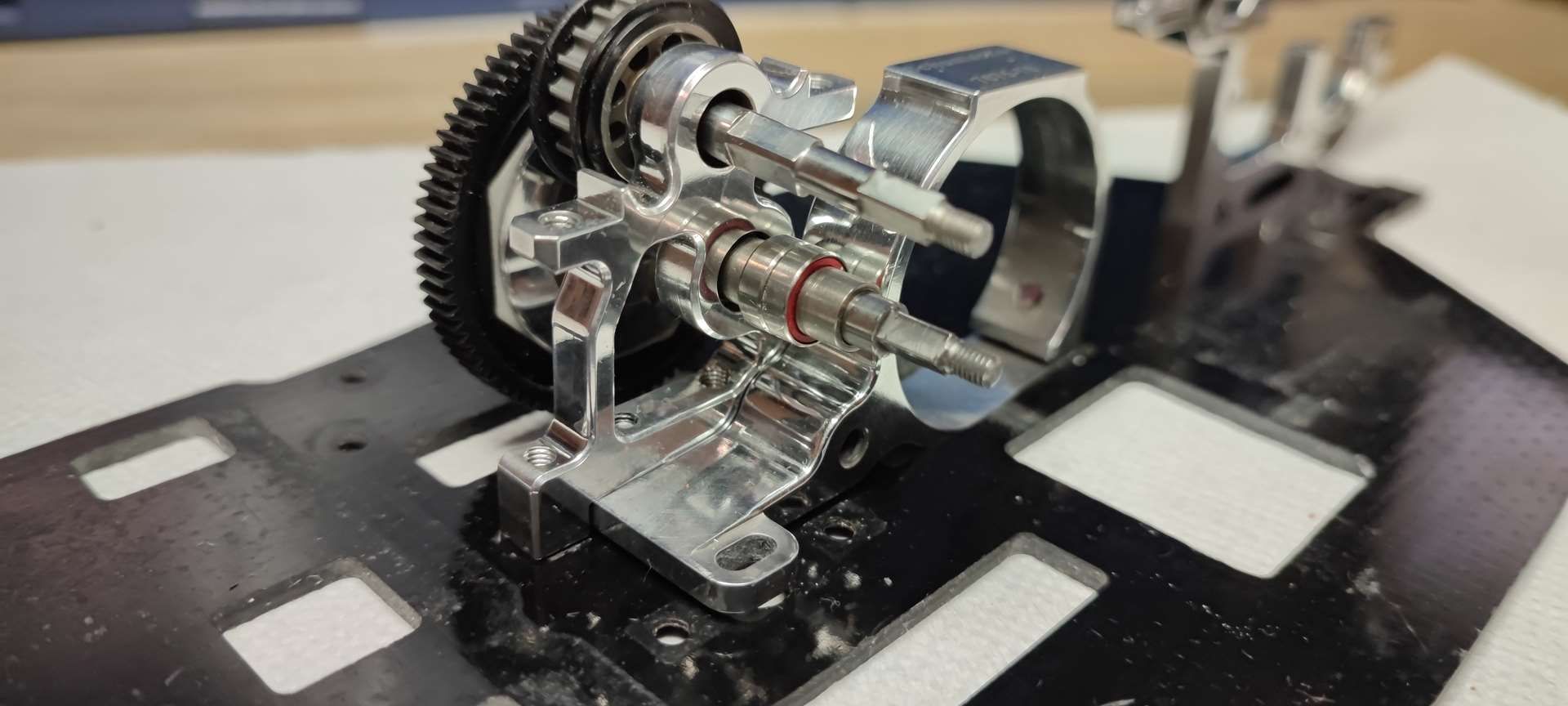

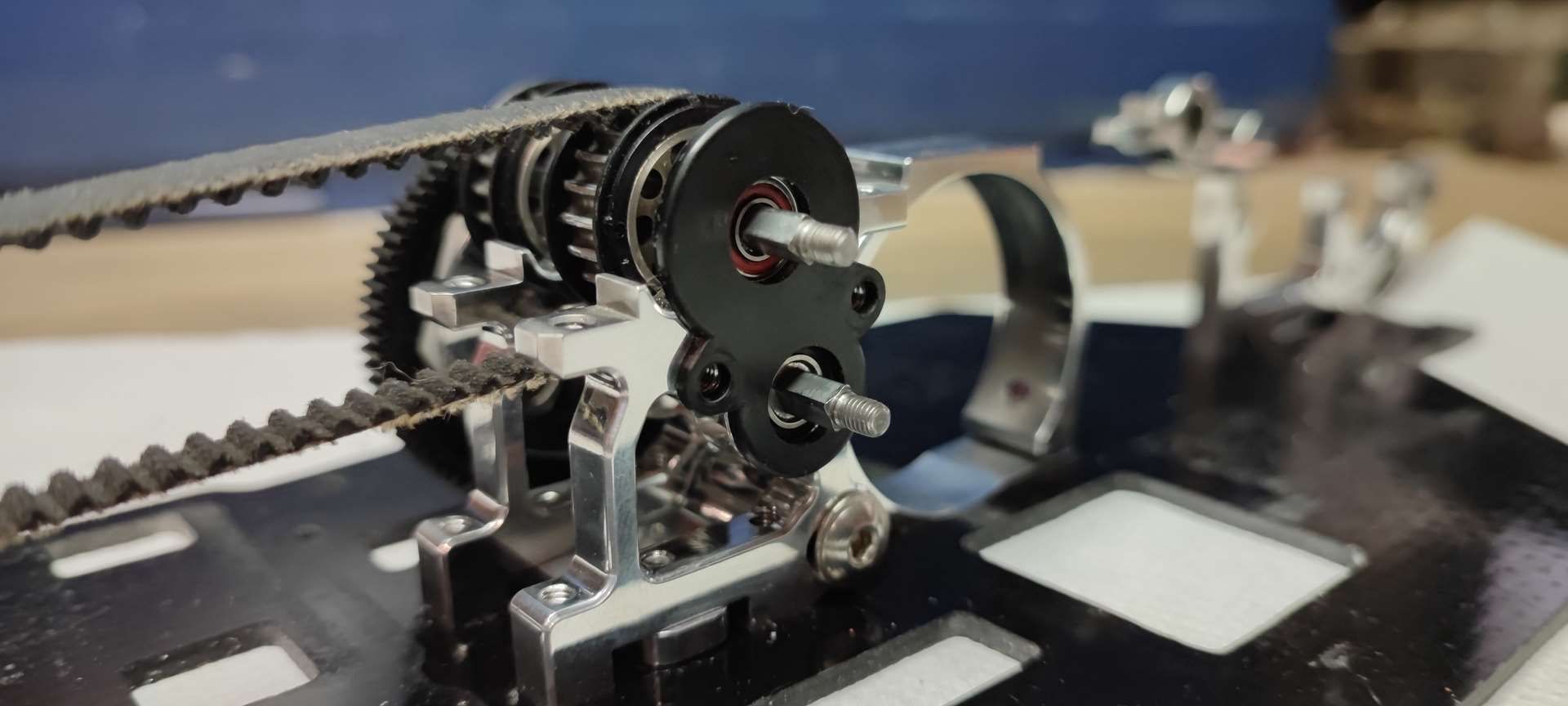

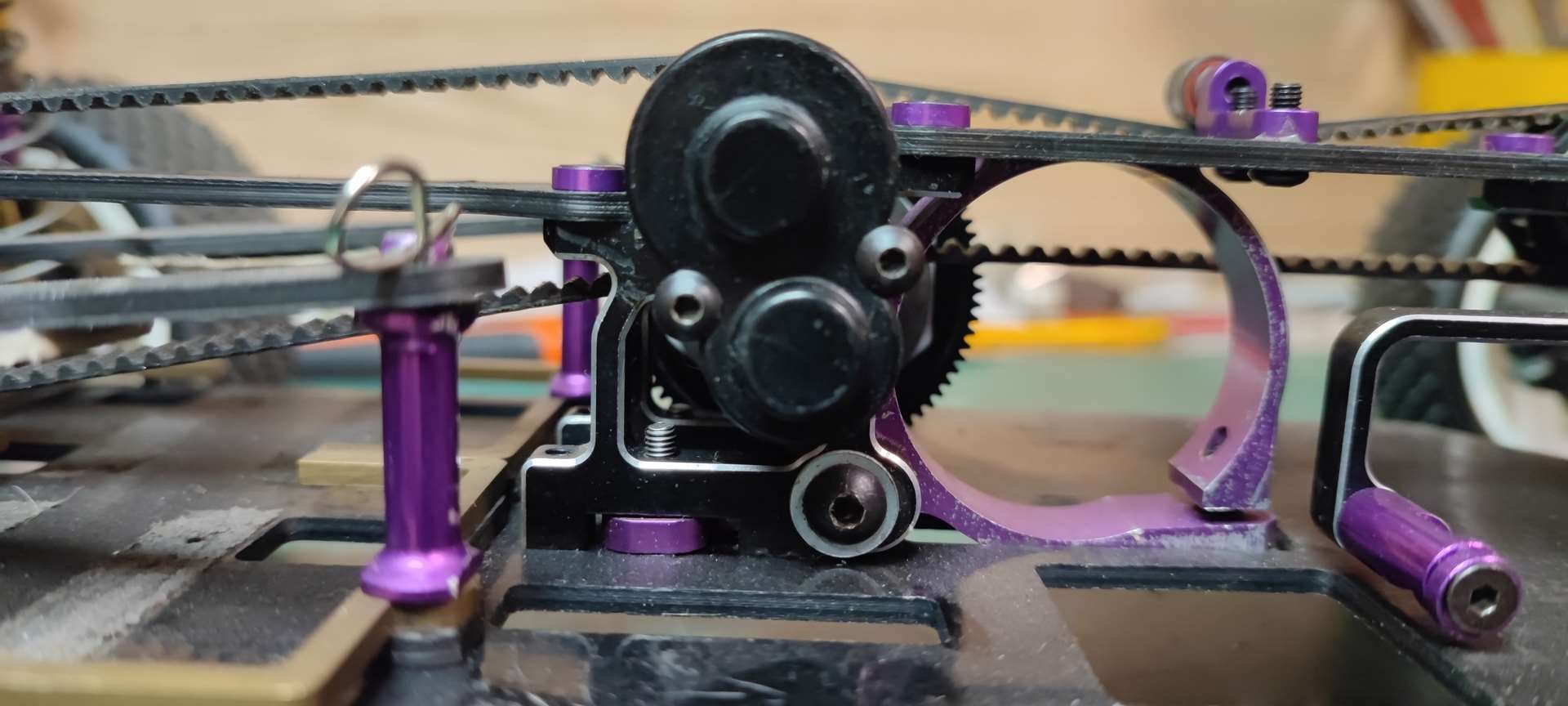

Broken rear diff flange:

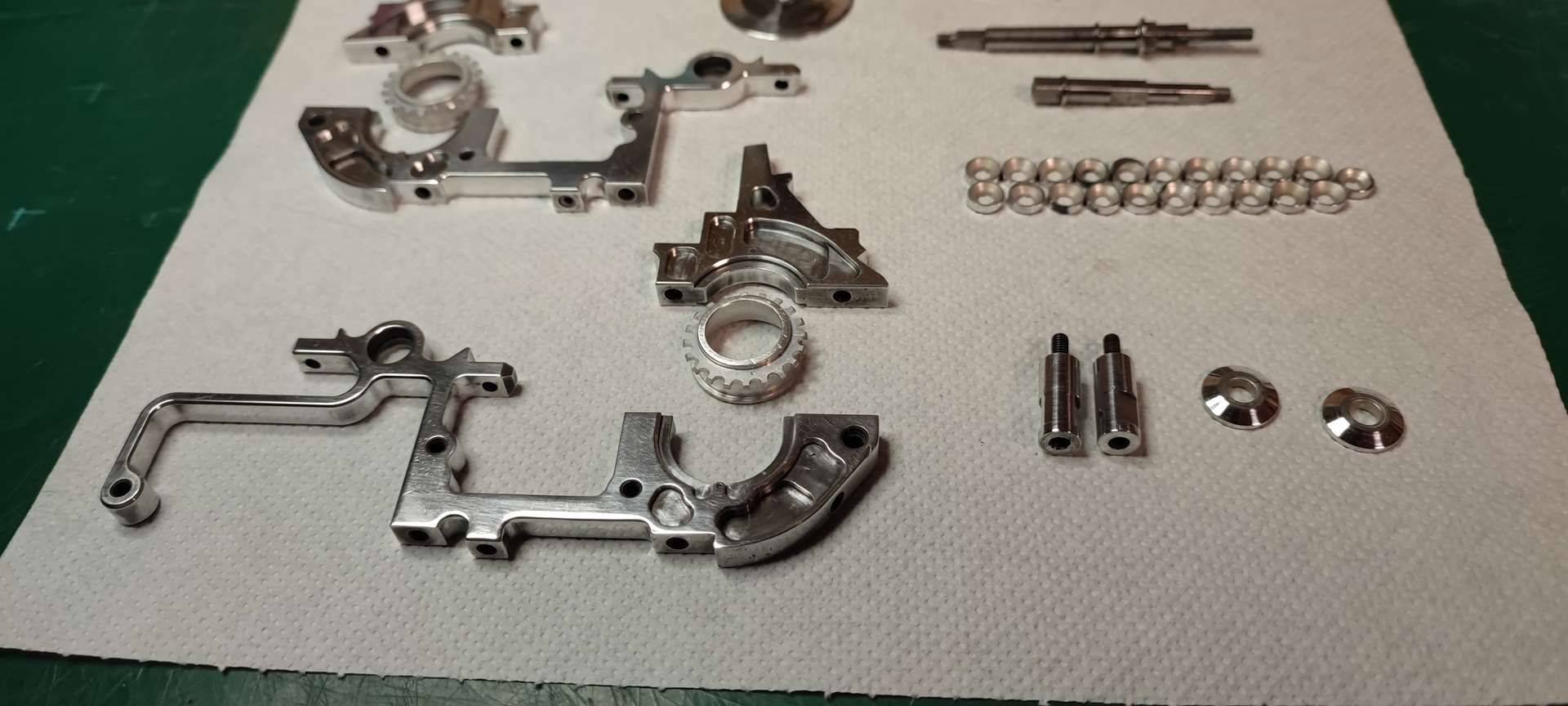

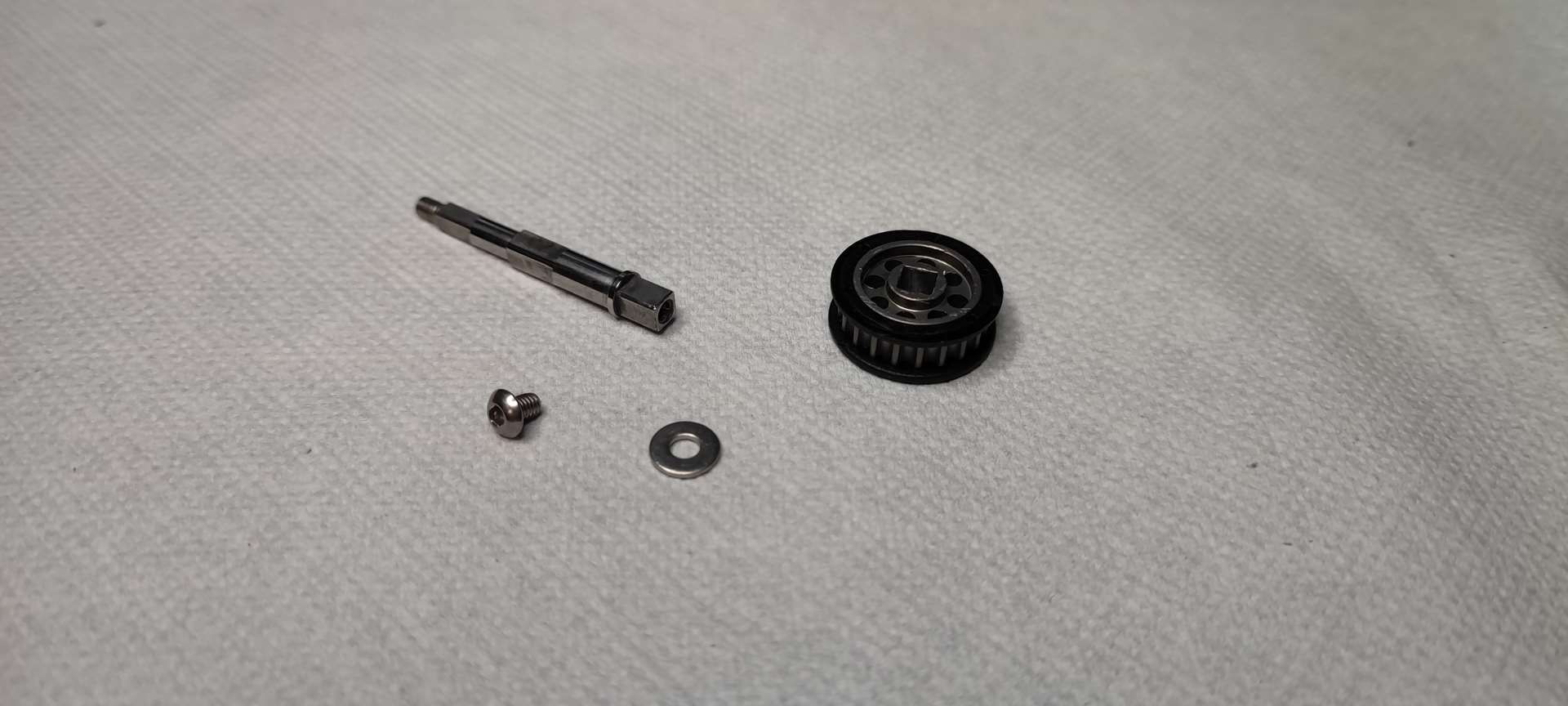

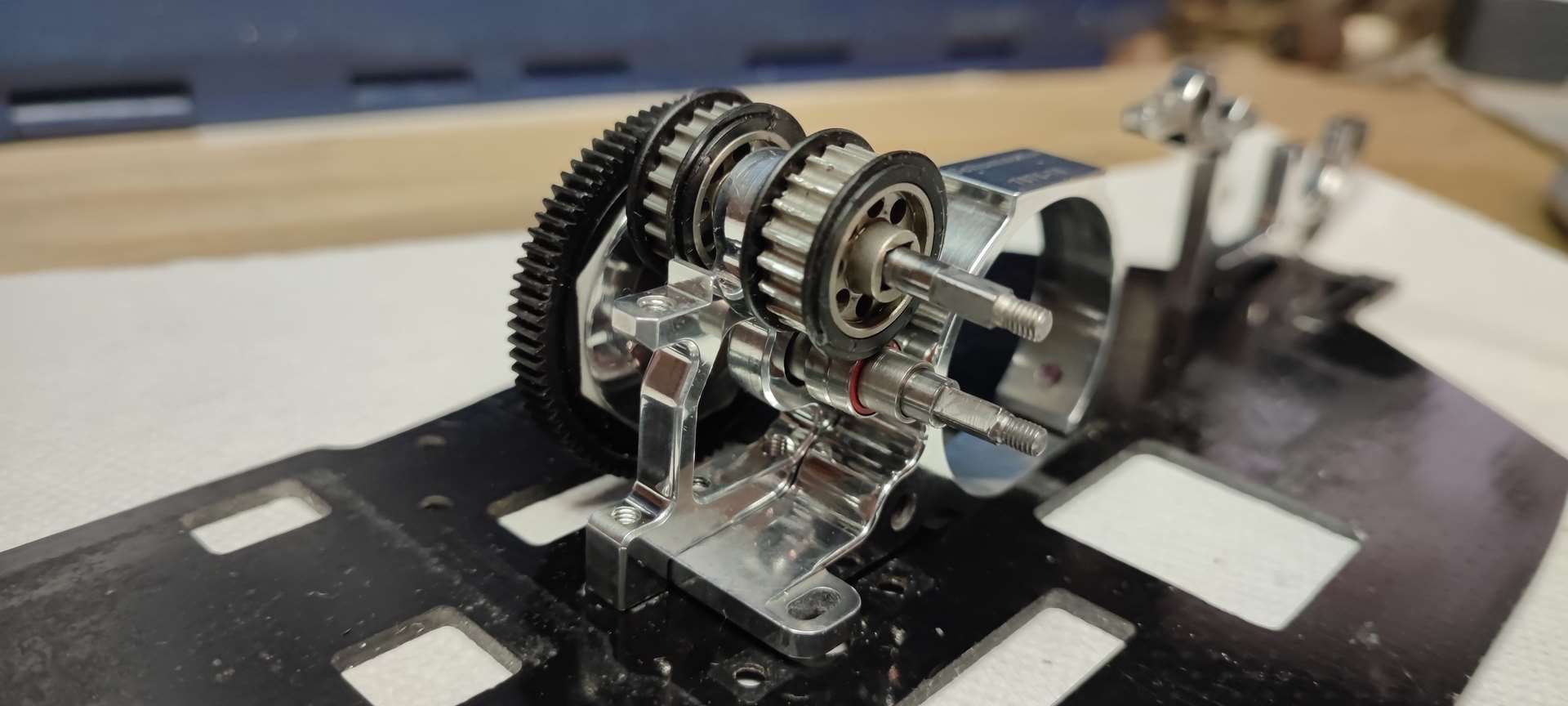

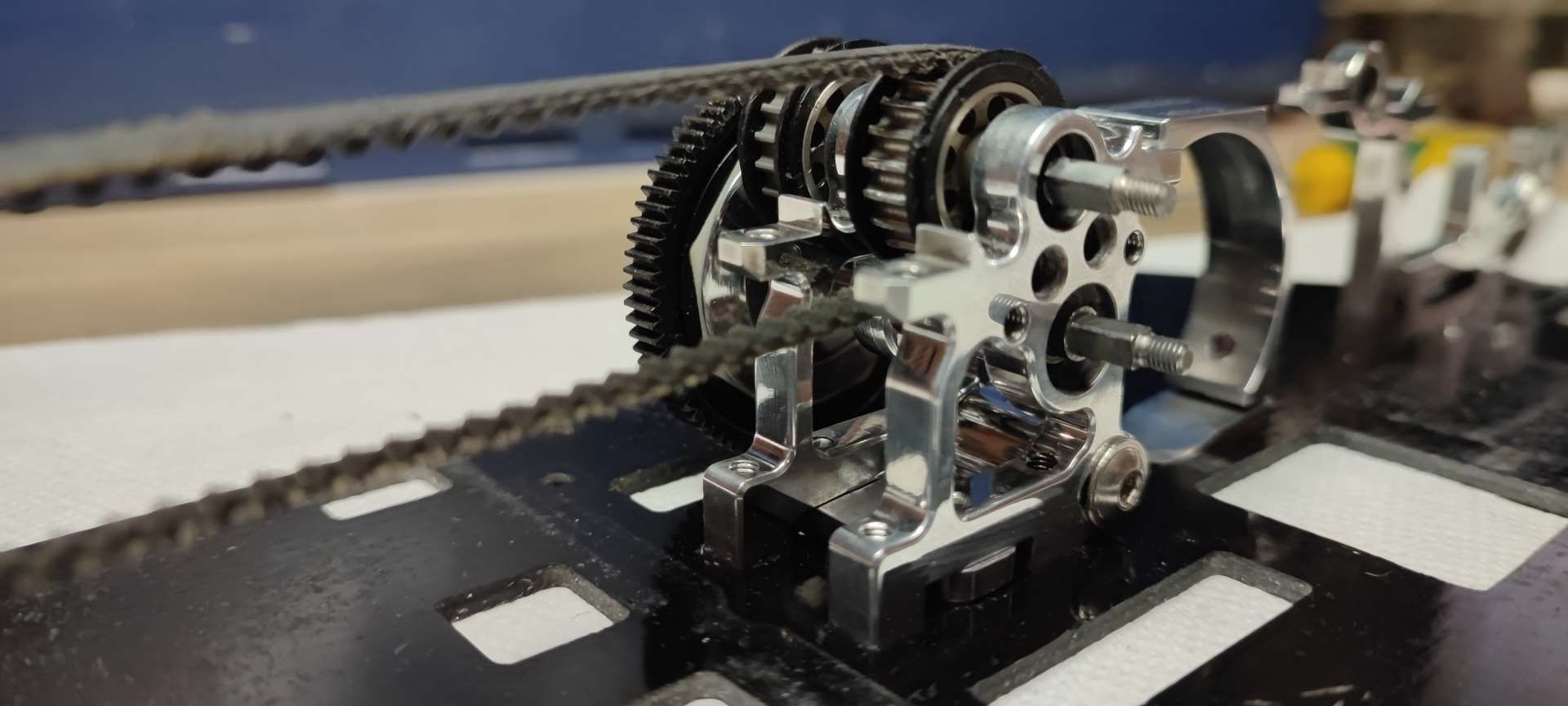

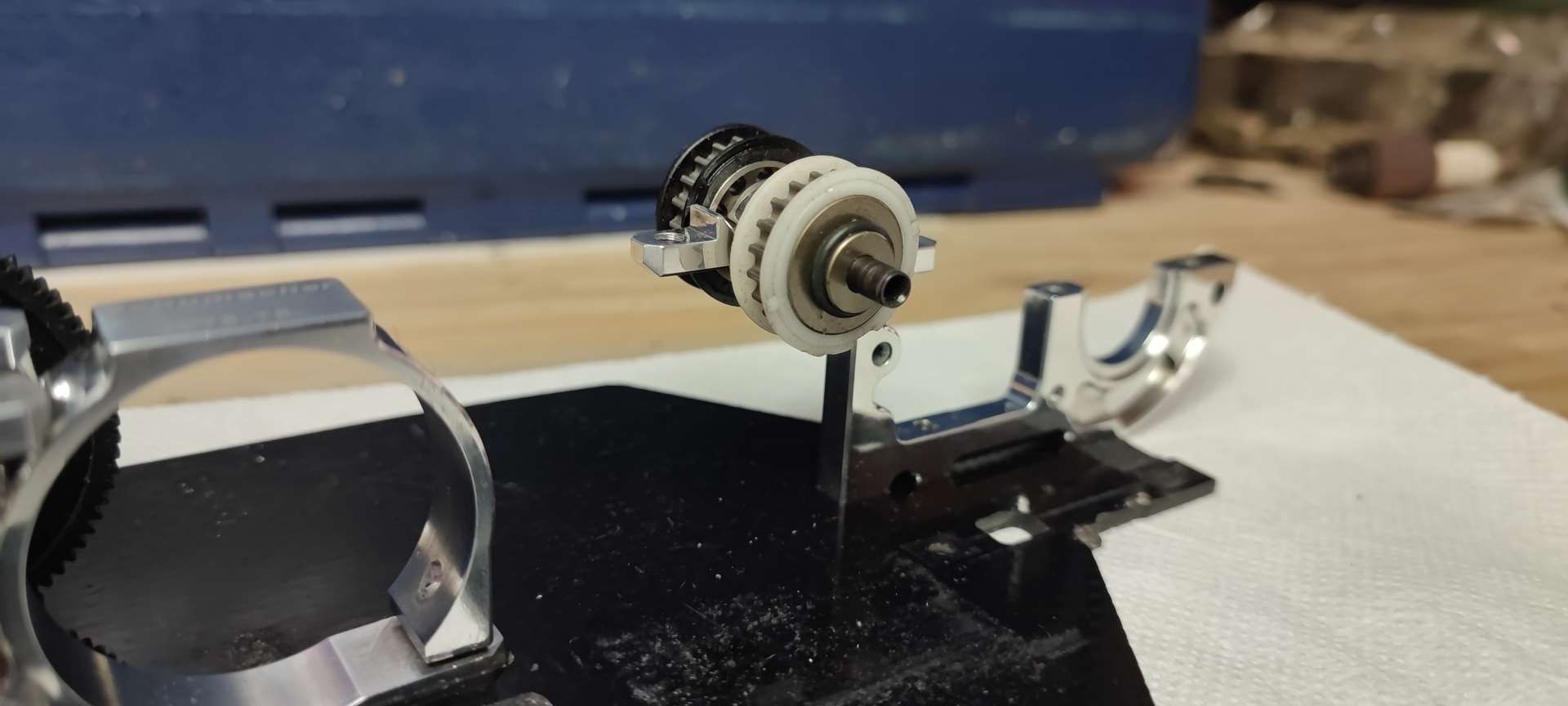

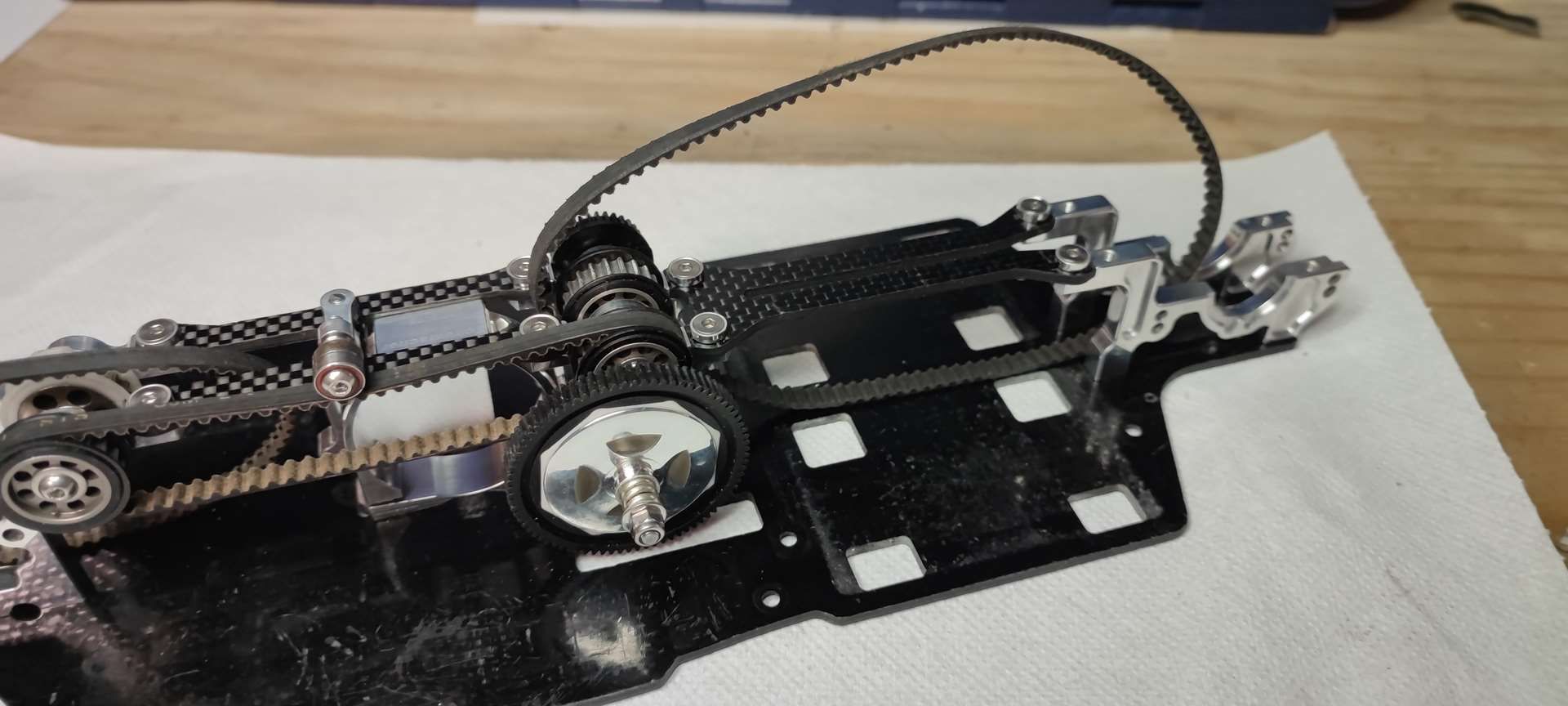

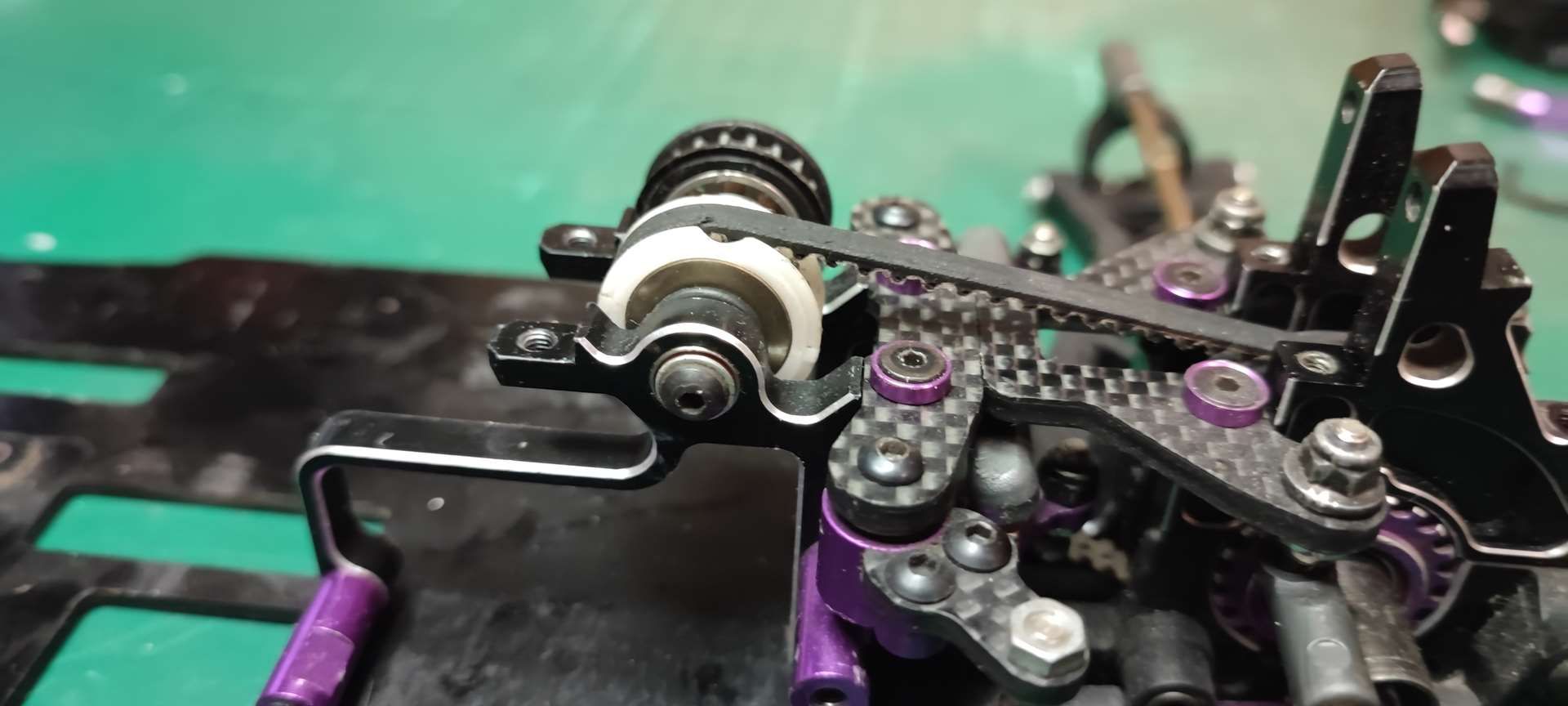

Broken front belt pulley:

File stroke to try to unscrew with a flat screwdriver:

It came, but the other 3 are blocked too, the solution 10 minutes on the wood stove and thermal shock in the freezer... and it comes, phew!!!

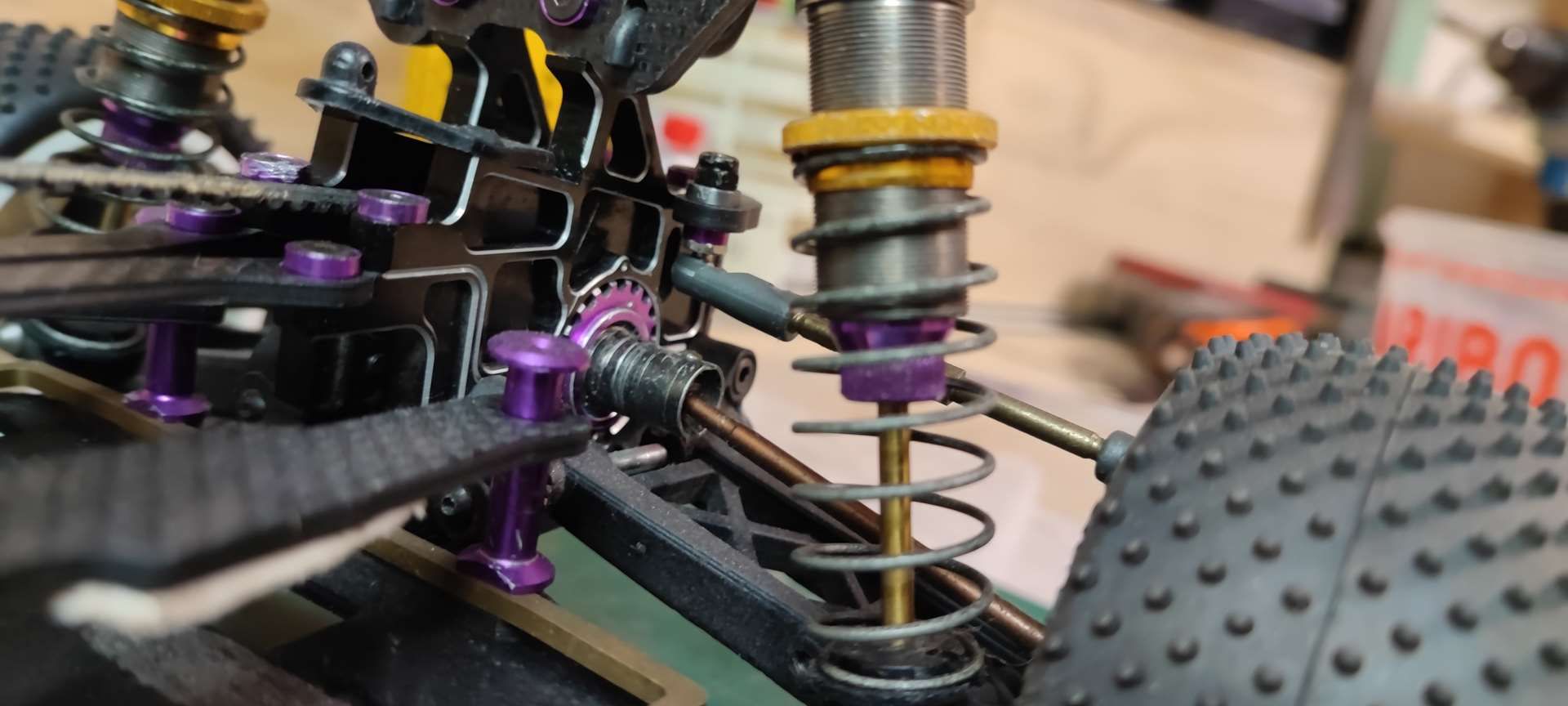

During the dismantling of the fixings of rear triangles, the screws are twisted... he really picked up this poor chassis...

Easy solution when you don't have the right wedges... done with those that milk

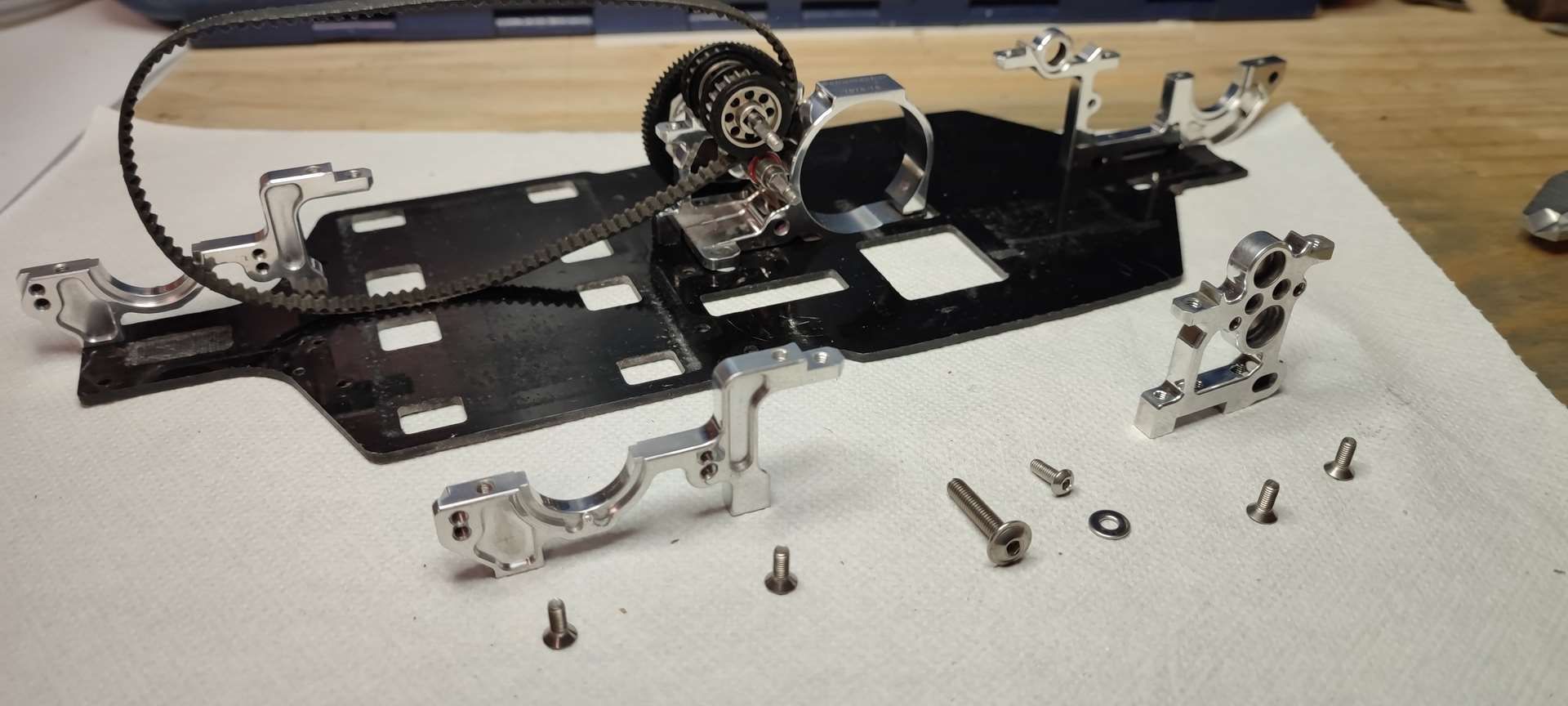

In short, the list of things to do will be long and it will cost me an arm:

- untwist the front bulks

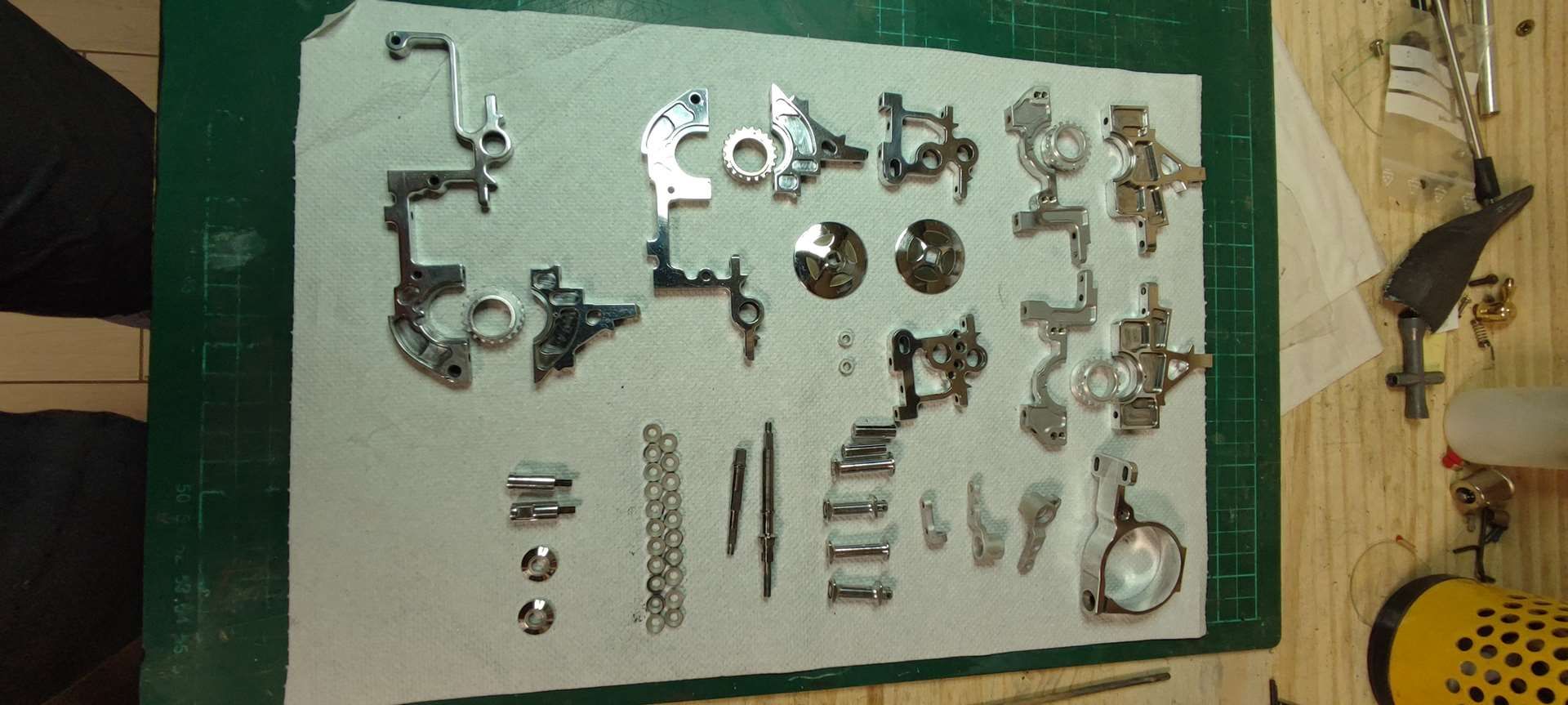

- deanodize all the aluminum parts

- sand and remove as many marked or damaged aluminum parts as possible

- a new frame

- all carbon parts to be changed

- diff flanges

- driving pins for the rims (half was simple piano wire)

- new belts

- new arms

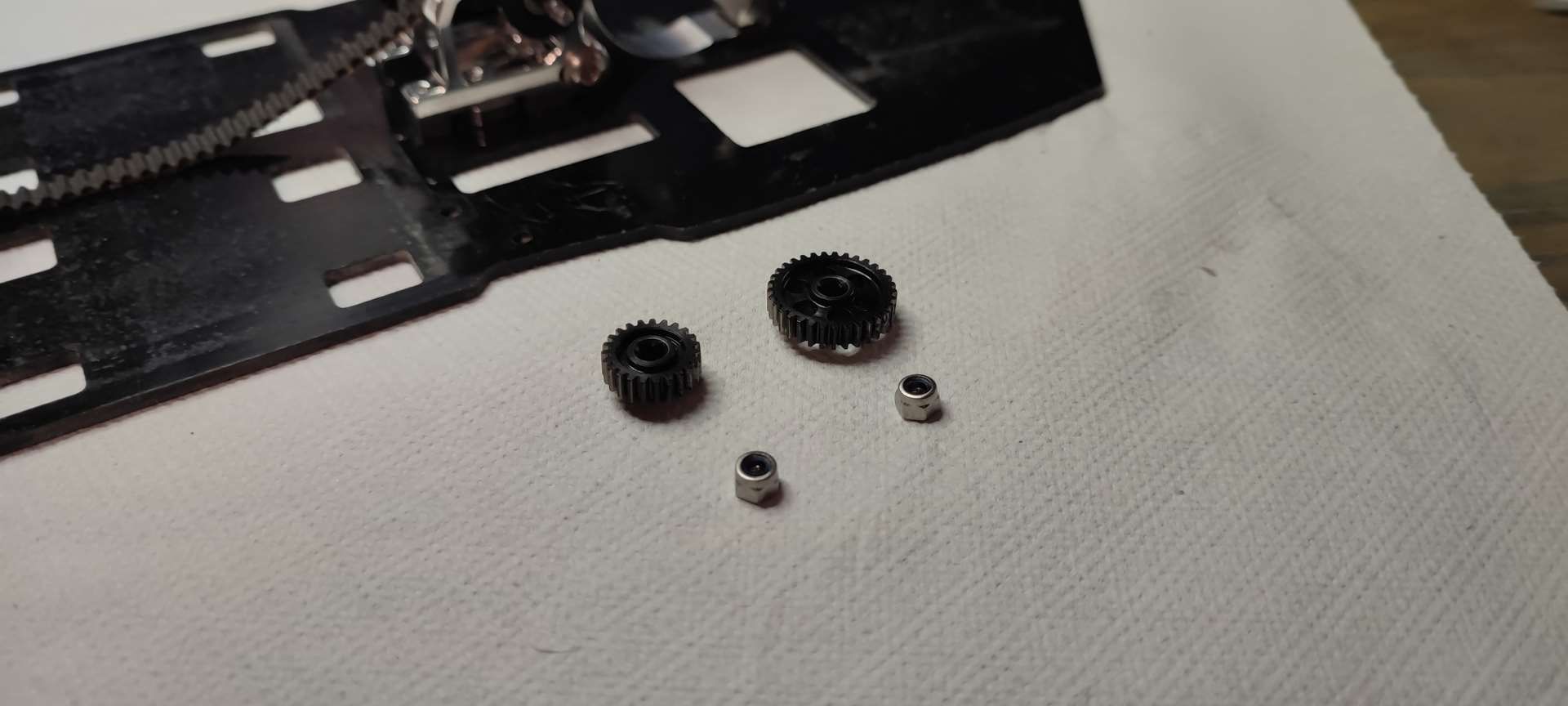

- new diff crowns

- new belt pulleys

- new diff balls

The "luck" is that the rims and tires are new and that there is a blank body...

To be continued...

Jerome