Page 5 of 24

Re: Discussion about possible aluminum transmission and part

Posted: Fri Apr 29, 2011 2:07 pm

by SnoopMaxx

Re: Discussion about possible aluminum transmission and part

Posted: Fri Apr 29, 2011 2:53 pm

by 300D50

That is awesome, thanks a million!

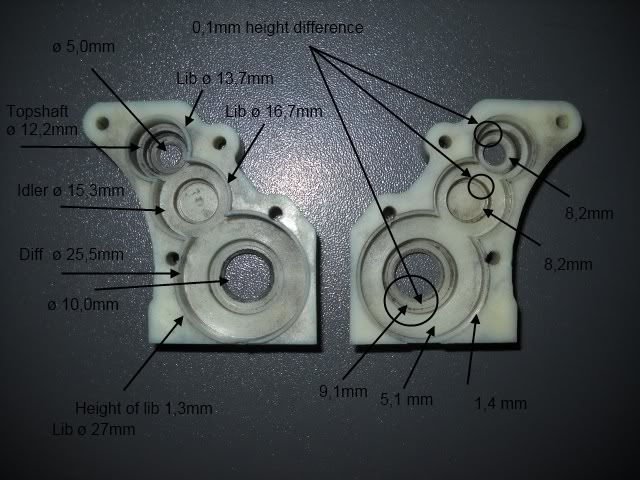

Now I know the stock needs to be at least 1/2x2x4 for the set. Now to rough-model this puppy up!

Is it ok if I use two or three 1/8" dowel pins instead of a raised lip for locating the trans halves?

Re: Discussion about possible aluminum transmission and part

Posted: Fri Apr 29, 2011 2:59 pm

by kaiser

PBR Allstar wrote:if he ends up doing a run of any of these parts do you think doing some in delrin would be a possibility? I really don't want either in aluminum, but would jump all over some delrin parts, and I'm sure a few others on the borard that are more in the racing spectrum would be into them as well.

i'd be all over that. delrin > alloy

Re: Discussion about possible aluminum transmission and part

Posted: Fri Apr 29, 2011 3:06 pm

by SnoopMaxx

300D50 wrote:That is awesome, thanks a million!

Now I know the stock needs to be at least 1/2x2x4 for the set. Now to rough-model this puppy up!

Is it ok if I use two or three 1/8" dowel pins instead of a raised lip for locating the trans halves?

Are you using Nylon 6-6 or Delrin ?

What grade of alloy will you be using ?

I use mostly 6082 T6 when turning parts on my lathe

Morten

Re: Discussion about possible aluminum transmission and part

Posted: Fri Apr 29, 2011 3:34 pm

by 300D50

For this, likely Delrin/Delrin AF on the plastic/composite ones, and 6061-T6 for the aluminum ones.

If made with Delrin AF(Teflon impregnated), the bearings could possibly be eliminated from the trans for race applications. Don't hold me to that though, since I likely am overlooking something... EDIT: like the fact that the AF is 6 times the price of the regular Delrin... so scratch that i guess.

Never worked with 6082, but it seems it has a higher tensile strength. Any reason to use it over 6061 besides the added safety margin?

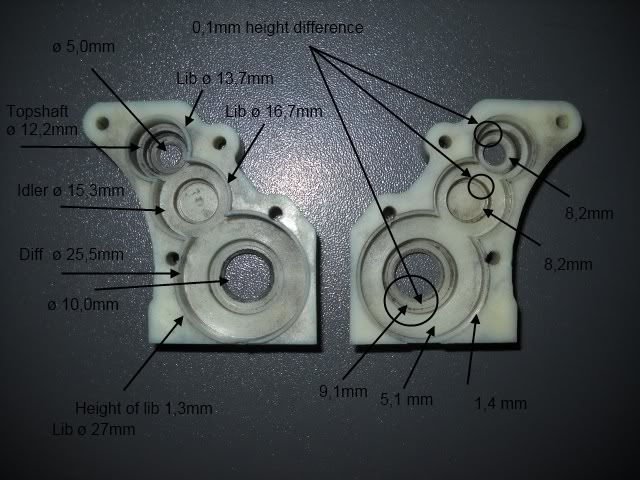

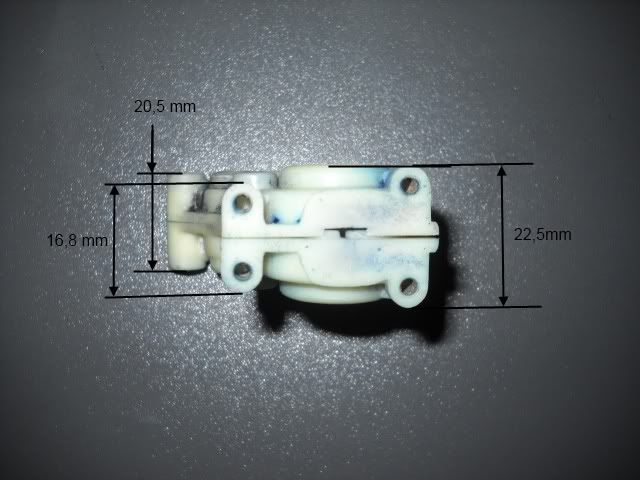

Think you can get a rough depth figure for the bearing bores from the part face? Sorry to keep pestering, I tend to soak up knowledge like a sponge... problem is wringing it out of the grey matter when needed!

Re: Discussion about possible aluminum transmission and part

Posted: Fri Apr 29, 2011 4:18 pm

by SnoopMaxx

I use it as a center in a steel gear

and the 6082 has a better surface finish when milling and turning

as well as being stronger

Right ... Bore depth, inner diameter and outer diameter

Morten

Re: Discussion about possible aluminum transmission and part

Posted: Fri Apr 29, 2011 4:46 pm

by 300D50

Thanks Morten!

Do you use HSS or carbide tooling when you turn aluminum? I find the carbide makes all the difference in surface finish, but it's $$$ up front...

Did you make the gear as well?

Are the forces at work in these gearboxes extreme enough a 6061 center would show more wear? I'm new to this, so I honestly don't know.

Looks like nothing is too small for me to easily machine, stock is reasonable, and this shouldn't take too long to punch out.

Re: Discussion about possible aluminum transmission and part

Posted: Fri Apr 29, 2011 5:18 pm

by SnoopMaxx

Both ...

I buy the gears precut and turn the inside dia. and center on a manual lathe,

Well the standard gears in that gearbox is moulded plastic

There's an upgrade alloy gear set but with a top speed of around 35-40mph they last 5min

The ones I made for Jonny has lasted for over 2½ years with no visible wear

and He use a 5700kv motor on 3s 11.1v LiPo

These trucks normally drive on 7.4v and has a top speed of around 15mph

Just have a look at this video

http://www.youtube.com/user/xjonny26#p/u/5/9Y0i59E66BE

If the prize is right I would consider buying a gearbox, bulkhead and rear mount

Morten

Re: Discussion about possible aluminum transmission and part

Posted: Fri Apr 29, 2011 5:55 pm

by 300D50

That vid is awesome! I have an ear to ear grin on my face right now!

Ah, so you bore the center out to fit, that makes a lot more sense than making the entire gear.

Plastic gears have always made me cringe...

Re: Discussion about possible aluminum transmission and part

Posted: Fri Apr 29, 2011 6:06 pm

by SnoopMaxx

300D50 wrote:That vid is awesome! I have an ear to ear grin on my face right now!

Indeed

Indeed

Ah, so you bore the center out to fit, that makes a lot more sense than making the entire gear.

Yeah it does

Plastic gears have always made me cringe...

ME TOO

If you need any more measurements, just let me know

Morten

Re: Discussion about possible aluminum transmission and part

Posted: Fri Apr 29, 2011 6:28 pm

by 300D50

That should be enough till I get the stuff from Johnboy and can throw it on the CMM.

This weekend just had something come up, so looks like it's 3 weeks out for that.

Re: Discussion about possible aluminum transmission and part

Posted: Fri Apr 29, 2011 11:28 pm

by wyldbill

why dont you see if you can get a hold of the aluminum case that askbob bought from pbr and compare the stock nylon to the aluminum and see which one would be easier to machine.

Re: Discussion about possible aluminum transmission and part

Posted: Sat Apr 30, 2011 6:07 am

by 300D50

I'd rather just reverse engineer the plastic one. Takes the same amount of time either way.

That, and I'd feel a bit shady copying an individuals design vs a corporation/companies. Ethics are funky like that I guess.

Re: Discussion about possible aluminum transmission and part

Posted: Sat Apr 30, 2011 10:03 am

by flipwils11

This is really moving fast, impressive. If the aluminum one is available in time I will have to put it on my next build and get it anodized a cool color.

Re: Discussion about possible aluminum transmission and part

Posted: Mon May 02, 2011 10:57 am

by 300D50

Ok, I'll bite the bullet.

Anyone have an issue with $50 for a case?

Indeed