Page 4 of 5

Re: '91 WC Stealth vs B4

Posted: Thu Jul 24, 2014 5:16 pm

by edwin pibal

ill buy one regardless

Re: '91 WC Stealth vs B4

Posted: Wed Jul 30, 2014 11:27 am

by jbmeyer13

The hope is that we can 3D print the suspension components and CNC the chassis and shock towers. Ultimately we (or anyone else) would need to provide the remaining parts; tranny, battery cup, rear bulkhead (and CF brace), wheels, bearings, motor mount and all hardware. The rear bulkhead needs to be cut with a dremel to accommodate the rear suspension components.

After spending a lot of time analyzing the front end it appears the kick up is just 20 degrees rather than the 25 or 30 typically found on 2WD buggies. To accommodate this may require a CF layup mold to be fabricated.

Re: '91 WC Stealth vs B4

Posted: Wed Jul 30, 2014 11:39 am

by jbmeyer13

One necessary but seemingly difficult item to find is the chassis standoff posts. I checked McMAster-Carr but they don't seem to have the tapered version we need. If anyone has an idea where to find this please advise.

Re: '91 WC Stealth vs B4

Posted: Wed Jul 30, 2014 12:30 pm

by fredswain

I'm not concerned with 100% accuracy here. As long as they are the proper length I'd let the exact shape slide.

Re: '91 WC Stealth vs B4

Posted: Wed Jul 30, 2014 12:56 pm

by jwscab

those profiled standoffs are something easily made in a lathe from regular round rod. I can't recall the dimension of a composite craft worlds buggy standoff, but I suspect it's not a 'standard' length so they would have to be custom trimmed anyway.

if you guys get to the point where the standoffs are necessary, I can help make some.

Re: '91 WC Stealth vs B4

Posted: Wed Jul 30, 2014 1:53 pm

by jbmeyer13

jwscab wrote:those profiled standoffs are something easily made in a lathe from regular round rod. I can't recall the dimension of a composite craft worlds buggy standoff, but I suspect it's not a 'standard' length so they would have to be custom trimmed anyway.

if you guys get to the point where the standoffs are necessary, I can help make some.

I'm pretty sure they are 1" in length. I found these made by Lunsford in 1", 1.25" and 1.5" lengths. However, if you can machine some that's even better

Re: '91 WC Stealth vs B4

Posted: Wed Jul 30, 2014 4:50 pm

by fredswain

Since the top deck sits directly on top of the battery box (what's left of it) on the rear bulkhead, figuring out the height should be easy.

Re: '91 WC Stealth vs B4

Posted: Thu Aug 28, 2014 10:23 am

by fredswain

Here's a quick but crappy screenshot of the Stealth car top deck model.

Re: '91 WC Stealth vs B4

Posted: Thu Aug 28, 2014 1:35 pm

by jbmeyer13

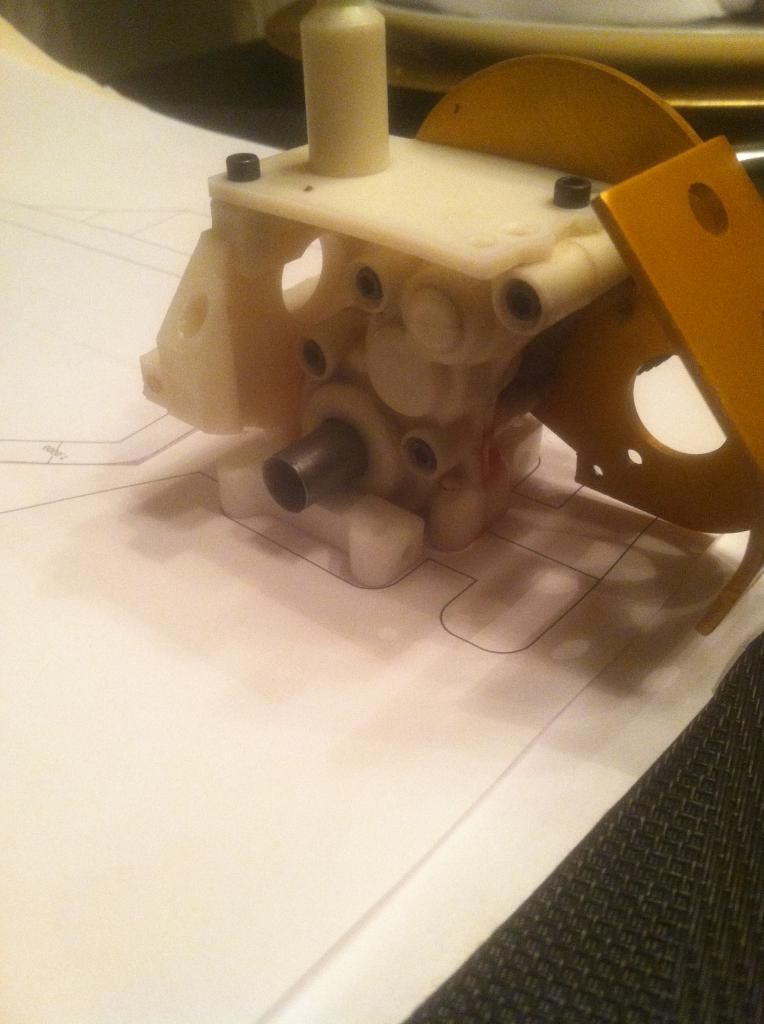

Main Chassis in progress..

Re: '91 WC Stealth vs B4

Posted: Thu Aug 28, 2014 6:37 pm

by jbmeyer13

I have my CAD file of the main chassis 99% done; just some final tweaks and it will be ready to go (hopefully tomorrow). Then on to creating a mold for the chassis

Re: '91 WC Stealth vs B4

Posted: Tue Sep 02, 2014 6:07 pm

by jbmeyer13

Main Chassis CAD finished

Re: '91 WC Stealth vs B4

Posted: Tue Sep 02, 2014 10:18 pm

by edwin pibal

wow dude!

I feel like I need to be chucking money at you now to make I get one !!

ed

Re: '91 WC Stealth vs B4

Posted: Thu Sep 18, 2014 4:33 pm

by jbmeyer13

Just finished custom machined standoffs for top deck

NIK91 front bulkhead bottom width and rear mounting blocks are exact match to our calculated measurements so they line up perfectly over the mock up.

Re: '91 WC Stealth vs B4

Posted: Thu Sep 18, 2014 5:38 pm

by littleVETTE

great stuff justin.

are you guys still going through with your version of the 1991 stealth?

Re: '91 WC Stealth vs B4

Posted: Thu Sep 18, 2014 6:57 pm

by jbmeyer13

littleVETTE wrote:great stuff justin.

are you guys still going through with your version of the 1991 stealth?

Definitely moving forward with having a chassis cut. The NIX components are first rate and thus far tie out to the dimensions we have so it doesn't appear to be any reason to replicate those pieces. The sole exception may be the front bulkhead depending on how things play out. The main reason to move forward with the chassis is that there are some subtle differences cosmetically and also because I want to have control over the thickness and type of CF used. If it turns out that the kick up ends up being 20 degrees then we'll have a mold created to ensure optimal accuracy.