Page 3 of 7

Re: Yet another Customised Optima Mid Custom Special

Posted: Wed Mar 19, 2014 4:34 am

by alcyon

HKS_TRD wrote:Yeah I want atleast one. That's better than the vintage ones I have as its a direct copy of the original unlike the ones I have. I will be getting it anodised gold and putting it on the Turbo Mid SE-X. If the 21st Century Mid wasn't done I'd put it on that. I wonder if a Lazer bulkhead and upper deck could be made to fit a mid. Do you think it would be possible to have the A&L motor plate copied?

I have an A&L Optima Mid motor plate and a red GPM Lazer ZX motor plate. I could ask my machinist if he could make it, but again, how many people actually want them ?

Re: Yet another Customised Optima Mid Custom Special

Posted: Wed Mar 19, 2014 4:39 am

by HKS_TRD

You make a good point, I guess the level of interest would be equivalent to that for the CNC layshaft.

Are you considering doing gearbox cases, or the front one in particular?

We must continue the quest for the ultimate Optima Mid, even though there is barely any mid DNA left in our creations

Re: Yet another Customised Optima Mid Custom Special

Posted: Wed Mar 19, 2014 4:43 am

by alcyon

HKS_TRD wrote:You make a good point, I guess the level of interest would be equivalent to that for the CNC layshaft.

Are you considering doing gearbox cases, or the front one in particular?

We must continue the quest for the ultimate Optima Mid, even though there is barely any mid DNA left in our creations

Yes I did consider making the gearboxes, but the cost is very high. I am more interested in the fronts though. Because I see supply is very limited for original OT-84s. I was lucky and managed to score a NIP OT-84 for U$30 a month back. If I were to make them, my selling cost would be U$30 for the fronts only. Its that expensive because I cannot mold these parts but machine them.

Re: Yet another Customised Optima Mid Custom Special

Posted: Wed Mar 19, 2014 4:46 am

by HKS_TRD

Would that be nylon or alloy?

I would buy a couple at that price.

Have you looked into a design similar to what oosh did for the lazer i.e. carbon sides and alloy cantre piece?

Re: Yet another Customised Optima Mid Custom Special

Posted: Wed Mar 19, 2014 4:48 am

by alcyon

HKS_TRD wrote:Would that be nylon or alloy?

I would buy a couple at that price.

Have you looked into a design similar to what oosh did for the lazer i.e. carbon sides and alloy cantre piece?

that would in complete hard blue, white or black nylon. I imagine it would be more expensive if alloy. But alloy isn't a bad idea if you want a bulletproof car. The front threads do strip if you disassemble the car too many times.

Re: Yet another Customised Optima Mid Custom Special

Posted: Wed Mar 19, 2014 4:57 am

by HKS_TRD

I'm rather interested in either blue nylon or the alloy.

Maybe its worth looking into making the pivot block a separate piece and maybe having the gearbox divided in a front and rear half like a Lazer. That and carbon side plates would make it much stronger

I notice your bulkhead has the extra hole to allow one to use the custom motor brace I had made, I had to drill and tap the extra hole on mine

Re: Yet another Customised Optima Mid Custom Special

Posted: Wed Mar 19, 2014 8:38 pm

by alcyon

HKS_TRD wrote:I'm rather interested in either blue nylon or the alloy.

Maybe its worth looking into making the pivot block a separate piece and maybe having the gearbox divided in a front and rear half like a Lazer. That and carbon side plates would make it much stronger

I notice your bulkhead has the extra hole to allow one to use the custom motor brace I had made, I had to drill and tap the extra hole on mine

Yes that extra hole is a good idea actually. Having 2 screws to hold that part is better than one. BTW why hasn't fibrelyte added that custom brace you designed to their site? Could you ask them to add it ? Cant speak for others but I would be very interested in the ZXR MK2 type brace like the one you made for the Mid.

Re: Yet another Customised Optima Mid Custom Special

Posted: Wed Mar 19, 2014 8:44 pm

by HKS_TRD

Fibrelyte have other updating they also need to make to the Kyosho section of their site (the lazer pages are all a bit jumbled and not all labelled correcty), but if you email them they should be able to make you one, though I have not heard back from them about my tub and other custom parts for a while

I am considering making another alteration to the design of that part, to remove the two holes on the rear section and make the shape more like that of the Lazer motor brace, just to make it a little more custom, the one I have may go on the SE or I may sell it

Re: Yet another Customised Optima Mid Custom Special

Posted: Sun Mar 23, 2014 1:16 am

by alcyon

Tested the car today . The durangos (dingos) were there. At first the mid handled great. It took the rough stuff well but then handling started to deteriorate .It was like it wasn't tracking straight very well, I had to make major corrections while the car is supposed to be going straight, then it also over steered on power out of the corners. It wasnt as easy to drive as last week. There was no more belt skip.i surmised my front ball diff may be not tight enough so i tightened it and try again. Still it wasnt really good. The dingos were running circles around me. However even in this condition the mid jumped better than them. My mid consistently cleared the huge jump while the dingos didnt dare to. They landed before the 2nd peak. I pulled my car off and found the probllem. The rear ball diff wasnt working anymore. The grease on the balls are gone, so they are dry now, causing the diff to be notchy. As of now i am preparing my geardiffs. The rear wil be filled with 300000 oil half filled and the front with putty. Next week..revenge of the optima mid !!!! I hope i can finally show the modern shaft cars a thing or two..And hopefully the bevel gears wont separate like it did BITD.

Re: Yet another Customised Optima Mid Custom Special

Posted: Sun Mar 23, 2014 8:50 pm

by Seabass

Why not just rebuild the ball diffs? gear diffs can be tricky to get right with all the different oils out there. You may add oil to diff and find out that it doesn't meet your needs giving you two options, drive it like it is or tear it down and try a different oil.

Rebuild your ball diff and be done. Do regular maintenance and you won't have this problem again.

Re: Yet another Customised Optima Mid Custom Special

Posted: Sun Mar 23, 2014 9:33 pm

by Coelacanth

I've heard it was the other way 'round...the Optima gear diffs were so good, they were practically maintenance-free, requiring no adjustments once you packed them with the right grease. It was the ball diffs that were far more finicky, at least for the average racer who didn't want to tinker with the gearbox every weekend.

Re: Yet another Customised Optima Mid Custom Special

Posted: Mon Mar 24, 2014 12:45 am

by alcyon

Seabass wrote:Why not just rebuild the ball diffs? gear diffs can be tricky to get right with all the different oils out there. You may add oil to diff and find out that it doesn't meet your needs giving you two options, drive it like it is or tear it down and try a different oil.

Rebuild your ball diff and be done. Do regular maintenance and you won't have this problem again.

The ball diffs require too much maintenance. I estimate with greasing it can only run 10 packs without the lube drying off. I really am trying to avoid dissasembling the gearboxes and resealing belt covers. Its too much work on the optima mid. Also wears off the threads on the gearboxes. With the geardiffs with modern hard silicone oil and filled only half should ensure a rear diff that does not leak and wont unload. For the front diff i will use putty to give the car stability and reduce some steering. I just hope the bevel wont seperate from the shaft as it has happened to me before. But back then i was running gear diffs without any oils. Cant spend too much time on rc cars. Gotta spend time with my kids who are growing up. The lazer is a lot easier to maintain at least where diff maintenance is concerned.

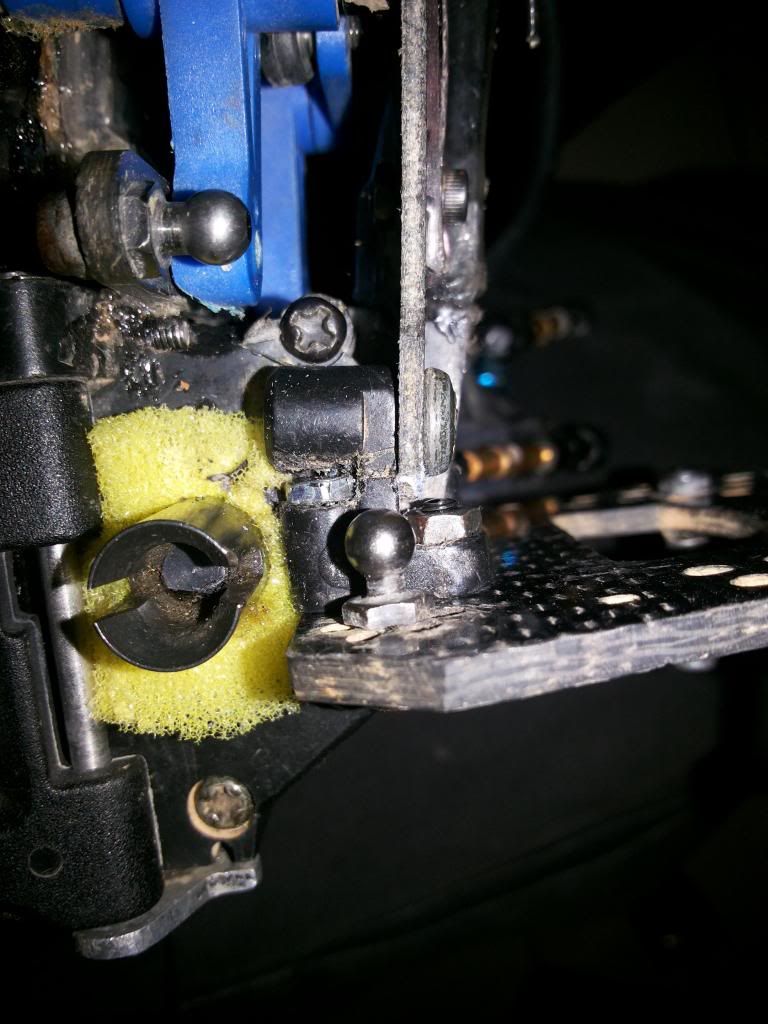

one thing I noticed though is the geardiffs has a tendency to float inside the garbox because the 8x14 bearing has too much sidewards gap. luckily these days finding the right shims are easy. I tried shimming my rear gear diff last night and now it has zero play, yet the drive line is smooth. I will be adding some punched sponge protection on the diff outdrives near those bearings for extra protection. I found a little sand in my gearbox, I think it could be because the rear wing stay sheared off from the gearbox.

Re: Yet another Customised Optima Mid Custom Special

Posted: Mon Mar 24, 2014 7:21 am

by adam lancia

You can just use the Optima Mid gear and belt pulley with the Lazer diff parts... I think anyways...

Re: Yet another Customised Optima Mid Custom Special

Posted: Mon Mar 24, 2014 8:15 pm

by alcyon

adam lancia wrote:You can just use the Optima Mid gear and belt pulley with the Lazer diff parts... I think anyways...

That wouldn't do any good as the problem is in the design of the optima mid itself. The gearboxes must be taken apart in halves. And then the belt covers need to be re sealed again. Last night I spent 2 hours on my mid and still not ready yet. I found that the rear sprocket was too tight so had to remove a shim. I managed to put the gearboxes together and sealed the lower belt cover completely, and also I sealed the diff bearings by using dishwashing sponge that I cut thinner, then used a 6mm single hole punch to make a hole in the center of the sponge to let the diff outdrive go through. Then a little selleys silicone sealant to stick the sponge to the outdrives. I will post pics tonight of the rebuild process. Tonight my target is to place back all electronics, top deck and seal the upper belt covers. Then will move to suspension and undertray the next day. Phew this is tiring work !

Re: Yet another Customised Optima Mid Custom Special

Posted: Tue Mar 25, 2014 10:13 pm

by alcyon

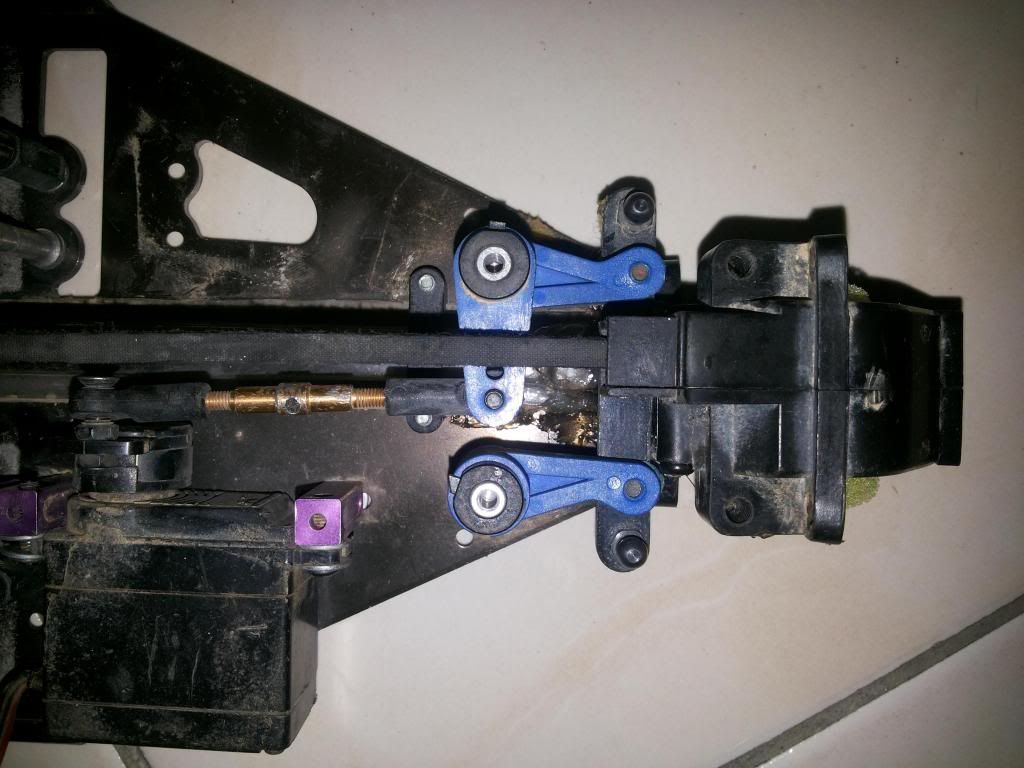

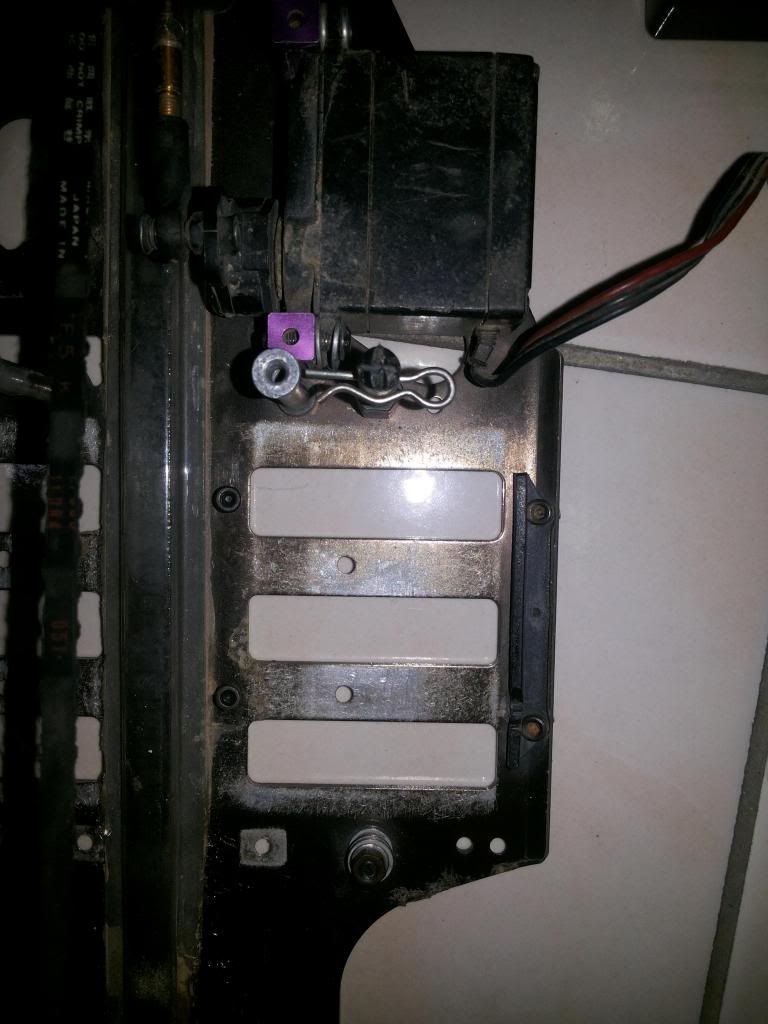

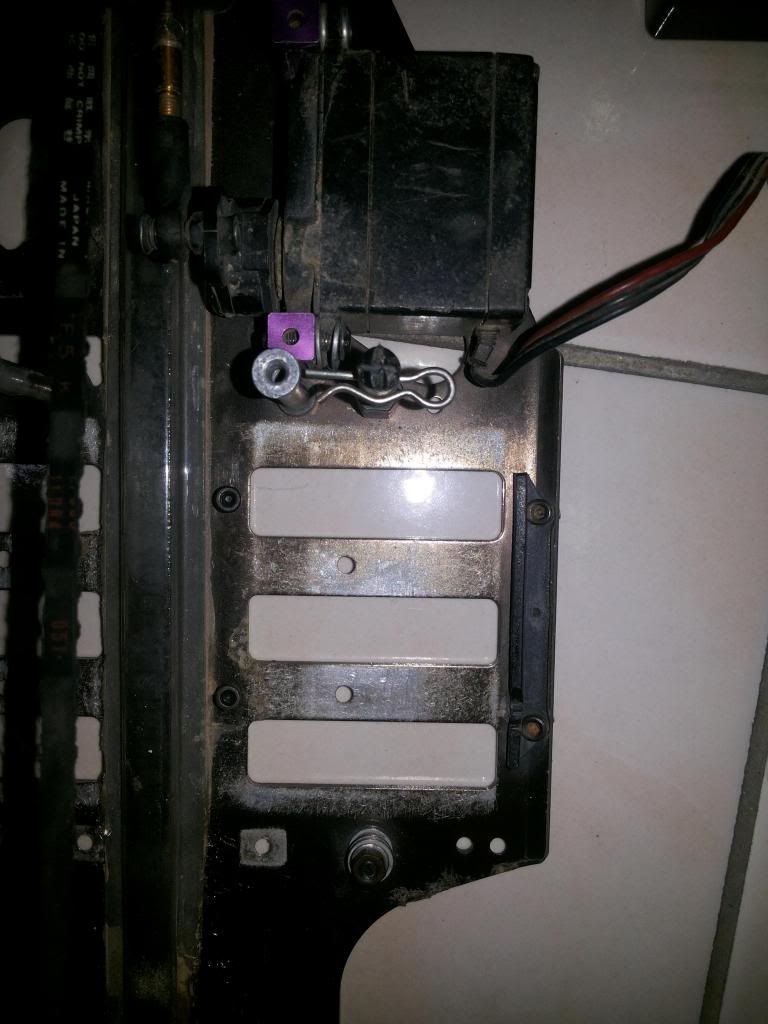

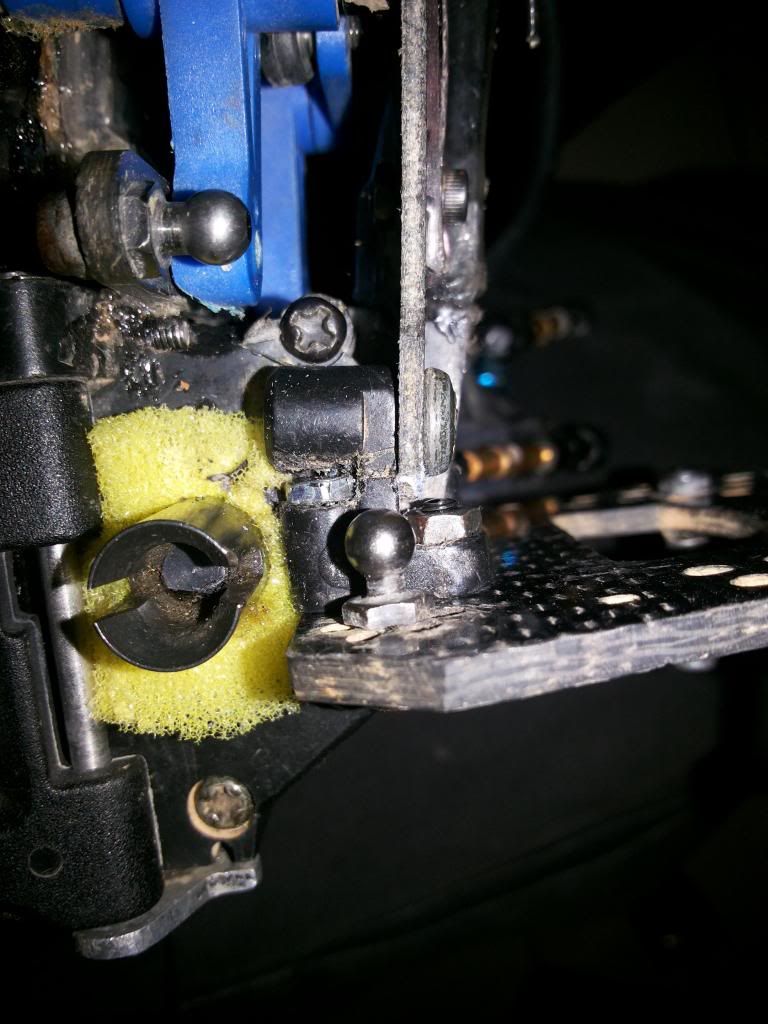

Sealed with sponge, my diff outdrive bearings should be protected.

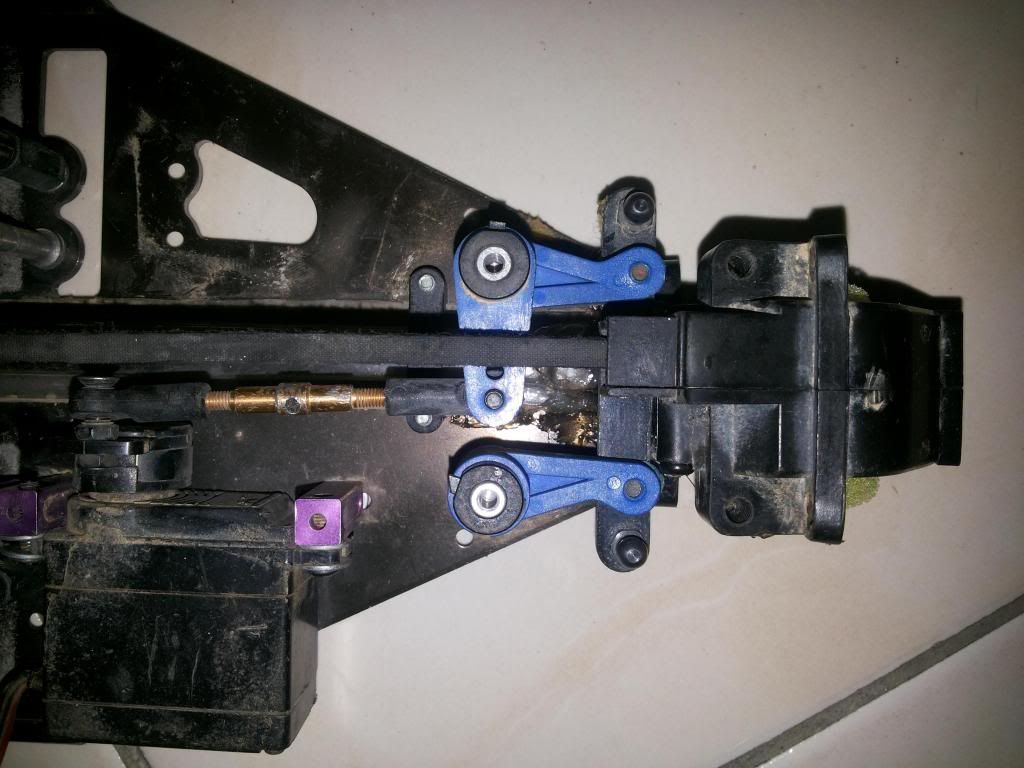

The steering linkage is impossible to adjust with the top deck on, so I do it now.

I decide to add some support for the lipo saddle pack, as you can see the outer part of the chassis already has a stopper, so I drilled two 2mm holes near towards the belt cover and screwed in two M2.5 Cap screws to support the lipo from shifting around.

I also found that of all 4 holes securing the front shock towers are stripped. Since I used a M3 nut to secure the upper screws, the lower ones don't really support the tower. Because of that I found a crack on one of the upper nubs on the gearbox. This means if that breaks, the front tower will only be supported with one screw. I tried slotting a M3 nut into the crevice of the lower holes but its way to tight. I will be getting a M2.5 nut and a M2.5 x 14L screw which should be able to fit in the crevice and offer additional support to the tower, thus preventing my front gearbox from breaking at the upper mounting holes. Newsflash. Just came from the local bolts shop and asked for a thinnest m3 nut. The standard ones were 2.3mm thick. The ones i got were 1.8mm thick, just what i needed. These should slide in the crevice perfectly and have the strength of m3 screws holding the front tower.

While these thin nuts could actually fit in, I had no choice but to use a 3mm drill bit and enlarge a bit the crevice. This is because the shock tower is mounted at about a 5 degree inclination, so I needed to have a little bit of space to make sure the nut is perpendicular to the inclination. It worked like a charm as you can see in the pic above.

The drive line is smooth eventhough I used my most worn out gear sprocket. One thing I aint too happy about is both the gear diffs are not hard enough. Even with the front with putty, it seems to be too soft. However the front is still noticeably harder than the rear so it s best I reserve judgement till I drive it, I don't want to tear down the gearboxes yet again. The car is tracking straight forwards but it has this annoying habit of pulling right when I put it in reverse. I tried adjusting the turnbuckles but to no avail. But tracking straight forwards is more important of course.