Page 10 of 24

Re: Discussion about possible aluminum transmission and part

Posted: Fri Jun 24, 2011 9:14 am

by scr8p

ya, too many dowels. i think the one on the bottom would actually be in the way of the mounting screws anyway. that's how it looks in that pic anyway. it might not be...

the associated trans gears should be run dry. they are self-lubricating. the only kind of grease that should be anywhere inside that trans is on the diff balls. so there shouldn't be anything that could run out. i don't see much chance of dirt getting inside with 2 mating machined surfaces either. but, i guess it could happen.

Re: Discussion about possible aluminum transmission and part

Posted: Fri Jun 24, 2011 9:42 am

by Johnboy72

This thing will be a tank. I appreciate everyone giving walt feedback because without it, walt would truly over engineer and over build it. Lol

Re: Discussion about possible aluminum transmission and part

Posted: Fri Jun 24, 2011 12:04 pm

by SnoopMaxx

Walt

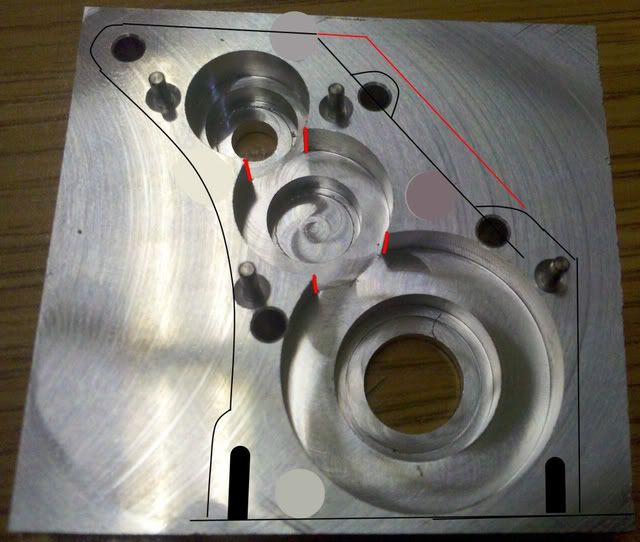

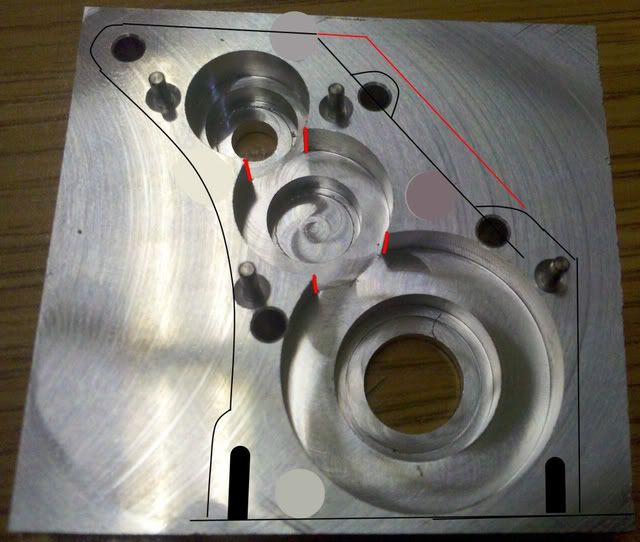

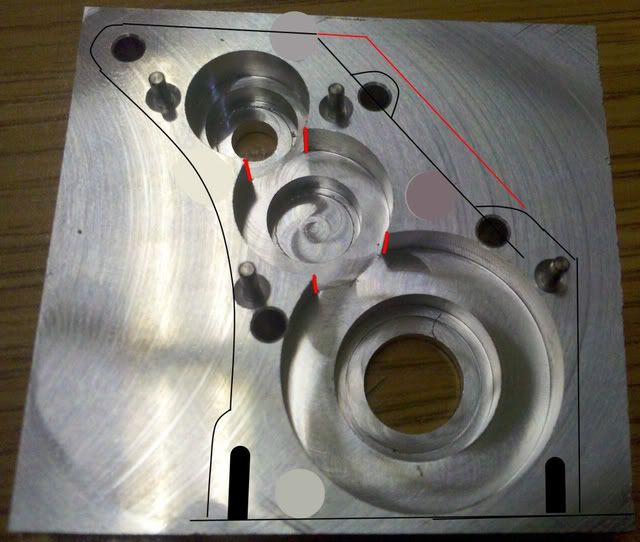

I had a good look at the prototype case

And I think you have too many dowels

Lay the original nylon case half over the alloy, and you'll know what I'm talking about

The thin red is just a suggestion to make it look like the 6 gear case

Will the outside be flush like on the MIP and 6 gear case ?

I trimmed the inside of my case, ca 0.6mm wider and yes it was just to give it a little radius (thick red in your photo)

Morten

Re: Discussion about possible aluminum transmission and part

Posted: Fri Jun 24, 2011 1:18 pm

by wyldbill

i vote for the tube idea that jwscab suggested, just one in each corner hole in stead of all 4. that sounds the easiest just oversise the holes slightly and install some brass tube. i really wish that Birdsboro was still racing on the concrete, i could have oval tested them for you. 1 in the truck and 1 in the edm would have been sweet.

Re: Discussion about possible aluminum transmission and part

Posted: Fri Jun 24, 2011 3:29 pm

by SnoopMaxx

Not a good idea Wyldbill

Look at the photos, 2 of the holes are too close to the main gear, in order to make that work you will have to relocate the holes and make a new motorplate .... It's only possible on the upper holes

The idea is to make a gear box that works with the standard chassis and motorplate

Morten

Re: Discussion about possible aluminum transmission and part

Posted: Fri Jun 24, 2011 3:49 pm

by 300D50

Thank's for the input everyone.

The hollow dowels would end up being a PITA to source and/or manufacture, I've been there with actual car transmission adapter plates...

I also have about 1000(no joke, the bag is huge) 1/16" diameter 5/16" long dowels, so it isn't a big problem to supply them and a few extras if needed. Price point would be unchanged since i'll never end up using them all to begin with.

The dowels were placed so as to not interfere with the screw holes, I just didn't machine further than was needed to get the geartrain tested.

The reason for so many dowels is a little less obvious.

First of all, I'll be making a few of these out of delrin, and those could use the added rigidity.

Secondly, they are being used to align the parts to a fixture during a second operation, and I'd rather have them super-rigid during that, and even more so with the delrin since it does like to flex a bit.

It's actually cheaper for me to prototype everything in Aluminum due to the price of the delrin and the fact that I can recycle the chips. Who'd think plastic is twice the cost of the same size aluminum stock...

Looks like we're getting a small radius on the edges, and in an odd twist it's cutting down the cycle time by a few seconds!

Re: Discussion about possible aluminum transmission and part

Posted: Fri Jun 24, 2011 4:29 pm

by SnoopMaxx

Two of the dowel will need to go mate, they are at the edge of the case

Any chance you could use the screw holes as fixtures when you mill the outer part ?

Morten

ahh wait you have to countersink the screw holes

Re: Discussion about possible aluminum transmission and part

Posted: Fri Jun 24, 2011 6:08 pm

by Johnboy72

Question...what trans did you use Walt? Is this just an aluminum replacement or is this the 6 gearbox looking transmission using stealth gears inside?

Re: Discussion about possible aluminum transmission and part

Posted: Fri Jun 24, 2011 6:25 pm

by 300D50

Johnboy:

It's the replacement, but the model can easily be tweaked to work with either form factor.

I assume it's just the 3 gears going in a look-alike housing that allows it to bolt right up to existing cars?

Morten:

Which ones would have to go?

Everything is nicely within the envelope of the existing housing as far as my solid models are concerned, I just never milled the outer profile because I don't have the fixture completed. It might look worse than it is due to the angle of the photo and the fact that the dowel holes were spot drilled the same depth as the main screw holes were.

Re: Discussion about possible aluminum transmission and part

Posted: Fri Jun 24, 2011 7:59 pm

by SnoopMaxx

Walt

I removed 4 of the dowels that I think is not needed because the 4 screws also help strengthen the case but if they are inside the case halves ..

It might just be the angle of the photo then,

here's a before and after .... lol

Just do your thing mate

I can't wait to see the outer case milled

Morten

Re: Discussion about possible aluminum transmission and part

Posted: Fri Jun 24, 2011 8:23 pm

by 300D50

The screw holes won't do much to help align the case, since they are over-sized to allow the screw to pass.

The trick that the nylon housings use of under-sizing the holes by a thousandth or so won't work that well in aluminum either.

They do however apply a clamping force to keep the halves together, which is needed.

The angle of the photo is a big factor, as well as that errant spot drill countersinks. They make the dowels look a lot bigger than they are.

Please don't think I'm trying to do the whole "I know more, so it's my way or the highway" ordeal, I'm just trying to explain my reasoning. I tend to make things so that they function well, last, and look good.

I'm also a slight perfectionist who's used to making precision parts, so it tends to carry over a bit...

Re: Discussion about possible aluminum transmission and part

Posted: Fri Jun 24, 2011 8:47 pm

by SnoopMaxx

300D50 wrote:

I'm also a slight perfectionist who's used to making precision parts, so it tends to carry over a bit...

That's just like me

and I know what your talking about, regarding machining procedures

Morten

Re: Discussion about possible aluminum transmission and part

Posted: Mon Jun 27, 2011 2:15 pm

by 300D50

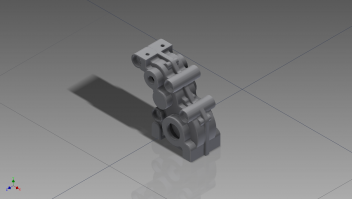

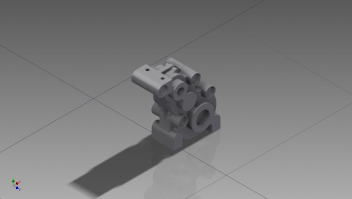

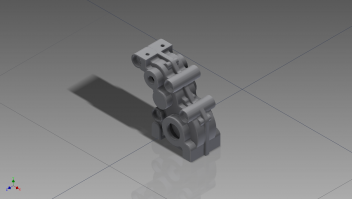

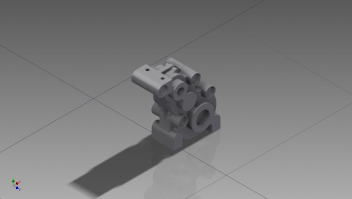

Another day in paradise...

click for larger

Comes in at a little under 17 grams a side, or roughly double the weight of the nylon version.

Re: Discussion about possible aluminum transmission and part

Posted: Mon Jun 27, 2011 3:40 pm

by SnoopMaxx

Oh my

I'm astounded by the detail, no wonder Jonny says you sometimes over engineer parts

When will you have the outer case prototype milled for us to drool over ? ?

Re: Discussion about possible aluminum transmission and part

Posted: Mon Jun 27, 2011 3:57 pm

by Charlie don't surf

No one said integrated motor spacers?